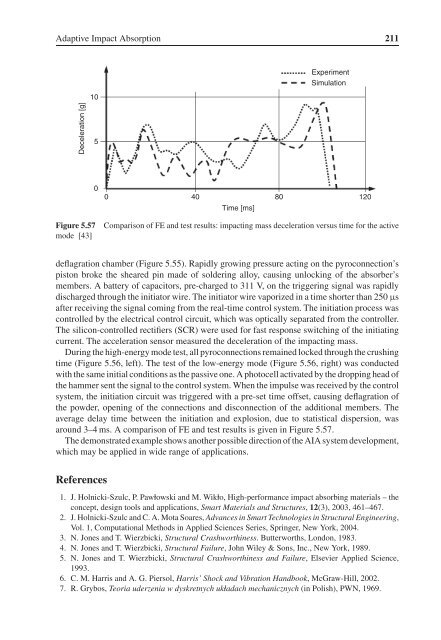

Adaptive Impact Absorption 211 Deceleration [g] 10 5 0 Experiment Simulation 0 40 80 120 Time [ms] Figure 5.57 Comparison of FE and test results: impacting mass deceleration versus time <strong>for</strong> the active mode [43] deflagration chamber (Figure 5.55). Rapidly growing pressure acting on the pyroconnection’s piston broke the sheared pin made of soldering alloy, causing unlocking of the absorber’s members. A battery of capacitors, pre-charged to 311 V, on the triggering signal was rapidly discharged through the initiator wire. The initiator wire vaporized in a time shorter than 250 μs after receiving the signal coming from the real-time control system. The initiation process was controlled by the electrical control circuit, which was optically separated from the controller. The silicon-controlled rectifiers (SCR) were used <strong>for</strong> fast response switching of the initiating current. The acceleration sensor measured the deceleration of the impacting mass. During the high-energy mode test, all pyroconnections remained locked through the crushing time (Figure 5.56, left). The test of the low-energy mode (Figure 5.56, right) was conducted with the same initial conditions as the passive one. A photocell activated by the dropping head of the hammer sent the signal to the control system. When the impulse was received by the control system, the initiation circuit was triggered with a pre-set time offset, causing deflagration of the powder, opening of the connections and disconnection of the additional members. The average delay time between the initiation and explosion, due to statistical dispersion, was around 3–4 ms. A comparison of FE and test results is given in Figure 5.57. The demonstrated example shows another possible direction of the AIA system development, which may be applied in wide range of applications. References 1. J. Holnicki-Szulc, P. Paw̷lowski and M. Wik̷lo, High-per<strong>for</strong>mance impact absorbing materials – the concept, design tools and applications, Smart Materials and Structures, 12(3), 2003, 461–467. 2. J. Holnicki-Szulc and C. A. Mota Soares, Advances in Smart Technologies in Structural Engineering, Vol. 1, Computational Methods in Applied Sciences Series, Springer, New York, 2004. 3. N. Jones and T. Wierzbicki, Structural Crashworthiness. Butterworths, London, 1983. 4. N. Jones and T. Wierzbicki, Structural Failure, John Wiley & Sons, Inc., New York, 1989. 5. N. Jones and T. Wierzbicki, Structural Crashworthiness and Failure, Elsevier Applied Science, 1993. 6. C. M. Harris and A. G. Piersol, Harris’ Shock and Vibration Handbook, McGraw-Hill, 2002. 7. R. Grybos, Teoria uderzenia w dyskretnych uk̷ladach mechanicznych (in Polish), PWN, 1969.

