Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.4.3 Process description <strong>–</strong> Core manufacturing<br />

See also:<br />

AAM <strong>–</strong> Applications <strong>–</strong> 1 Power train > Engine > Cylinder block<br />

This process applies entirely resin bonded sand cores. Specifically, silica sand is used in the<br />

polyurethane cold-box process. The core package comprises also the whole running and<br />

feeding system. The core packages are, to a large extent, assembled automatically.<br />

Production lines with a capacity of up to 160 core packages per hour are currently in<br />

operation.<br />

Extremely tight tolerances are achievable, so that e.g. grey iron liners can be placed into the<br />

core package with a position tolerance of +-0.3 mm.<br />

Usually, the core packages are stored in a buffer and then fed into the casting line.<br />

Inserted parts such as grey iron liners can be preheated by induction coils in their final<br />

position in the core package prior to mould filling. This guarantees reproducible and<br />

repeatable conditions concerning the contact between the grey iron liners and the aluminium<br />

cast alloy.<br />

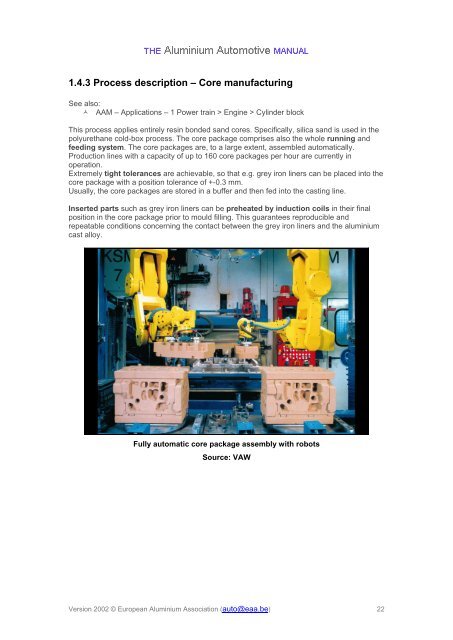

Fully automatic core package assembly with robots<br />

Source: VAW<br />

Version 2002 © <strong>European</strong> <strong>Aluminium</strong> <strong>Association</strong> (auto@eaa.be) 22