- Page 1 and 2:

4-1 [S100] SPECIFICATION AND SERVIC

- Page 3 and 4:

4-1 [C100] COMPONENT PARTS 1. Front

- Page 5 and 6:

4-1 [C200] COMPONENT PARTS 2. Rear

- Page 7 and 8:

4-1 [W1B1] SERVICE PROCEDURE 1. On-

- Page 9 and 10:

4-1 [W1B3] SERVICE PROCEDURE 1. On-

- Page 11 and 12:

4-1 [W1B6] SERVICE PROCEDURE 1. On-

- Page 13 and 14:

4-1 [W2A0] SERVICE PROCEDURE 2. Fro

- Page 15 and 16:

4-1 [W2E0] SERVICE PROCEDURE 2. Fro

- Page 17 and 18:

4-1 [W4A0] SERVICE PROCEDURE 4. Fro

- Page 19 and 20:

4-1 [W4C2] SERVICE PROCEDURE 4. Fro

- Page 21 and 22:

4-1 [W5A0] SERVICE PROCEDURE 5. Fro

- Page 23 and 24:

4-1 [W6B0] SERVICE PROCEDURE 6. Fro

- Page 25 and 26:

4-1 [W7B1] SERVICE PROCEDURE 7. Rea

- Page 27 and 28:

4-1 [W7E0] SERVICE PROCEDURE 7. Rea

- Page 29 and 30:

4-1 [W8B0] SERVICE PROCEDURE 8. Lat

- Page 31 and 32:

4-1 [W8E0] SERVICE PROCEDURE 8. Lat

- Page 33 and 34:

4-1 [W9B0] SERVICE PROCEDURE 9. Rea

- Page 35 and 36:

4-1 [W10B0] SERVICE PROCEDURE 10. R

- Page 37 and 38:

4-1 [W11C0] SERVICE PROCEDURE 11. R

- Page 39 and 40:

4-1 DIAGNOSTICS MEMO: 40

- Page 41 and 42:

3. Front Drive Shaft Assembly Model

- Page 43 and 44:

1. Front Axle (1) Baffle plate (SFJ

- Page 45 and 46:

1. Front Axle A: REMOVAL 1) Disconn

- Page 47 and 48:

3) Remove disc cover from housing.

- Page 49 and 50:

11) Attach hub to ST1 securely. 12)

- Page 51 and 52:

8) Disconnect parking brake cable e

- Page 53 and 54:

12) Remove bolts which secure later

- Page 55 and 56:

3) Clean housing interior completel

- Page 57 and 58:

10) Bleed air from brake system. 1

- Page 59 and 60:

