instruction manual - BHEL Bhopal

instruction manual - BHEL Bhopal

instruction manual - BHEL Bhopal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Oil-filling of the tank is done through valve (12) at a low level on the<br />

transformer and at a maximum rate of 4-5 kL/hour. The pressure in the oil<br />

pipes shall be kept positive and shall be checked by a manometer 13 (if<br />

provided). When the oil-level has reached about 50 mm below the cover/the<br />

vacuum pump is stopped it is preferred that dry nitrogen is introduced in the<br />

tank by opening valve (8). Valve (7) is then opened .and valve (6) closed and<br />

the filling is continued in tank and conservator until the correct oil- level has<br />

been reached in the conservator.<br />

Conservator supplied with rubber air cell shall be filled according Clause<br />

2.6. For oil filling in diverter switch assembly of a OLTC refer leaflet (Vol.1).<br />

Separate vacuum-proof cooler system/radiators can be evacuated for<br />

about 1-2 hours and filled separately with purified and degassed oil. The oil is<br />

then circulated through the vacuum filter at least twice via drain valves as<br />

near as possible to the transformer. When the oil circulation has been completed<br />

the valves between coolers and main tank shall be opened.<br />

Care should be taken to keep all air release plugs and valves open to<br />

allow escape of trapped air during oil filling operation. These valves/plugs<br />

should be closed after completion of oil filling.<br />

2.5.7 HOT OIL CIRCULATION<br />

To facilitate oil-penetration and absorption of possible gas bubbles, the<br />

temperature of transformer shall-after completed oil-filling-be increased by<br />

circulating the oil through the vacuum filter and with circulation direction<br />

according to Fig. 2.4.<br />

The oil will be circulated through a vacuum filtration machine till the<br />

parameters are attained as per table 2.3 below.<br />

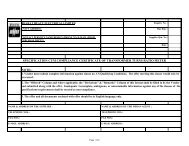

TABLE 2.3<br />

kV Class of<br />

Transformer<br />

Recommended Permissible Limits<br />

Electric Moisture Resistivity * Tan delta*<br />

Strength Content at 90oC at 90oC (BDV) in<br />

kV (min)<br />

ppm (Max) (Ohm-cm)<br />

Upto 72.5 40 25 1x1012 0.05<br />

145 50 20 1x1012 0.05<br />

245 and 420 60 15 1x1012 0.05<br />

* Subject to availability of testing facility at site.<br />

Method of test for Electric Strength and moisture content shall be as<br />

per IS:335.<br />

CAUTION:<br />

The temperature during oil circulation should not increase beyond 70 o C<br />

otherwise this may cause oxidation of oil.<br />

Prepared By Samvet Lahari, <strong>Bhopal</strong>. Phone- 5277412