Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

74<br />

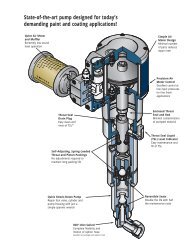

GRACO SEALANT AND ADHESIVE EQUIPMENT ❚ PUMPS AND PACKAGES<br />

5:1 Monark<br />

Air-Operated Piston Transfer Pump<br />

Performance Chart<br />

How to use this chart:<br />

Step 1: Locate the required fluid flow rate along<br />

bottom axis of chart, below.<br />

Step 2: Follow vertical line to the intersection with<br />

the solid curve (A, B, C or D – based on your air<br />

inlet pressure).<br />

Step 3: Follow to left axis to read fluid outlet<br />

pressure.<br />

Step 4: From Step 2, follow vertical line up or down<br />

to the intersection with the dotted line<br />

(A, B or C or D – based on your air inlet pressure)<br />

then follow to right axis to read air<br />

consumption.<br />

Example<br />

To obtain 2 gpm (7.5 lpm) at approximately 325 psi (22.4 bar,<br />

2.2 MPa) you will need 100 psi (7 bar, 0.7 MPa) of air pressure.<br />

The air consumption will be approximately 8 scfm.<br />

FLUID OUTLET PRESSURE psi (bar, MPa)<br />

1000<br />

(70, 7)<br />

800<br />

(56, 5.6)<br />

600<br />

(42, 4.2)<br />

400<br />

(28, 2.8)<br />

200<br />

(14, 1.4)<br />

A<br />

B<br />

C<br />

D<br />

5:1 Monark Performance<br />

0<br />

0<br />

gpm 0 1 2 3 4 5<br />

(lpm) (3.8) (7.6) (11.4) (15.2) (19.0)<br />

FLUID FLOW<br />

(Pump tested in No. 10 weight oil with inlet submerged)<br />

AIR PRESSURES LEGEND<br />

A = at 180 psi (12 bar, 1.2 MPa) Air Consumption<br />

B = at 100 psi (7 bar, 0.7 MPa) Fluid Flow<br />

C = at 70 psi (4.8 bar, 0.48 MPa)<br />

D = at 40 psi (2.7 bar, 0.27 MPa)<br />

C<br />

D<br />

B<br />

A<br />

Ordering Information<br />

Part Number Construction Packing<br />

218956 Drum/CS T<br />

224343 Stubby/SST UHMWPE/T<br />

224345 Stubby/SST UHMWPE/N<br />

224350 Drum/SST UHMWPE/T<br />

40<br />

(1.12)<br />

32<br />

(0.90)<br />

24<br />

(0.67)<br />

16<br />

(0.45)<br />

8<br />

(0.23)<br />

AIR CONSUMPTION scfm(m 3 /min)<br />

SIZE AND MATERIALS OF CONSTRUCTION<br />

N = Neoprene SST = 304 Stainless Steel<br />

L = Leather CS = Carbon Steel<br />

T = PTFE PE = Polyethylene