212 Smart Technologies <strong>for</strong> Safety Engineering 8. G. Miku̷lowski and L. Jankowski, Adaptive landing gear: optimum control strategy and improvement potential, in Proceedings of ISMA 2006 (ed. P. Sas M. De Munck), Leuven, 2006. 9. N. S. Currey, Aircraft Landing Gear Design: Principles and Practices, AIAA, Washington, DC, 1988. 10. B. Milwitzky and F. E. Cook, Analysis of landing gear behavior, Technical Report 1154, NACA, 1953. 11. R. Freymann, Actively damped landing gear system, in AGARD CP-484 Ref. 20, Proceedings of the 71st Meeting of the AGARD Structures and Materials Panel, October 1990. 12. J. R. McGehee and H. D. Carden, Active control landing gear <strong>for</strong> ground load alleviation, in AGARD Conference Proceedings 384 FMP Symposium, Toronto, 1984. 13. J. R. McGehee and H. D. Carden, Analytical investigation of the landing dynamics of a large airplane with a load-control system in the main landing gear, Technical Report 1555, NASA, 1979. 14. L. G. Horta, R. H. Daugherty and V. J. Martinson, Actively controlled landing gear <strong>for</strong> aircraft vibration reduction, Technical Report NASA-99-ceas-lgh, NASA, 1999. 15. L. G. Horta, R. H. Daugherty and V. J. Martinson, Modeling and validation of a Navy A6-Intruder actively controlled landing gear system, Technical Report TP-1999-209124, NASA, 1999. 16. Adaptive landing gears <strong>for</strong> improved impact absorption, ADLAND, EU FP6 Project IST-FP6-2002- Aero-1-502793-STREP, http://<strong>smart</strong>.ippt.gov.pl/adland. 17. D. Batterbee, N. D. Sims, Z. Wo̷lejsza and A. Lafitte, Magnetorheological landing gear design: a feasibility study <strong>for</strong> small and large-scale aircraft, in Proceedings of ISMA 2006 (ed. P. Sas M. De Munck), Leuven, 2006. 18. J. D. Carlson, Introduction to magnetorheological fluids, in Proceedings of SMART”01 Workshop, Warsaw, 2001. 19. H. Gavin, J. Hoagg and M. Dobossy, Optimal design of MR dampers, in Optimal Design of MR Dampers, Proceedings of U.S.–Japan Workshop on Smart Structures <strong>for</strong> Improved Seismic Per<strong>for</strong>mance in Urban Regions (ed. K. Kawashima, B.F. Spencer and Y. Suzuki), Seattle, Washington, 2001. 20. Rexroth Bosch Group, 2007, http://www.boschrexroth.com. 21. Moog Inc., 2007, http://www.moog.com. 22. K. Seku̷la, G. Miku̷lowski and J. Holnicki-Szulc, Real time dynamic mass identification, in Proceedings of the Third European Workshop on Structural Health Monitoring (ed. A. Guemes Granada), 2006. 23. G. Miku̷lowski and J. Holnicki-Szulc, Fast controller and control algorithms <strong>for</strong> MR based adaptive impact absorbers – <strong>for</strong>ce based control, Machine Dynamics Problems, 30(2), 2006, 113–122. 24. Federal Aviation Regulations (FAR), Part 23 – Airworthiness Standards: Normal, Utility, Acrobatic and Commuter Category Airplanes. 25. I23 Technical Specification, Institute of Aviation, Warsaw, Poland. 26. D. Batterbee, N. D. Sims and R. Stanway, ADLAND Report: Annex USFD-1(a): oleo-pneumatic shock absorber modeling and initial MR device sizing, Technical Report, University of Sheffield, 2004. 27. G. Miku̷lowski and L. Jankowski, Adaptive landing gear: optimum control strategy and potential <strong>for</strong> improvement, Shock and Vibration (submitted). 28. G. Miku̷lowski and J. Holnicki-Szulc, Adaptive landing gear concept – feedback control validation, Smart Materials and Structures (to be published). 29. I. Yeh, L. Chai and N. Saha, Application of ALE to airbag deployment simulation, International Journal of Vehicle Safety, 1(4), 2006, 348–365. 30. G. J. Van Wylen and R. E. Sonntag, Fundamentals of Classical Thermodynamics, John Wiley & Sons, Ltd, Chichester, 1978. 31. ABAQUS, User’s Manual, Version 6.5, Hibbitt, Karlsson and Sorensen, Providence, Rhode Island, 2005. 32. T. Belytschko, W. K. Liu and B. Moran, Nonlinear Finite Elements <strong>for</strong> Continua and Structures, John Wiley & Sons, Ltd, Chichester, 2000.

