Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.4.2 Design features<br />

The question, which casting process is optimal for a given product, depends, beside other<br />

factors, on the desired complexity of the casting. Like all precision sand casting processes,<br />

the core package casting process offers almost unlimited possibilities for product design, e.g.<br />

for engine block castings:<br />

Complicated oil galleries and pre-cast oil channels to feed the crankshaft bearings.<br />

Complex exhaust gas return systems.<br />

Secondary air ducts.<br />

1 mm thick cooling water passages between the cylinders (facilitated by micro-core<br />

technology).<br />

<strong>Casting</strong>-in of cylinder liners.<br />

Hang-on and functional parts, such as thermostat housing, oil filter flange and splash wall can<br />

be integrated into the engine block with the core package process.<br />

Furthermore, the process provides extensive design freedom, for example in the design of<br />

undercuts, to reduce weight through the use of additional cores and/ or cavities and curved<br />

ports.<br />

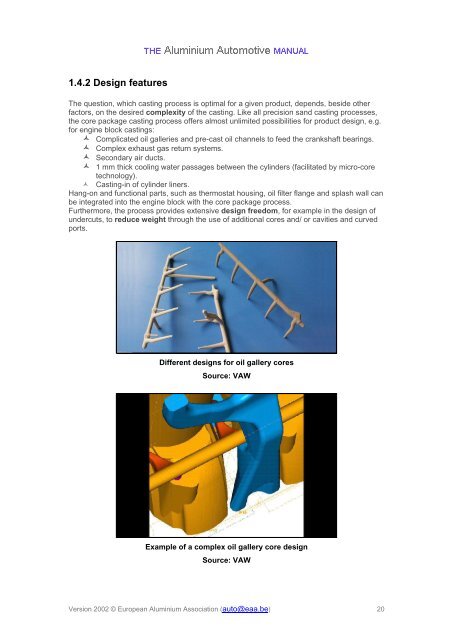

Different designs for oil gallery cores<br />

Source: VAW<br />

Example of a complex oil gallery core design<br />

Source: VAW<br />

Version 2002 © <strong>European</strong> <strong>Aluminium</strong> <strong>Association</strong> (auto@eaa.be) 20