CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The amount of contaminants in a sample can be determined in three ways.<br />

- weight of residue (laboratory test)<br />

- volume of residue (laboratory test)<br />

- light transmission (laboratory test for qualitative figures)<br />

26<br />

<strong>AIGA</strong> 012/04<br />

This method is accurate in determining low amounts of oil or grease residues with small tolerances.<br />

6.2.4.1 Weight of Residue<br />

A known quantity (MS) of a representative sample of unfiltered used solvent is contained in a small<br />

weighed beaker and is evaporated to dryness being careful not to overheat the residue and the<br />

weight (m2) of the residue established. In the same manner the weight (in, ) of residue from a similar<br />

quantity of clean unused solvent is determined.<br />

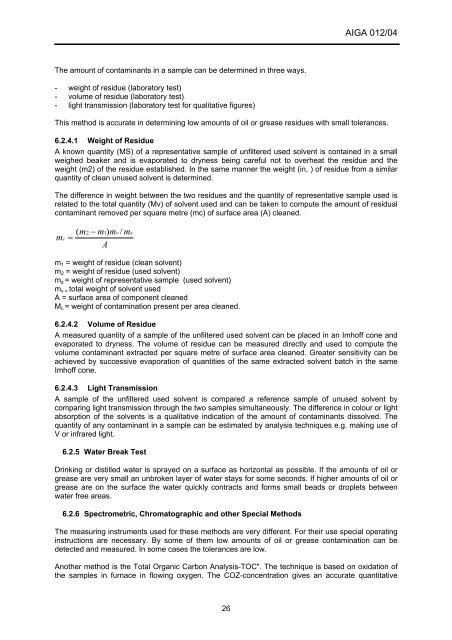

The difference in weight between the two residues and the quantity of representative sample used is<br />

related to the total quantity (Mv) of solvent used and can be taken to compute the amount of residual<br />

contaminant removed per square metre (mc) of surface area (A) cleaned.<br />

m<br />

c<br />

=<br />

m2<br />

− m ) mv<br />

/ m<br />

A<br />

( 1<br />

s<br />

m1 = weight of residue (clean solvent)<br />

m2 = weight of residue (used solvent)<br />

ms = weight of representative sample (used solvent)<br />

mv = total weight of solvent used<br />

A = surface area of component cleaned<br />

Mc = weight of contamination present per area cleaned.<br />

6.2.4.2 Volume of Residue<br />

A measured quantity of a sample of the unfiltered used solvent can be placed in an Imhoff cone and<br />

evaporated to dryness. The volume of residue can be measured directly and used to compute the<br />

volume contaminant extracted per square metre of surface area cleaned. Greater sensitivity can be<br />

achieved by successive evaporation of quantities of the same extracted solvent batch in the same<br />

Imhoff cone.<br />

6.2.4.3 Light Transmission<br />

A sample of the unfiltered used solvent is compared a reference sample of unused solvent by<br />

comparing light transmission through the two samples simultaneously. The difference in colour or light<br />

absorption of the solvents is a qualitative indication of the amount of contaminants dissolved. The<br />

quantity of any contaminant in a sample can be estimated by analysis techniques e.g. making use of<br />

V or infrared light.<br />

6.2.5 Water Break Test<br />

Drinking or distilled water is sprayed on a surface as horizontal as possible. If the amounts of oil or<br />

grease are very small an unbroken layer of water stays for some seconds. If higher amounts of oil or<br />

grease are on the surface the water quickly contracts and forms small beads or droplets between<br />

water free areas.<br />

6.2.6 Spectrometric, Chromatographic and other Special Methods<br />

The measuring instruments used for these methods are very different. For their use special operating<br />

instructions are necessary. By some of them low amounts of oil or grease contamination can be<br />

detected and measured. In some cases the tolerances are low.<br />

Another method is the Total Organic Carbon Analysis-TOC". The technique is based on oxidation of<br />

the samples in furnace in flowing oxygen. The COZ-concentration gives an accurate quantitative