Characterization of the U.S. Industrial Commercial Boiler Population

Characterization of the U.S. Industrial Commercial Boiler Population

Characterization of the U.S. Industrial Commercial Boiler Population

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

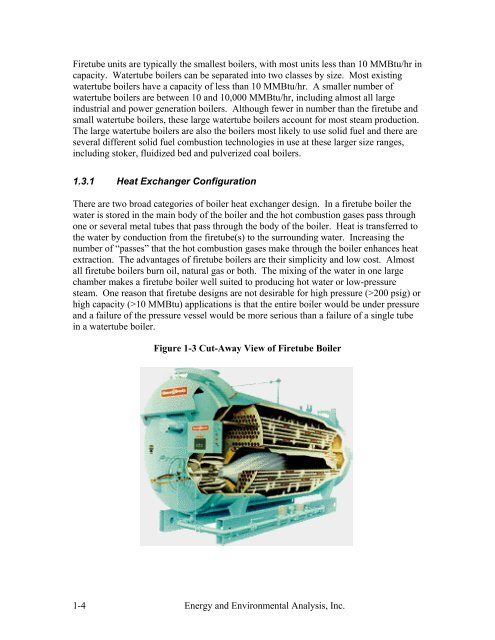

Firetube units are typically <strong>the</strong> smallest boilers, with most units less than 10 MMBtu/hr in<br />

capacity. Watertube boilers can be separated into two classes by size. Most existing<br />

watertube boilers have a capacity <strong>of</strong> less than 10 MMBtu/hr. A smaller number <strong>of</strong><br />

watertube boilers are between 10 and 10,000 MMBtu/hr, including almost all large<br />

industrial and power generation boilers. Although fewer in number than <strong>the</strong> firetube and<br />

small watertube boilers, <strong>the</strong>se large watertube boilers account for most steam production.<br />

The large watertube boilers are also <strong>the</strong> boilers most likely to use solid fuel and <strong>the</strong>re are<br />

several different solid fuel combustion technologies in use at <strong>the</strong>se larger size ranges,<br />

including stoker, fluidized bed and pulverized coal boilers.<br />

1.3.1 Heat Exchanger Configuration<br />

There are two broad categories <strong>of</strong> boiler heat exchanger design. In a firetube boiler <strong>the</strong><br />

water is stored in <strong>the</strong> main body <strong>of</strong> <strong>the</strong> boiler and <strong>the</strong> hot combustion gases pass through<br />

one or several metal tubes that pass through <strong>the</strong> body <strong>of</strong> <strong>the</strong> boiler. Heat is transferred to<br />

<strong>the</strong> water by conduction from <strong>the</strong> firetube(s) to <strong>the</strong> surrounding water. Increasing <strong>the</strong><br />

number <strong>of</strong> “passes” that <strong>the</strong> hot combustion gases make through <strong>the</strong> boiler enhances heat<br />

extraction. The advantages <strong>of</strong> firetube boilers are <strong>the</strong>ir simplicity and low cost. Almost<br />

all firetube boilers burn oil, natural gas or both. The mixing <strong>of</strong> <strong>the</strong> water in one large<br />

chamber makes a firetube boiler well suited to producing hot water or low-pressure<br />

steam. One reason that firetube designs are not desirable for high pressure (>200 psig) or<br />

high capacity (>10 MMBtu) applications is that <strong>the</strong> entire boiler would be under pressure<br />

and a failure <strong>of</strong> <strong>the</strong> pressure vessel would be more serious than a failure <strong>of</strong> a single tube<br />

in a watertube boiler.<br />

Figure 1-3 Cut-Away View <strong>of</strong> Firetube <strong>Boiler</strong><br />

1-4 Energy and Environmental Analysis, Inc.