2. REAR DRIVE SHAFT 1) Disconnect g

- Page 61 and 62: 8) Place alignment mark on trunnion

- Page 63 and 64: 3) Apply a coat of specified grease

- Page 65 and 66: 3) Insert DOJ cage onto shaft. NOTE

- Page 67 and 68: CAUTION: Use a new axle nut. Alwa

- Page 69 and 70: 5. Steel Wheel and Tire A: INSPECTI

- Page 71 and 72: 8. Tire Rotation If tires are maint

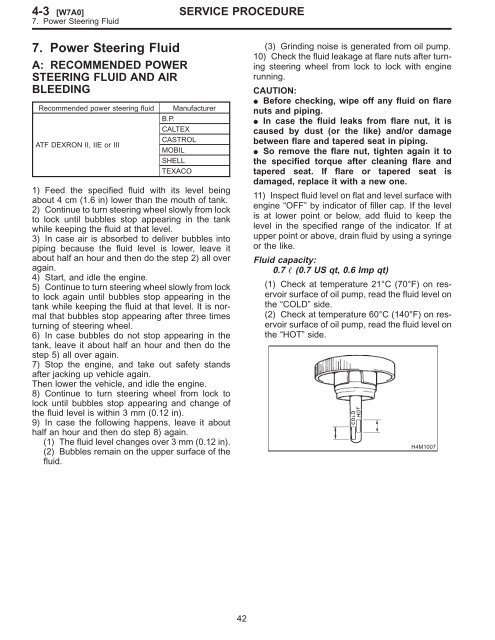

- Page 73 and 74: 4-3 [S1A0] SPECIFICATIONS AND SERVI

- Page 75 and 76: 4-3 [S1C0] SPECIFICATIONS AND SERVI

- Page 77 and 78: 4-3 [C200] COMPONENT PARTS 2. Power

- Page 79 and 80: 4-3 [C300] COMPONENT PARTS 3. Power

- Page 81 and 82: 4-3 [W2B0] SERVICE PROCEDURE 2. Til

- Page 83 and 84: 4-3 [W2D0] SERVICE PROCEDURE 2. Til

- Page 85 and 86: 4-3 [W3A0] SERVICE PROCEDURE 3. Ste

- Page 87 and 88: 4-3 [W3C0] SERVICE PROCEDURE 3. Ste

- Page 89 and 90: 4-3 [W3C3] SERVICE PROCEDURE 3. Ste

- Page 91 and 92: 4-3 [W3D0] SERVICE PROCEDURE 3. Ste

- Page 93 and 94: 4-3 [W3F0] SERVICE PROCEDURE 3. Ste

- Page 95 and 96: 4-3 [W4B0] SERVICE PROCEDURE 4. Con

- Page 97 and 98: 4-3 [W4C2] SERVICE PROCEDURE 4. Con

- Page 99 and 100: 4-3 [W4D1] SERVICE PROCEDURE 4. Con

- Page 101 and 102: 4-3 [W5A0] SERVICE PROCEDURE 5. Pip

- Page 103 and 104: 4-3 [W5C0] SERVICE PROCEDURE 5. Pip

- Page 105 and 106: 4-3 [W6A0] SERVICE PROCEDURE 6. Oil

- Page 107 and 108: 4-3 [W6B1] SERVICE PROCEDURE 6. Oil

- Page 109 and 110: 4-3 [W6D0] SERVICE PROCEDURE 6. Oil

- Page 111: 4-3 [W6E0] SERVICE PROCEDURE 6. Oil

- Page 115 and 116: 4-3 [K1B0] DIAGNOSTICS 1. Power Ste

- Page 117 and 118: 4-3 [K1C0] DIAGNOSTICS 1. Power Ste

- Page 119 and 120: 4-3 [K1C0] DIAGNOSTICS 1. Power Ste

- Page 121 and 122: 4-3 [K1E0] DIAGNOSTICS 1. Power Ste

- Page 123 and 124: 4-3 [K1F0] DIAGNOSTICS 1. Power Ste

- Page 125 and 126: 4-3 DIAGNOSTICS MEMO: 54

- Page 127 and 128: 2. 2500 cc MODEL SPECIFICATIONS AND

- Page 129 and 130: 1. Front Disc Brake A: EXCEPT 2500

- Page 131 and 132: 2. Rear Disc Brake (1) Caliper body

- Page 133 and 134: 4. Master Cylinder A: WITH ABS VEHI

- Page 135 and 136: 5. Brake Booster A: MODELS WITH ABS

- Page 137 and 138: B: ABS CONTROL MODULE AND HYDRAULIC

- Page 139 and 140: 1. Front Disc Brake A: ON-CAR SERVI

- Page 141 and 142: 5) Remove disc rotor from hub. NOTE

- Page 143 and 144: 1) Clean mud and foreign particles

- Page 145 and 146: 1) Clean mud and foreign particles

- Page 147 and 148: F: INSTALLATION 1) Install disc rot

- Page 149 and 150: B: REMOVAL (1) Caliper body (2) Air

- Page 151 and 152: E: ASSEMBLY 1) Clean caliper body i

- Page 153 and 154: NOTE: If it is difficult to remove

- Page 155 and 156: D: ASSEMBLY 1. WHEEL CYLINDER 1) Cl

- Page 157 and 158: 4. Parking Brake (Rear Disc Brake)

