CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

37<br />

<strong>AIGA</strong> 012/04<br />

An alternating current generates ultrasonic vibrations which give rise to cavitation bubbles in the<br />

liquid. When they implode, mechanical cleaning energy in the form of small jets is created.<br />

Cleaning of small parts can be performed in mesh baskets or in containers with holes, which are<br />

immersed into the main ultrasonic bath. Some of the ultrasonic energy is then lost however.<br />

Containers id baskets should not be made from soft material as they absorb much of the ultrasonic<br />

energy. The cleaning tune in ultrasonic baths is considerably porter compared to ordinary immersion<br />

cleaning.<br />

The liquid in the bath must be free from gas bubbles these absorb the ultrasonic energy. A pump<br />

design should be used which does not give rise to gas bubbles in the liquid. For the same reason, air<br />

agitation cannot be combined with ultrasonic energy. The rinsing and drying might be done in the<br />

same apparatus ( Fig 5 ), but is normally performed in separate stages.<br />

Applications:<br />

Ultrasonic cleaning is generally used for small and medium size parts. The method is not suitable for<br />

porous and soft parts because of their energy absorption properties.<br />

It is important that the ultrasonic waves reach all surfaces to be cleaned. The cleaning efficiency is<br />

strongly dependent on the shape, the quantity and the positioning in the bath of the parts to be<br />

cleaned.<br />

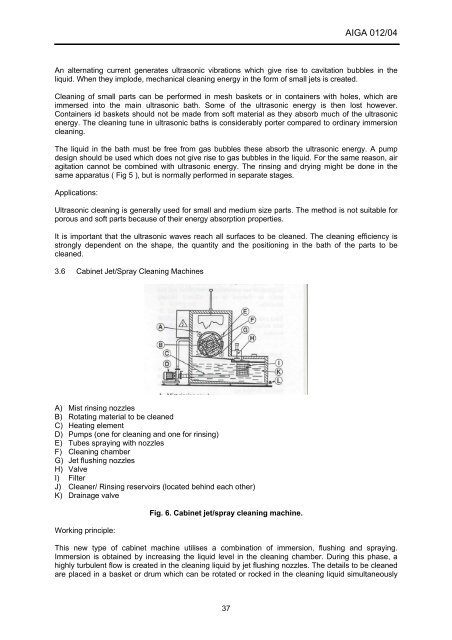

3.6 Cabinet Jet/Spray Cleaning Machines<br />

A) Mist rinsing nozzles<br />

B) Rotating material to be cleaned<br />

C) Heating element<br />

D) Pumps (one for cleaning and one for rinsing)<br />

E) Tubes spraying with nozzles<br />

F) Cleaning chamber<br />

G) Jet flushing nozzles<br />

H) Valve<br />

I) Filter<br />

J) Cleaner/ Rinsing reservoirs (located behind each other)<br />

K) Drainage valve<br />

Working principle:<br />

Fig. 6. Cabinet jet/spray cleaning machine.<br />

This new type of cabinet machine utilises a combination of immersion, flushing and spraying.<br />

Immersion is obtained by increasing the liquid level in the cleaning chamber. During this phase, a<br />

highly turbulent flow is created in the cleaning liquid by jet flushing nozzles. The details to be cleaned<br />

are placed in a basket or drum which can be rotated or rocked in the cleaning liquid simultaneously