- Page 2 and 3:

SMART TECHNOLOGIES FOR SAFETY ENGIN

- Page 4 and 5:

Copyright C○ 2008 John Wiley & So

- Page 6 and 7:

vi Contents 2.7 Versatility of VDM

- Page 8 and 9:

viii Contents 6 VDM-Based Remodelin

- Page 10 and 11:

Preface The contents of this book c

- Page 12 and 13:

xiv About the Authors The team of s

- Page 14 and 15:

Organization of the Book The book h

- Page 16 and 17:

1 Introduction to Smart Technologie

- Page 18 and 19:

Introduction to Smart Technologies

- Page 20 and 21:

Introduction to Smart Technologies

- Page 22 and 23:

Introduction to Smart Technologies

- Page 24 and 25:

Introduction to Smart Technologies

- Page 26 and 27:

12 Smart Technologies for Safety En

- Page 28 and 29:

14 Smart Technologies for Safety En

- Page 30 and 31:

16 Smart Technologies for Safety En

- Page 32 and 33:

18 Smart Technologies for Safety En

- Page 34 and 35:

20 Smart Technologies for Safety En

- Page 36 and 37:

22 Smart Technologies for Safety En

- Page 38 and 39:

24 Smart Technologies for Safety En

- Page 40 and 41:

26 Smart Technologies for Safety En

- Page 42 and 43:

28 Smart Technologies for Safety En

- Page 44 and 45:

30 Smart Technologies for Safety En

- Page 46 and 47:

32 Smart Technologies for Safety En

- Page 48 and 49:

34 Smart Technologies for Safety En

- Page 50 and 51:

3 VDM-Based Health Monitoring of En

- Page 52 and 53:

VDM-Based Health Monitoring 39 3.2

- Page 54 and 55:

VDM-Based Health Monitoring 41 When

- Page 56 and 57:

VDM-Based Health Monitoring 43 appr

- Page 58 and 59:

VDM-Based Health Monitoring 45 (7)

- Page 60 and 61:

VDM-Based Health Monitoring 47 μ i

- Page 62 and 63:

VDM-Based Health Monitoring 49 μ A

- Page 64 and 65:

VDM-Based Health Monitoring 51 Figu

- Page 66 and 67:

VDM-Based Health Monitoring 53 by a

- Page 68 and 69:

VDM-Based Health Monitoring 55 Figu

- Page 70 and 71:

VDM-Based Health Monitoring 57 axia

- Page 72 and 73:

axial strain 3,2 2,4 1,6 0,8 0 −0

- Page 74 and 75:

(a) (b) (c) Figure 3.27 (a) Screw c

- Page 76 and 77:

VDM-Based Health Monitoring 63 The

- Page 78 and 79:

VDM-Based Health Monitoring 65 μ i

- Page 80 and 81:

VDM-Based Health Monitoring 67 1 3

- Page 82 and 83:

VDM-Based Health Monitoring 69 3’

- Page 84 and 85:

VDM-Based Health Monitoring 71 1.95

- Page 86 and 87:

VDM-Based Health Monitoring 73 form

- Page 88 and 89:

VDM-Based Health Monitoring 75 Q Q

- Page 90 and 91:

VDM-Based Health Monitoring 77 Note

- Page 92 and 93:

VDM-Based Health Monitoring 79 wate

- Page 94 and 95:

VDM-Based Health Monitoring 81 0 -0

- Page 96 and 97:

VDM-Based Health Monitoring 83 −0

- Page 98 and 99:

VDM-Based Health Monitoring 85 impl

- Page 100 and 101:

VDM-Based Health Monitoring 87 give

- Page 102 and 103:

VDM-Based Health Monitoring 89 sour

- Page 104 and 105:

VDM-Based Health Monitoring 91 Rela

- Page 106 and 107:

VDM-Based Health Monitoring 93 The

- Page 108 and 109:

VDM-Based Health Monitoring 95 loca

- Page 110 and 111:

VDM-Based Health Monitoring 97 The

- Page 112 and 113:

VDM-Based Health Monitoring 99 1.0

- Page 114 and 115:

VDM-Based Health Monitoring 101 8.

