Letaba Biomass to Energy PDD - MyClimate

Letaba Biomass to Energy PDD - MyClimate

Letaba Biomass to Energy PDD - MyClimate

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

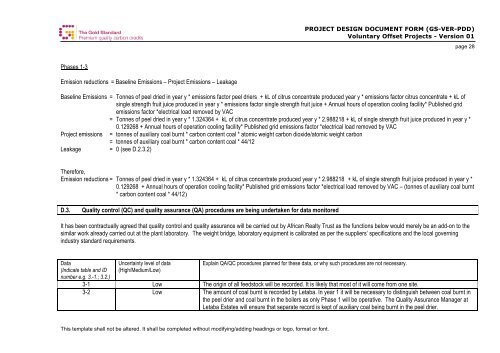

Phases 1-3<br />

Emission reductions = Baseline Emissions – Project Emissions – Leakage<br />

This template shall not be altered. It shall be completed without modifying/adding headings or logo, format or font.<br />

PROJECT DESIGN DOCUMENT FORM (GS-VER-<strong>PDD</strong>)<br />

Voluntary Offset Projects - Version 01<br />

Baseline Emissions = Tonnes of peel dried in year y * emissions fac<strong>to</strong>r peel driers + kL of citrus concentrate produced year y * emissions fac<strong>to</strong>r citrus concentrate + kL of<br />

single strength fruit juice produced in year y * emissions fac<strong>to</strong>r single strength fruit juice + Annual hours of operation cooling facility* Published grid<br />

emissions fac<strong>to</strong>r *electrical load removed by VAC<br />

= Tonnes of peel dried in year y * 1.324364 + kL of citrus concentrate produced year y * 2.988218 + kL of single strength fruit juice produced in year y *<br />

0.129268 + Annual hours of operation cooling facility* Published grid emissions fac<strong>to</strong>r *electrical load removed by VAC<br />

Project emissions = <strong>to</strong>nnes of auxiliary coal burnt * carbon content coal * a<strong>to</strong>mic weight carbon dioxide/a<strong>to</strong>mic weight carbon<br />

= <strong>to</strong>nnes of auxiliary coal burnt * carbon content coal * 44/12<br />

Leakage = 0 (see D.2.3.2)<br />

Therefore,<br />

Emission reductions = Tonnes of peel dried in year y * 1.324364 + kL of citrus concentrate produced year y * 2.988218 + kL of single strength fruit juice produced in year y *<br />

0.129268 + Annual hours of operation cooling facility* Published grid emissions fac<strong>to</strong>r *electrical load removed by VAC – (<strong>to</strong>nnes of auxiliary coal burnt<br />

* carbon content coal * 44/12)<br />

D.3. Quality control (QC) and quality assurance (QA) procedures are being undertaken for data moni<strong>to</strong>red<br />

It has been contractually agreed that quality control and quality assurance will be carried out by African Realty Trust as the functions below would merely be an add-on <strong>to</strong> the<br />

similar work already carried out at the plant labora<strong>to</strong>ry. The weight bridge, labora<strong>to</strong>ry equipment is calibrated as per the suppliers’ specifications and the local governing<br />

industry standard requirements.<br />

Data<br />

(Indicate table and ID<br />

number e.g. 3.-1.; 3.2.)<br />

Uncertainty level of data<br />

(High/Medium/Low)<br />

Explain QA/QC procedures planned for these data, or why such procedures are not necessary.<br />

3-1 Low The origin of all feeds<strong>to</strong>ck will be recorded. It is likely that most of it will come from one site.<br />

3-2 Low The amount of coal burnt is recorded by <strong>Letaba</strong>. In year 1 it will be necessary <strong>to</strong> distinguish between coal burnt in<br />

the peel drier and coal burnt in the boilers as only Phase 1 will be operative. The Quality Assurance Manager at<br />

<strong>Letaba</strong> Estates will ensure that separate record is kept of auxiliary coal being burnt in the peel drier.<br />

page 28