May 2003 ISSUE TONGBAI Page 4/5 COMPACT HYDRO in ...

May 2003 ISSUE TONGBAI Page 4/5 COMPACT HYDRO in ...

May 2003 ISSUE TONGBAI Page 4/5 COMPACT HYDRO in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

KAPRUN<br />

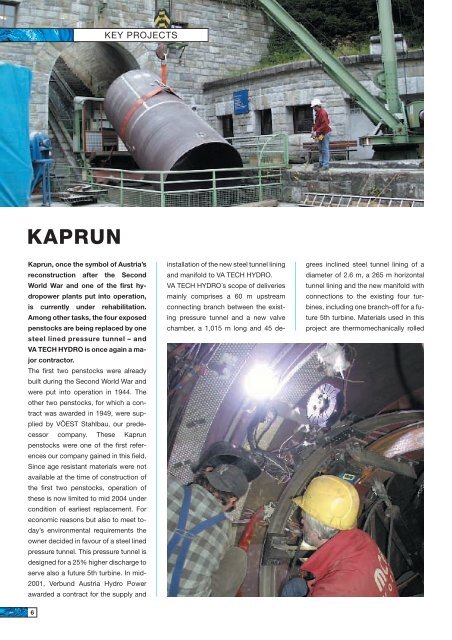

Kaprun, once the symbol of Austria’s<br />

reconstruction after the Second<br />

World War and one of the first hydropower<br />

plants put <strong>in</strong>to operation,<br />

is currently under rehabilitation.<br />

Among other tasks, the four exposed<br />

penstocks are be<strong>in</strong>g replaced by one<br />

steel l<strong>in</strong>ed pressure tunnel – and<br />

VA TECH <strong>HYDRO</strong> is once aga<strong>in</strong> a major<br />

contractor.<br />

The first two penstocks were already<br />

built dur<strong>in</strong>g the Second World War and<br />

were put <strong>in</strong>to operation <strong>in</strong> 1944. The<br />

other two penstocks, for which a contract<br />

was awarded <strong>in</strong> 1949, were supplied<br />

by VÖEST Stahlbau, our predecessor<br />

company. These Kaprun<br />

penstocks were one of the first references<br />

our company ga<strong>in</strong>ed <strong>in</strong> this field.<br />

S<strong>in</strong>ce age resistant materials were not<br />

available at the time of construction of<br />

the first two penstocks, operation of<br />

these is now limited to mid 2004 under<br />

condition of earliest replacement. For<br />

economic reasons but also to meet today’s<br />

environmental requirements the<br />

owner decided <strong>in</strong> favour of a steel l<strong>in</strong>ed<br />

pressure tunnel. This pressure tunnel is<br />

designed for a 25% higher discharge to<br />

serve also a future 5th turb<strong>in</strong>e. In mid-<br />

2001, Verbund Austria Hydro Power<br />

awarded a contract for the supply and<br />

6<br />

KEY PROJECTS<br />

<strong>in</strong>stallation of the new steel tunnel l<strong>in</strong><strong>in</strong>g<br />

and manifold to VA TECH <strong>HYDRO</strong>.<br />

VA TECH <strong>HYDRO</strong>´s scope of deliveries<br />

ma<strong>in</strong>ly comprises a 60 m upstream<br />

connect<strong>in</strong>g branch between the exist<strong>in</strong>g<br />

pressure tunnel and a new valve<br />

chamber, a 1,015 m long and 45 de-<br />

grees <strong>in</strong>cl<strong>in</strong>ed steel tunnel l<strong>in</strong><strong>in</strong>g of a<br />

diameter of 2.6 m, a 265 m horizontal<br />

tunnel l<strong>in</strong><strong>in</strong>g and the new manifold with<br />

connections to the exist<strong>in</strong>g four turb<strong>in</strong>es,<br />

<strong>in</strong>clud<strong>in</strong>g one branch-off for a future<br />

5th turb<strong>in</strong>e. Materials used <strong>in</strong> this<br />

project are thermomechanically rolled