Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.7 High pressure die castings<br />

1.7.1 The HPDC process<br />

Filling speed and intensification pressure differentiates high-pressure die casting<br />

from most other casting processes.<br />

After liquid metal is transferred to the shot sleeve (s. fig. below), the plunger slowly<br />

closes to shut-off the filling port.<br />

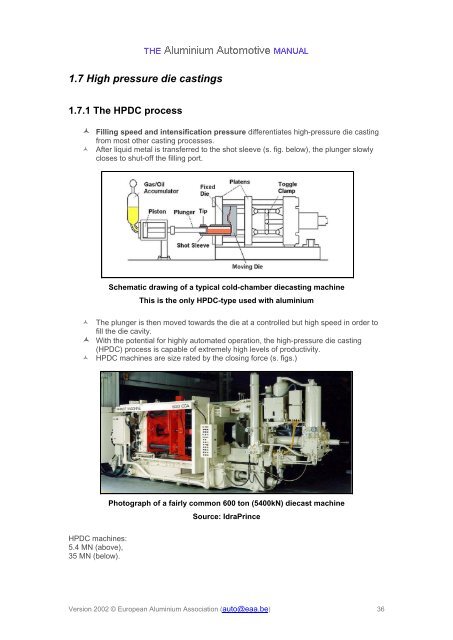

Schematic drawing of a typical cold-chamber diecasting machine<br />

This is the only HPDC-type used with aluminium<br />

The plunger is then moved towards the die at a controlled but high speed in order to<br />

fill the die cavity.<br />

With the potential for highly automated operation, the high-pressure die casting<br />

(HPDC) process is capable of extremely high levels of productivity.<br />

HPDC machines are size rated by the closing force (s. figs.)<br />

HPDC machines:<br />

5.4 MN (above),<br />

35 MN (below).<br />

Photograph of a fairly common 600 ton (5400kN) diecast machine<br />

Source: IdraPrince<br />

Version 2002 © <strong>European</strong> <strong>Aluminium</strong> <strong>Association</strong> (auto@eaa.be) 36