- Page 116 and 117:

VDM-Based Health Monitoring 103 55.

- Page 118 and 119:

106 Smart Technologies for Safety E

- Page 120 and 121:

108 Smart Technologies for Safety E

- Page 122 and 123:

110 Smart Technologies for Safety E

- Page 124 and 125:

112 Smart Technologies for Safety E

- Page 126 and 127:

114 Smart Technologies for Safety E

- Page 128 and 129:

116 Smart Technologies for Safety E

- Page 130 and 131:

118 Smart Technologies for Safety E

- Page 132 and 133:

120 Smart Technologies for Safety E

- Page 134 and 135:

122 Smart Technologies for Safety E

- Page 136 and 137:

124 Smart Technologies for Safety E

- Page 138 and 139:

126 Smart Technologies for Safety E

- Page 140 and 141:

128 Smart Technologies for Safety E

- Page 142 and 143:

130 Smart Technologies for Safety E

- Page 144 and 145:

132 Smart Technologies for Safety E

- Page 146 and 147:

134 Smart Technologies for Safety E

- Page 148 and 149:

136 Smart Technologies for Safety E

- Page 150 and 151:

138 Smart Technologies for Safety E

- Page 152 and 153:

140 Smart Technologies for Safety E

- Page 154 and 155:

142 Smart Technologies for Safety E

- Page 156 and 157:

144 Smart Technologies for Safety E

- Page 158 and 159:

146 Smart Technologies for Safety E

- Page 160 and 161:

148 Smart Technologies for Safety E

- Page 162 and 163:

150 Smart Technologies for Safety E

- Page 164 and 165:

5 Adaptive Impact Absorption Piotr

- Page 166 and 167:

Adaptive Impact Absorption 155 Fina

- Page 168 and 169:

Adaptive Impact Absorption 157 σ 1

- Page 170 and 171:

Adaptive Impact Absorption 159 acce

- Page 172 and 173: Adaptive Impact Absorption 161 norm

- Page 174 and 175: Adaptive Impact Absorption 163 Figu

- Page 176 and 177: Adaptive Impact Absorption 165 Zone

- Page 178 and 179: Adaptive Impact Absorption 167 gas

- Page 180 and 181: Adaptive Impact Absorption 169 moun

- Page 182 and 183: Adaptive Impact Absorption 171 of t

- Page 184 and 185: Adaptive Impact Absorption 173 disp

- Page 186 and 187: Adaptive Impact Absorption 175 comp

- Page 188 and 189: Adaptive Impact Absorption 177 of t

- Page 190 and 191: Adaptive Impact Absorption 179 F VD

- Page 192 and 193: Adaptive Impact Absorption 181 forc

- Page 194 and 195: Adaptive Impact Absorption 183 Tabl

- Page 196 and 197: Adaptive Impact Absorption 185 Curr

- Page 198 and 199: Adaptive Impact Absorption 187 (a)

- Page 200 and 201: Adaptive Impact Absorption 189 Vect

- Page 202 and 203: Adaptive Impact Absorption 191 wher

- Page 204 and 205: Adaptive Impact Absorption 193 (a)

- Page 206 and 207: Adaptive Impact Absorption 195 time

- Page 208 and 209: Adaptive Impact Absorption 197 Pres

- Page 210 and 211: Adaptive Impact Absorption 199 towe

- Page 212 and 213: Adaptive Impact Absorption 201 Tabl

- Page 214 and 215: Adaptive Impact Absorption 203 Pres

- Page 216 and 217: Adaptive Impact Absorption 205 5.6.

