May 2003 ISSUE TONGBAI Page 4/5 COMPACT HYDRO in ...

May 2003 ISSUE TONGBAI Page 4/5 COMPACT HYDRO in ...

May 2003 ISSUE TONGBAI Page 4/5 COMPACT HYDRO in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

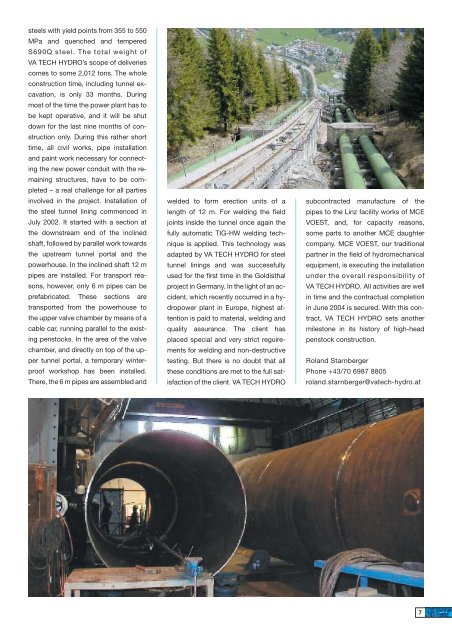

steels with yield po<strong>in</strong>ts from 355 to 550<br />

MPa and quenched and tempered<br />

S690Q steel. The total weight of<br />

VA TECH <strong>HYDRO</strong>’s scope of deliveries<br />

comes to some 2,012 tons. The whole<br />

construction time, <strong>in</strong>clud<strong>in</strong>g tunnel excavation,<br />

is only 33 months. Dur<strong>in</strong>g<br />

most of the time the power plant has to<br />

be kept operative, and it will be shut<br />

down for the last n<strong>in</strong>e months of construction<br />

only. Dur<strong>in</strong>g this rather short<br />

time, all civil works, pipe <strong>in</strong>stallation<br />

and pa<strong>in</strong>t work necessary for connect<strong>in</strong>g<br />

the new power conduit with the rema<strong>in</strong><strong>in</strong>g<br />

structures, have to be completed<br />

– a real challenge for all parties<br />

<strong>in</strong>volved <strong>in</strong> the project. Installation of<br />

the steel tunnel l<strong>in</strong><strong>in</strong>g commenced <strong>in</strong><br />

July 2002. It started with a section at<br />

the downstream end of the <strong>in</strong>cl<strong>in</strong>ed<br />

shaft, followed by parallel work towards<br />

the upstream tunnel portal and the<br />

powerhouse. In the <strong>in</strong>cl<strong>in</strong>ed shaft 12 m<br />

pipes are <strong>in</strong>stalled. For transport reasons,<br />

however, only 6 m pipes can be<br />

prefabricated. These sections are<br />

transported from the powerhouse to<br />

the upper valve chamber by means of a<br />

cable car, runn<strong>in</strong>g parallel to the exist<strong>in</strong>g<br />

penstocks. In the area of the valve<br />

chamber, and directly on top of the upper<br />

tunnel portal, a temporary w<strong>in</strong>terproof<br />

workshop has been <strong>in</strong>stalled.<br />

There, the 6 m pipes are assembled and<br />

welded to form erection units of a<br />

length of 12 m. For weld<strong>in</strong>g the field<br />

jo<strong>in</strong>ts <strong>in</strong>side the tunnel once aga<strong>in</strong> the<br />

fully automatic TIG-HW weld<strong>in</strong>g technique<br />

is applied. This technology was<br />

adapted by VA TECH <strong>HYDRO</strong> for steel<br />

tunnel l<strong>in</strong><strong>in</strong>gs and was successfully<br />

used for the first time <strong>in</strong> the Goldisthal<br />

project <strong>in</strong> Germany. In the light of an accident,<br />

which recently occurred <strong>in</strong> a hydropower<br />

plant <strong>in</strong> Europe, highest attention<br />

is paid to material, weld<strong>in</strong>g and<br />

quality assurance. The client has<br />

placed special and very strict reguirements<br />

for weld<strong>in</strong>g and non-destructive<br />

test<strong>in</strong>g. But there is no doubt that all<br />

these conditions are met to the full satisfaction<br />

of the client. VA TECH <strong>HYDRO</strong><br />

subcontracted manufacture of the<br />

pipes to the L<strong>in</strong>z facility works of MCE<br />

VOEST, and, for capacity reasons,<br />

some parts to another MCE daughter<br />

company. MCE VOEST, our traditional<br />

partner <strong>in</strong> the field of hydromechanical<br />

equipment, is execut<strong>in</strong>g the <strong>in</strong>stallation<br />

under the overall responsibility of<br />

VA TECH <strong>HYDRO</strong>. All activities are well<br />

<strong>in</strong> time and the contractual completion<br />

<strong>in</strong> June 2004 is secured. With this contract,<br />

VA TECH <strong>HYDRO</strong> sets another<br />

milestone <strong>in</strong> its history of high-head<br />

penstock construction.<br />

Roland Starnberger<br />

Phone +43/70 6987 8805<br />

roland.starnberger@vatech-hydro.at<br />

7