Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

Manufacturing – Casting methods - European Aluminium Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

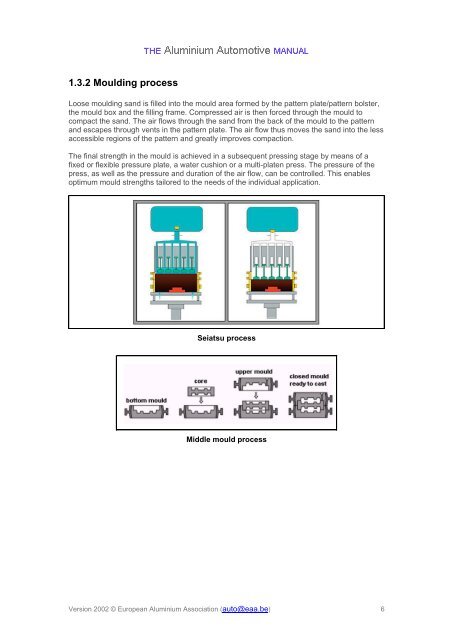

1.3.2 Moulding process<br />

Loose moulding sand is filled into the mould area formed by the pattern plate/pattern bolster,<br />

the mould box and the filling frame. Compressed air is then forced through the mould to<br />

compact the sand. The air flows through the sand from the back of the mould to the pattern<br />

and escapes through vents in the pattern plate. The air flow thus moves the sand into the less<br />

accessible regions of the pattern and greatly improves compaction.<br />

The final strength in the mould is achieved in a subsequent pressing stage by means of a<br />

fixed or flexible pressure plate, a water cushion or a multi-platen press. The pressure of the<br />

press, as well as the pressure and duration of the air flow, can be controlled. This enables<br />

optimum mould strengths tailored to the needs of the individual application.<br />

Seiatsu process<br />

Middle mould process<br />

Version 2002 © <strong>European</strong> <strong>Aluminium</strong> <strong>Association</strong> (auto@eaa.be) 6