Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Leaching<br />

2+<br />

[Cu ] solv<br />

Al O<br />

2 3<br />

Al O<br />

2 3<br />

CHAPTER 2<br />

Al O<br />

2 3<br />

Al O<br />

2 3<br />

Isolated Cu 2+<br />

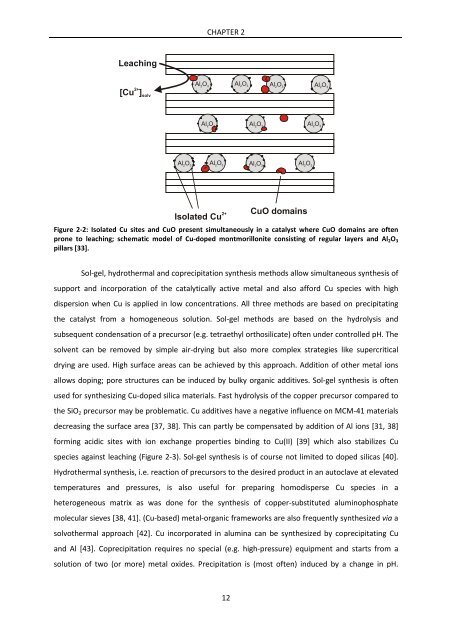

Figure 2‐2: Isolated Cu sites and CuO present simultaneously in a catalyst where CuO domains are often<br />

prone to leaching; schematic model of Cu‐doped montmorillonite consisting of regular layers and Al2O3<br />

pillars [33].<br />

Sol‐gel, hydrothermal and coprecipitation synthesis methods allow simultaneous synthesis of<br />

support and incorporation of the catalytically active metal and also afford Cu species with high<br />

dispersion when Cu is applied in low concentrations. All three methods are based on precipitating<br />

the catalyst from a homogeneous solution. Sol‐gel methods are based on the hydrolysis and<br />

subsequent condensation of a precursor (e.g. tetraethyl orthosilicate) often under controlled pH. The<br />

solvent can be removed by simple air‐drying but also more complex strategies like supercritical<br />

drying are used. High surface areas can be achieved by this approach. Addition of other metal ions<br />

allows doping; pore structures can be induced by bulky organic additives. Sol‐gel synthesis is often<br />

used for synthesizing Cu‐doped silica materials. Fast hydrolysis of the copper precursor compared to<br />

the SiO2 precursor may be problematic. Cu additives have a negative influence on MCM‐41 materials<br />

decreasing the surface area [37, 38]. This can partly be compensated by addition of Al ions [31, 38]<br />

forming acidic sites with ion exchange properties binding to Cu(II) [39] which also stabilizes Cu<br />

species against leaching (Figure 2‐3). Sol‐gel synthesis is of course not limited to doped silicas [40].<br />

Hydrothermal synthesis, i.e. reaction of precursors to the desired product in an autoclave at elevated<br />

temperatures and pressures, is also useful for preparing homodisperse Cu species in a<br />

heterogeneous matrix as was done for the synthesis of copper‐substituted aluminophosphate<br />

molecular sieves [38, 41]. (Cu‐based) metal‐organic frameworks are also frequently synthesized via a<br />

solvothermal approach [42]. Cu incorporated in alumina can be synthesized by coprecipitating Cu<br />

and Al [43]. Coprecipitation requires no special (e.g. high‐pressure) equipment and starts from a<br />

solution of two (or more) metal oxides. Precipitation is (most often) induced by a change in pH.<br />

12<br />

Al2O3 Al O<br />

Al O<br />

Al O<br />

2 3<br />

Al O<br />

2 3<br />

2 3<br />

Al O<br />

2 3<br />

CuO domains<br />

Al O<br />

2 3<br />

2 3