Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.4 Core package casting<br />

1.4.1 Introduction<br />

See also:<br />

AAM <strong>–</strong> Applications <strong>–</strong> 1 Power train > Engine > Cylinder block<br />

Literature:<br />

Smetan, H.: Kernpaketverfahren im <strong>Aluminium</strong>motorenguss, MTZ 61, 2000, No.10,<br />

P.712-715<br />

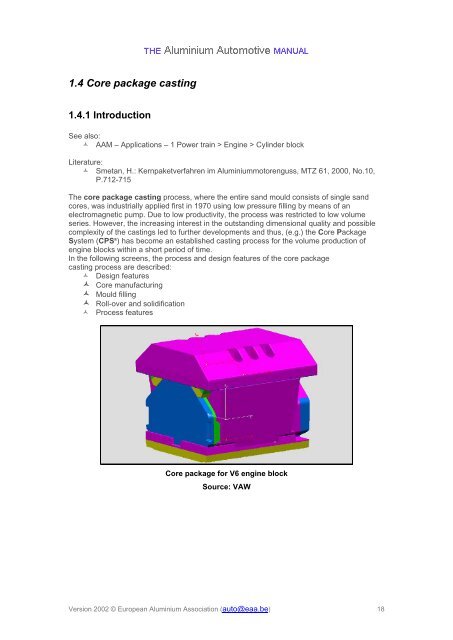

The core package casting process, where the entire sand mould consists of single sand<br />

cores, was industrially applied first in 1970 using low pressure filling by means of an<br />

electromagnetic pump. Due to low productivity, the process was restricted to low volume<br />

series. However, the increasing interest in the outstanding dimensional quality and possible<br />

complexity of the castings led to further developments and thus, (e.g.) the Core Package<br />

System (CPS ® ) has become an established casting process for the volume production of<br />

engine blocks within a short period of time.<br />

In the following screens, the process and design features of the core package<br />

casting process are described:<br />

Design features<br />

Core manufacturing<br />

Mould filling<br />

Roll-over and solidification<br />

Process features<br />

Core package for V6 engine block<br />

Source: VAW<br />

Version 2002 © <strong>European</strong> <strong>Aluminium</strong> <strong>Association</strong> (auto@eaa.be) 18