CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

CLEANING OF EQUIPMENT FOR OXYGEN SERVICE - AIGA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

39<br />

<strong>AIGA</strong> 012/04<br />

The chlorinated solvent is heated to its boiling point in the bottom of the vat with the vapour rising<br />

upwards. The parts to be cleaned are immersed in the vapour phase in the lower part of the vat (the<br />

vapour zone) where they are suspended during the cleaning process. The solvent condenses on the<br />

surface of the parts, dissolving oil and grease, which drain off together with the solvent, which<br />

accumulates in the bottom of the vat. The surplus of vapour is condensed on the cooled walls in the<br />

upper part of the vat (the cooling zone). Remaining vapour, if any, is evacuated through slots just<br />

below the upper edge of the vat.<br />

This self-distilling principle means that clean solvent condenses on the parts even if the solvent in the<br />

sump is heavily contaminated.<br />

During the cleaning procedure parts with cavities must be turned upside down for emptying of<br />

contaminated solvent.<br />

The cleaning stops when the temperature of -the parts reaches the boiling point of the solvent. If this<br />

happens before the parts are adequately cleaned, the parts have to be cooled down with cold solvent<br />

before the degreasing process can proceed.<br />

Vapour degreasing can be combined with ultra sonic immersion and spraying, usually in separate<br />

areas of the machine.<br />

Regular checks of the solvent in the sump according :o the solvent manufacturers recommendations<br />

is necessary to ensure that the condition of the solvent) being used is always suitable for safe and<br />

efficient use.<br />

Special precautions are necessary including the requirement of entry permits into a confined space,<br />

he use of suitable breathing apparatus and the wearing of protective clothing.<br />

Applications:<br />

Vapour degreasing can be applied to all kind of parts is the vapour can reach and condense on all<br />

surfaces. Problems may occur for small and thin details which ire quickly heated up to the boiling<br />

temperature.<br />

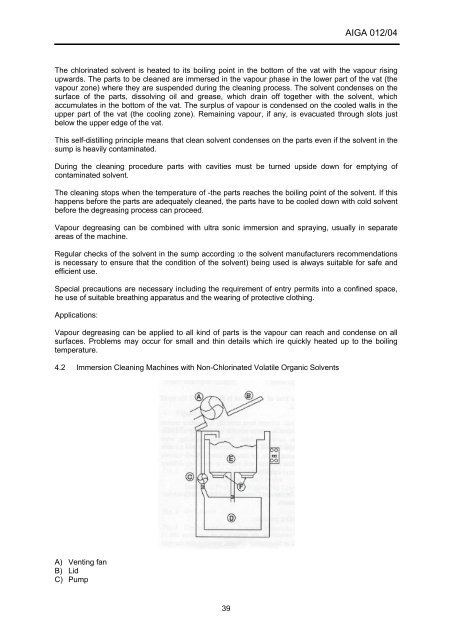

4.2 Immersion Cleaning Machines with Non-Chlorinated Volatile Organic Solvents<br />

A) Venting fan<br />

B) Lid<br />

C) Pump