CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

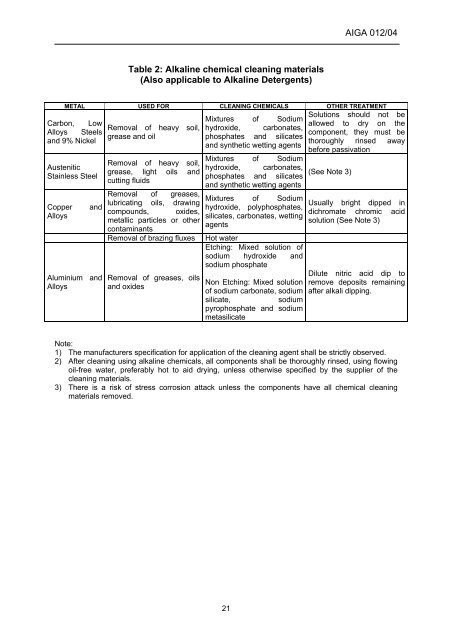

Table 2: Alkaline chemical cleaning materials<br />

(Also applicable to Alkaline Detergents)<br />

21<br />

<strong>AIGA</strong> 012/04<br />

METAL USED <strong>FOR</strong> <strong>CLEANING</strong> CHEMICALS OTHER TREATMENT<br />

Carbon, Low<br />

Alloys Steels<br />

and 9% Nickel<br />

Austenitic<br />

Stainless Steel<br />

Copper and<br />

Alloys<br />

Aluminium and<br />

Alloys<br />

Removal of heavy soil,<br />

grease and oil<br />

Removal of heavy soil,<br />

grease, light oils and<br />

cutting fluids<br />

Removal of greases,<br />

lubricating oils, drawing<br />

compounds, oxides,<br />

metallic particles or other<br />

contaminants<br />

Removal of brazing fluxes Hot water<br />

Removal of greases, oils<br />

and oxides<br />

Mixtures of Sodium<br />

hydroxide, carbonates,<br />

phosphates and silicates<br />

and synthetic wetting agents<br />

Mixtures of Sodium<br />

hydroxide, carbonates,<br />

phosphates and silicates<br />

and synthetic wetting agents<br />

Mixtures of Sodium<br />

hydroxide, polyphosphates,<br />

silicates, carbonates, wetting<br />

agents<br />

Etching: Mixed solution of<br />

sodium hydroxide and<br />

sodium phosphate<br />

Non Etching: Mixed solution<br />

of sodium carbonate, sodium<br />

silicate, sodium<br />

pyrophosphate and sodium<br />

metasilicate<br />

Solutions should not be<br />

allowed to dry on the<br />

component, they must be<br />

thoroughly rinsed away<br />

before passivation<br />

(See Note 3)<br />

Usually bright dipped in<br />

dichromate chromic acid<br />

solution (See Note 3)<br />

Dilute nitric acid dip to<br />

remove deposits remaining<br />

after alkali dipping.<br />

Note:<br />

1) The manufacturers specification for application of the cleaning agent shall be strictly observed.<br />

2) After cleaning using alkaline chemicals, all components shall be thoroughly rinsed, using flowing<br />

oil-free water, preferably hot to aid drying, unless otherwise specified by the supplier of the<br />

cleaning materials.<br />

3) There is a risk of stress corrosion attack unless the components have all chemical cleaning<br />

materials removed.