Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHAPTER 2<br />

intermediate oxidation product, i.e. the aldehyde or ketone. Au nanoparticles supported on<br />

nanosized CeO2 gave impressive results [96] with TOFs higher than 400 h ‐1 for 3‐octanol oxidation<br />

and >99 % selectivity. Often significantly lower reaction rates are reported. As an example, Enache et<br />

al. investigated a number of standard supports including SiO2, TiO2, CeO2 and activated carbon where<br />

TOFs were between 10 – 80 h ‐1 for benzyl alcohol oxidation at 100 °C [97] which settles gold catalysts<br />

in the proximity of silver catalysts (cf. Table 2‐1, entry 9 and 19). Many gold catalysts require a strong<br />

base in order to facilitate alcohol oxidation which is why basic supports often are beneficial for the<br />

Au catalyzed alcohol oxidation [7].<br />

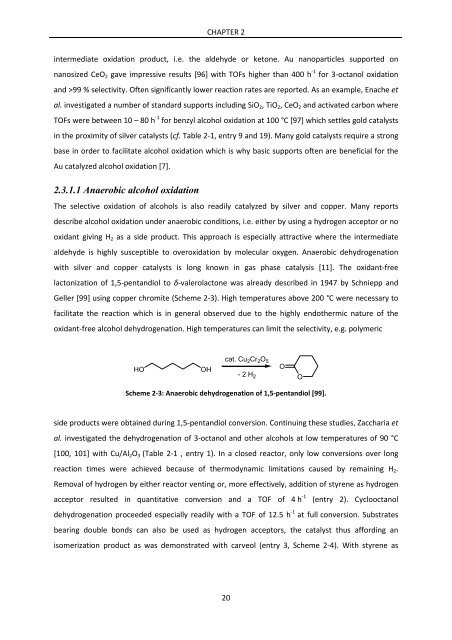

2.3.1.1 Anaerobic alcohol oxidation<br />

The selective oxidation of alcohols is also readily catalyzed by silver and copper. Many reports<br />

describe alcohol oxidation under anaerobic conditions, i.e. either by using a hydrogen acceptor or no<br />

oxidant giving H2 as a side product. This approach is especially attractive where the intermediate<br />

aldehyde is highly susceptible to overoxidation by molecular oxygen. Anaerobic dehydrogenation<br />

with silver and copper catalysts is long known in gas phase catalysis [11]. The oxidant‐free<br />

lactonization of 1,5‐pentandiol to δ‐valerolactone was already described in 1947 by Schniepp and<br />

Geller [99] using copper chromite (Scheme 2‐3). High temperatures above 200 °C were necessary to<br />

facilitate the reaction which is in general observed due to the highly endothermic nature of the<br />

oxidant‐free alcohol dehydrogenation. High temperatures can limit the selectivity, e.g. polymeric<br />

HO OH<br />

cat. Cu 2Cr 2O 5<br />

Scheme 2‐3: Anaerobic dehydrogenation of 1,5‐pentandiol [99].<br />

side products were obtained during 1,5‐pentandiol conversion. Continuing these studies, Zaccharia et<br />

al. investigated the dehydrogenation of 3‐octanol and other alcohols at low temperatures of 90 °C<br />

[100, 101] with Cu/Al2O3 (Table 2‐1 , entry 1). In a closed reactor, only low conversions over long<br />

reaction times were achieved because of thermodynamic limitations caused by remaining H2.<br />

Removal of hydrogen by either reactor venting or, more effectively, addition of styrene as hydrogen<br />

acceptor resulted in quantitative conversion and a TOF of 4 h ‐1 (entry 2). Cyclooctanol<br />

dehydrogenation proceeded especially readily with a TOF of 12.5 h ‐1 at full conversion. Substrates<br />

bearing double bonds can also be used as hydrogen acceptors, the catalyst thus affording an<br />

isomerization product as was demonstrated with carveol (entry 3, Scheme 2‐4). With styrene as<br />

20<br />

- 2 H 2<br />

O<br />

O