CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

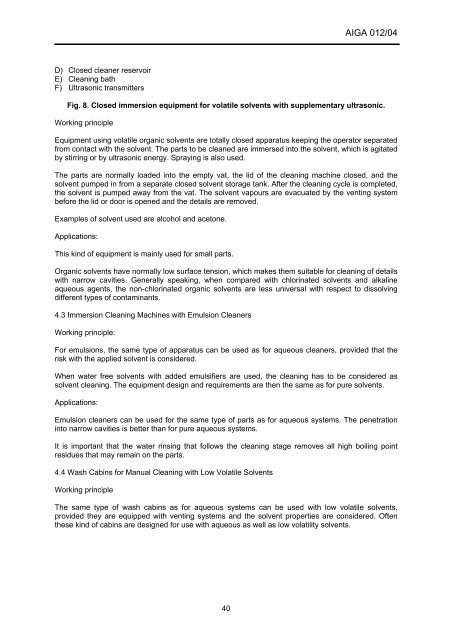

D) Closed cleaner reservoir<br />

E) Cleaning bath<br />

F) Ultrasonic transmitters<br />

40<br />

<strong>AIGA</strong> 012/04<br />

Fig. 8. Closed immersion equipment for volatile solvents with supplementary ultrasonic.<br />

Working principle<br />

Equipment using volatile organic solvents are totally closed apparatus keeping the operator separated<br />

from contact with the solvent. The parts to be cleaned are immersed into the solvent, which is agitated<br />

by stirring or by ultrasonic energy. Spraying is also used.<br />

The parts are normally loaded into the empty vat, the lid of the cleaning machine closed, and the<br />

solvent pumped in from a separate closed solvent storage tank. After the cleaning cycle is completed,<br />

the solvent is pumped away from the vat. The solvent vapours are evacuated by the venting system<br />

before the lid or door is opened and the details are removed.<br />

Examples of solvent used are alcohol and acetone.<br />

Applications:<br />

This kind of equipment is mainly used for small parts.<br />

Organic solvents have normally low surface tension, which makes them suitable for cleaning of details<br />

with narrow cavities. Generally speaking, when compared with chlorinated solvents and alkaline<br />

aqueous agents, the non-chlorinated organic solvents are less universal with respect to dissolving<br />

different types of contaminants.<br />

4.3 Immersion Cleaning Machines with Emulsion Cleaners<br />

Working principle:<br />

For emulsions, the same type of apparatus can be used as for aqueous cleaners, provided that the<br />

risk with the applied solvent is considered.<br />

When water free solvents with added emulsifiers are used, the cleaning has to be considered as<br />

solvent cleaning. The equipment design and requirements are then the same as for pure solvents.<br />

Applications:<br />

Emulsion cleaners can be used for the same type of parts as for aqueous systems. The penetration<br />

into narrow cavities is better than for pure aqueous systems.<br />

It is important that the water rinsing that follows the cleaning stage removes all high boiling point<br />

residues that may remain on the parts.<br />

4.4 Wash Cabins for Manual Cleaning with Low Volatile Solvents<br />

Working principle<br />

The same type of wash cabins as for aqueous systems can be used with low volatile solvents,<br />

provided they are equipped with venting systems and the solvent properties are considered. Often<br />

these kind of cabins are designed for use with aqueous as well as low volatility solvents.