- Page 159 and 160: D: ADJUSTMENT 1. SHOE CLEARANCE 1)

- Page 161 and 162: 6. Brake Booster A: REMOVAL 1) Remo

- Page 163 and 164:

3. OPERATION CHECK 1) With engine o

- Page 165 and 166:

7) While holding hexagonal part of

- Page 167 and 168:

11) Remove bolt and clamp from rear

- Page 169 and 170:

11. Brake Fluid A: REPLACEMENT CAUT

- Page 171 and 172:

CAUTION: Do not disassemble or adju

- Page 173 and 174:

3. OUTPUT VOLTAGE Output voltage ca

- Page 175 and 176:

14. ABS Control Module and Hydrauli

- Page 177 and 178:

9) Remove air bleeder screws from t

- Page 179 and 180:

SERVICE PROCEDURE 4. CONDITIONS FOR

- Page 181 and 182:

15B2 : CHECK G SENSOR. Measure volt

- Page 183 and 184:

1. Entire Brake System DIAGNOSTICS

- Page 185 and 186:

4-5 [S100] SPECIFICATIONS AND SERVI

- Page 187 and 188:

4-5 [C1A2] COMPONENT PARTS 1. Pedal

- Page 189 and 190:

4-5 [W1A1] SERVICE PROCEDURE 1. Ped

- Page 191 and 192:

4-5 [W1A4] SERVICE PROCEDURE 1. Ped

- Page 193 and 194:

4-5 [W1C1] SERVICE PROCEDURE 1. Ped

- Page 195 and 196:

4-5 [W1F1] SERVICE PROCEDURE 1. Ped

- Page 197 and 198:

4-5 [W3A0] SERVICE PROCEDURE 3. Acc

- Page 199 and 200:

4-5 [K100] DIAGNOSTICS 1. Pedal Sys

- Page 201 and 202:

1. Heater Unit (1) Vent door (2) DE

- Page 203 and 204:

3. Control Unit (1) Temperature con

- Page 205 and 206:

3. Blower Motor Assembly A: REMOVAL

- Page 207 and 208:

4-7 [S100] SPECIFICATIONS 1. Specif

- Page 209 and 210:

4-7 [C200] COMPONENT PARTS 2. Intak

- Page 211 and 212:

4-7 [W1A0] SERVICE PROCEDURE 1. Saf

- Page 213 and 214:

4-7 [W300] SERVICE PROCEDURE 3. Too

- Page 215 and 216:

4-7 [W300] SERVICE PROCEDURE 3. Too

- Page 217 and 218:

4-7 [W4D0] SERVICE PROCEDURE 4. O-r

- Page 219 and 220:

4-7 [W600] SERVICE PROCEDURE 6. Dis

- Page 221 and 222:

4-7 [W7C0] SERVICE PROCEDURE 7. Eva

- Page 223 and 224:

4-7 [W8A0] SERVICE PROCEDURE 8. Lea

- Page 225 and 226:

4-7 [W8A7] SERVICE PROCEDURE 9. Lub

- Page 227 and 228:

4-7 [W11B0] SERVICE PROCEDURE 11. C

- Page 229 and 230:

4-7 [W11C0] SERVICE PROCEDURE 11. C

- Page 231 and 232:

4-7 [W13A0] SERVICE PROCEDURE 13. R

- Page 233 and 234:

4-7 [W15A0] SERVICE PROCEDURE 15. C

- Page 235 and 236:

4-7 [W17B0] SERVICE PROCEDURE 18. P

- Page 237 and 238:

4-7 [K200] DIAGNOSTICS 2. Performan

- Page 239 and 240:

4-7 [K200] DIAGNOSTICS 2. Performan

- Page 241 and 242:

4-7 [K400] DIAGNOSTICS 4. Compresso

- Page 243 and 244:

4-7 [K600] DIAGNOSTICS 6. Radiator

- Page 245 and 246:

4-7 [K800] DIAGNOSTICS 8. Condenser

- Page 247 and 248:

B: ELECTRICAL INSPECTION DIAGNOSTIC

- Page 249 and 250:

B4M1226B H4M1304A S4M0055A B4M2201C

- Page 251 and 252:

MEMO: DIAGNOSTICS 7 [T400] 4-4 4. S

- Page 253 and 254:

ABS sensor*2 (Wheel speed sensor) C

- Page 255 and 256:

6. Diagnostics Chart for On-board D

- Page 257 and 258:

Behavior of vehicle a) Directional

- Page 259 and 260:

1. CALLING UP A TROUBLE CODE 1) Tak

- Page 261 and 262:

MEMO: [T6D2] 4-4 DIAGNOSTICS 6. Dia

- Page 263 and 264:

7A1 : CHECK IF OTHER WARNING LIGHTS

- Page 265 and 266:

7A10 : CHECK POOR CONTACT IN CON- N

- Page 267 and 268:

7B1 : CHECK INSTALLATION OF ABSCM&H

- Page 269 and 270:

7B10 : CHECK WIRING HARNESS. Measur

- Page 271 and 272:

7C1 : CHECK DIAGNOSIS TERMINAL. Mea

- Page 273 and 274:

8. Diagnostics Chart with Trouble C

- Page 275 and 276:

8E1 : CHECK FRONT ABS SENSOR. 1) Tu

- Page 277 and 278:

DIAGNOSTICS 8E8 : CHECK BATTERY SHO

- Page 279 and 280:

DIAGNOSTICS 8E16 : CHECK GROUND SHO

- Page 281 and 282:

8I1 : CHECK INSTALLATION OF ABS SEN

- Page 283 and 284:

8I10 : CHECK RESISTANCE OF FRONT AB

- Page 285 and 286:

8I16 : CHECK GROUND SHORT OF HAR- N

- Page 287 and 288:

MEMO: DIAGNOSTICS [T8I23] 4-4 8. Di

- Page 289 and 290:

8J1 : CHECK IF THE WHEELS HAVE TURN

- Page 291 and 292:

MEMO: DIAGNOSTICS [T8J14] 4-4 8. Di

- Page 293 and 294:

8N1 : CHECK INPUT VOLTAGE OF ABSCM&

- Page 295 and 296:

8R1 : CHECK INPUT VOLTAGE OF ABSCM&

- Page 297 and 298:

8S1 : CHECK GROUND CIRCUIT OF ABSCM

- Page 299 and 300:

8T1 : CHECK GENERATOR. 1) Start eng

- Page 301 and 302:

MEMO: DIAGNOSTICS [T8T7] 4-4 8. Dia

- Page 303 and 304:

8U1 : CHECK SPECIFICATIONS OF THE A

- Page 305 and 306:

8U10 : CHECK ANY OTHER TROUBLE CODE

- Page 307 and 308:

8V1 : CHECK INPUT VOLTAGE OF ABSCM&

- Page 309 and 310:

MEMO: DIAGNOSTICS [T8V6] 4-4 8. Dia

- Page 311 and 312:

8W1 : CHECK INPUT VOLTAGE OF ABSCM&

- Page 313 and 314:

MEMO: DIAGNOSTICS [T8W8] 4-4 8. Dia

- Page 315 and 316:

8X1 : CHECK STOP LIGHTS COME ON. De

- Page 317 and 318:

8Y1 : CHECK ALL FOUR WHEELS FOR FRE

- Page 319 and 320:

DIAGNOSTICS 8Y8 : CHECK GROUND SHOR

- Page 321 and 322:

MEMO: DIAGNOSTICS [T8Y14] 4-4 8. Di

- Page 323 and 324:

6. FREEZE FRAME DATA NOTE: Data st

- Page 325 and 326:

B: LIST OF DIAGNOSTIC TROUBLE CODE

- Page 327 and 328:

10C1 : CHECK IGNITION SWITCH. : Is

- Page 329 and 330:

MEMO: DIAGNOSTICS 85 [T10C9] 4-4 10

- Page 331 and 332:

10D1 : CHECK WIRING HARNESS. 1) Tur

- Page 333 and 334:

MEMO: DIAGNOSTICS 89 [T10D6] 4-4 10

- Page 335 and 336:

WIRING DIAGRAM: DIAGNOSTICS 91 [T10

- Page 337 and 338:

10H7 : CHECK POOR CONTACT IN CON- N

- Page 339 and 340:

DIAGNOSTICS 10H16 : CHECK HARNESS/C

- Page 341 and 342:

10H23 : CHECK HUB RUNOUT. Measure h

- Page 343 and 344:

MEMO: DIAGNOSTICS 99 [T10H28] 4-4 1

- Page 345 and 346:

10L1 : CHECK OUTPUT OF ABS SENSOR U

- Page 347 and 348:

10L13 : CHECK ABS SENSOR SIGNAL. DI

- Page 349 and 350:

DIAGNOSTICS 10L21 : CHECK HARNESS/C

- Page 351 and 352:

10L28 : CHECK SHIELD CIRCUIT. DIAGN

- Page 353 and 354:

10M1 : CHECK IF THE WHEELS HAVE TUR

- Page 355 and 356:

MEMO: DIAGNOSTICS 111 [T10M14] 4-4

- Page 357 and 358:

10Q1 : CHECK INPUT VOLTAGE OF ABSCM

- Page 359 and 360:

10U1 : CHECK INPUT VOLTAGE OF ABSCM

- Page 361 and 362:

10V1 : CHECK GROUND CIRCUIT OF ABSC

- Page 363 and 364:

10W1 : CHECK GENERATOR. 1) Start en

- Page 365 and 366:

MEMO: DIAGNOSTICS 121 [T10W7] 4-4 1

- Page 367 and 368:

10X1 : CHECK GENERATOR. 1) Start en

- Page 369 and 370:

MEMO: DIAGNOSTICS 125 [T10X7] 4-4 1

- Page 371 and 372:

10Y1 : CHECK SPECIFICATIONS OF THE

- Page 373 and 374:

MEMO: DIAGNOSTICS 129 [T10Y8] 4-4 1

- Page 375 and 376:

DIAGNOSTICS 10Z1 : CHECK BATTERY SH

- Page 377 and 378:

MEMO: DIAGNOSTICS 133 [T10Z6] 4-4 1

- Page 379 and 380:

10AA1 : CHECK INPUT VOLTAGE OF ABSC

- Page 381 and 382:

10AB1 : CHECK VALVE RELAY IN ABSCM&

- Page 383 and 384:

10AC1 : CHECK INPUT VOLTAGE OF ABSC

- Page 385 and 386:

10AD1 : CHECK MOTOR RELAY IN ABSCM&

- Page 387 and 388:

10AE1 : CHECK INPUT VOLTAGE OF ABSC

- Page 389 and 390:

MEMO: DIAGNOSTICS 145 [T10AE8] 4-4

- Page 391 and 392:

10AF1 : CHECK OUTPUT OF STOP LIGHT

- Page 393 and 394:

MEMO: DIAGNOSTICS 149 [T10AF7] 4-4

- Page 395 and 396:

10AG1 : CHECK OUTPUT OF G SENSOR US

- Page 397 and 398:

10AG9 : CHECK G SENSOR. Measure vol

- Page 399 and 400:

10AH1 : CHECK OUTPUT OF G SENSOR US

- Page 401 and 402:

10AH15 : CHECK OPEN CIRCUIT IN G SE

- Page 403 and 404:

10AH21 : CHECK POOR CONTACT IN CONN

- Page 405 and 406:

10AI1 : CHECK OUTPUT OF G SENSOR US

- Page 407 and 408:

10AI10 : CHECK ABSCM&H/U. 1) Turn i

- Page 409 and 410:

10AJ1 : CHECK ALL FOUR WHEELS FOR F

- Page 411 and 412:

10AJ10 : CHECK G SENSOR. Measure vo

- Page 413 and 414:

B: CHECKING THE HYDRAULIC UNIT OPER