- Page 218 and 219: Adaptive Impact Absorption 207 Unkn

- Page 220 and 221: Adaptive Impact Absorption 209 Figu

- Page 224 and 225: Adaptive Impact Absorption 213 33.

- Page 226 and 227: 216 Smart Technologies for Safety E

- Page 228 and 229: 218 Smart Technologies for Safety E

- Page 230 and 231: 220 Smart Technologies for Safety E

- Page 232 and 233: 222 Smart Technologies for Safety E

- Page 234 and 235: 224 Smart Technologies for Safety E

- Page 236 and 237: 226 Smart Technologies for Safety E

- Page 238 and 239: 228 Smart Technologies for Safety E

- Page 240 and 241: 230 Smart Technologies for Safety E

- Page 242 and 243: 232 Smart Technologies for Safety E

- Page 244 and 245: 234 Smart Technologies for Safety E

- Page 246 and 247: 236 Smart Technologies for Safety E

- Page 248 and 249: 238 Smart Technologies for Safety E

- Page 250 and 251: 240 Smart Technologies for Safety E

- Page 252 and 253: 242 Smart Technologies for Safety E

- Page 254 and 255: 244 Smart Technologies for Safety E

- Page 256 and 257: 246 Smart Technologies for Safety E

- Page 258 and 259: 248 Smart Technologies for Safety E

- Page 260 and 261: 7 Adaptive Damping of Vibration by

- Page 262 and 263: Adaptive Damping of Vibration 253 x

- Page 264 and 265: Adaptive Damping of Vibration 255 t

- Page 266 and 267: Adaptive Damping of Vibration 257 K

- Page 268 and 269: Adaptive Damping of Vibration 259 M

- Page 270 and 271: Adaptive Damping of Vibration 261 w

- Page 272 and 273:

Adaptive Damping of Vibration 263 1

- Page 274 and 275:

Adaptive Damping of Vibration 265 R

- Page 276 and 277:

Adaptive Damping of Vibration 267 1

- Page 278 and 279:

270 Smart Technologies for Safety E

- Page 280 and 281:

272 Smart Technologies for Safety E

- Page 282 and 283:

274 Smart Technologies for Safety E

- Page 284 and 285:

276 Smart Technologies for Safety E

- Page 286 and 287:

278 Smart Technologies for Safety E

- Page 288 and 289:

280 Smart Technologies for Safety E

- Page 290 and 291:

282 Smart Technologies for Safety E

- Page 292 and 293:

284 Smart Technologies for Safety E

- Page 294 and 295:

286 Smart Technologies for Safety E

- Page 296 and 297:

288 Smart Technologies for Safety E

- Page 298 and 299:

290 Smart Technologies for Safety E

- Page 300 and 301:

292 Smart Technologies for Safety E

- Page 302 and 303:

294 Smart Technologies for Safety E

- Page 304 and 305:

296 Smart Technologies for Safety E

- Page 306 and 307:

298 Smart Technologies for Safety E

- Page 308 and 309:

300 Smart Technologies for Safety E

- Page 310 and 311:

302 Smart Technologies for Safety E

- Page 312 and 313:

304 Smart Technologies for Safety E

- Page 314 and 315:

306 Smart Technologies for Safety E

- Page 316 and 317:

308 Smart Technologies for Safety E

- Page 318 and 319:

310 Smart Technologies for Safety E

- Page 320 and 321:

312 Smart Technologies for Safety E

- Page 322 and 323:

314 Smart Technologies for Safety E

- Page 324 and 325:

316 Smart Technologies for Safety E

- Page 326 and 327:

318 Smart Technologies for Safety E

- Page 328 and 329:

320 Smart Technologies for Safety E

- Page 330 and 331:

Acknowledgements Parts of Section

- Page 332 and 333:

Acknowledgements 325 Parts of Chap

- Page 334 and 335:

328 Index Control strategy (Continu

- Page 336 and 337:

330 Index Modification coefficient

- Page 338:

332 Index System analogies, 29, 68,