CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

38<br />

<strong>AIGA</strong> 012/04<br />

with flushing / spraying from the nozzles. The powerful agitation and mechanical impact gives a very<br />

good cleaning effect, which also may be utilised for decreasing the concentration of chemicals and<br />

the cleaning temperature.<br />

The cleaning stage is followed by rinsing with water from a separate tank in the same unit. It can also<br />

be equipped with facilities for drying, oil separation and chemical dosage.<br />

The whole cleaning sequence as well as the temperature are automatically controlled and can easily<br />

be changed to suit different cleaning situations.<br />

Short over all cleaning times can be obtained. Total time including rinsing and drying is typically 8 - 12<br />

minutes.<br />

Applications:<br />

Small and medium size details can successfully be cleaned in this type of apparatus. Typical<br />

examples are closely packed details with complicated shapes, cavities, crevices etc.<br />

4 Cleaning Equipment for Organic Cleaners<br />

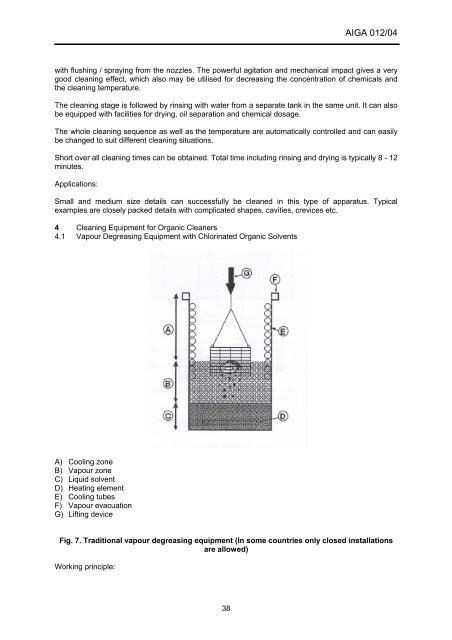

4.1 Vapour Degreasing Equipment with Chlorinated Organic Solvents<br />

A) Cooling zone<br />

B) Vapour zone<br />

C) Liquid solvent<br />

D) Heating element<br />

E) Cooling tubes<br />

F) Vapour evacuation<br />

G) Lifting device<br />

Fig. 7. Traditional vapour degreasing equipment (In some countries only closed installations<br />

are allowed)<br />

Working principle: