Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

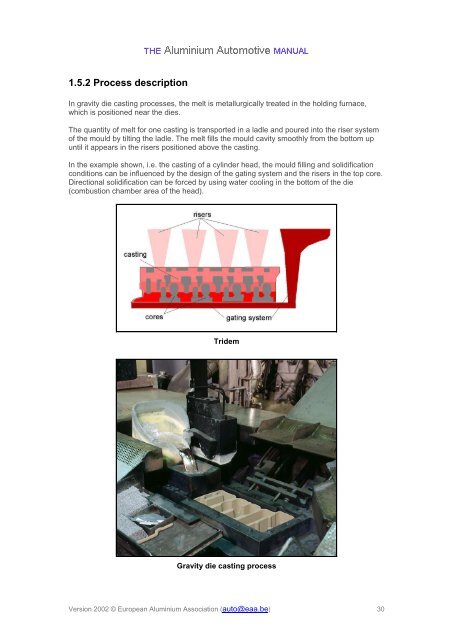

1.5.2 Process description<br />

In gravity die casting processes, the melt is metallurgically treated in the holding furnace,<br />

which is positioned near the dies.<br />

The quantity of melt for one casting is transported in a ladle and poured into the riser system<br />

of the mould by tilting the ladle. The melt fills the mould cavity smoothly from the bottom up<br />

until it appears in the risers positioned above the casting.<br />

In the example shown, i.e. the casting of a cylinder head, the mould filling and solidification<br />

conditions can be influenced by the design of the gating system and the risers in the top core.<br />

Directional solidification can be forced by using water cooling in the bottom of the die<br />

(combustion chamber area of the head).<br />

Tridem<br />

Gravity die casting process<br />

Version 2002 © <strong>European</strong> <strong>Aluminium</strong> <strong>Association</strong> (auto@eaa.be) 30