Characterization of the U.S. Industrial Commercial Boiler Population

Characterization of the U.S. Industrial Commercial Boiler Population

Characterization of the U.S. Industrial Commercial Boiler Population

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

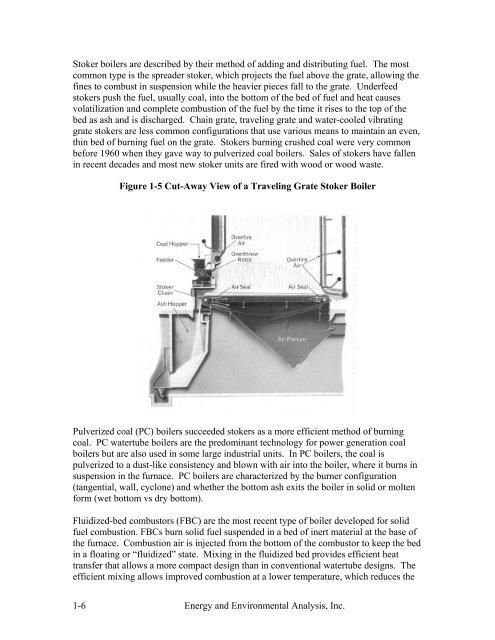

Stoker boilers are described by <strong>the</strong>ir method <strong>of</strong> adding and distributing fuel. The most<br />

common type is <strong>the</strong> spreader stoker, which projects <strong>the</strong> fuel above <strong>the</strong> grate, allowing <strong>the</strong><br />

fines to combust in suspension while <strong>the</strong> heavier pieces fall to <strong>the</strong> grate. Underfeed<br />

stokers push <strong>the</strong> fuel, usually coal, into <strong>the</strong> bottom <strong>of</strong> <strong>the</strong> bed <strong>of</strong> fuel and heat causes<br />

volatilization and complete combustion <strong>of</strong> <strong>the</strong> fuel by <strong>the</strong> time it rises to <strong>the</strong> top <strong>of</strong> <strong>the</strong><br />

bed as ash and is discharged. Chain grate, traveling grate and water-cooled vibrating<br />

grate stokers are less common configurations that use various means to maintain an even,<br />

thin bed <strong>of</strong> burning fuel on <strong>the</strong> grate. Stokers burning crushed coal were very common<br />

before 1960 when <strong>the</strong>y gave way to pulverized coal boilers. Sales <strong>of</strong> stokers have fallen<br />

in recent decades and most new stoker units are fired with wood or wood waste.<br />

Figure 1-5 Cut-Away View <strong>of</strong> a Traveling Grate Stoker <strong>Boiler</strong><br />

Pulverized coal (PC) boilers succeeded stokers as a more efficient method <strong>of</strong> burning<br />

coal. PC watertube boilers are <strong>the</strong> predominant technology for power generation coal<br />

boilers but are also used in some large industrial units. In PC boilers, <strong>the</strong> coal is<br />

pulverized to a dust-like consistency and blown with air into <strong>the</strong> boiler, where it burns in<br />

suspension in <strong>the</strong> furnace. PC boilers are characterized by <strong>the</strong> burner configuration<br />

(tangential, wall, cyclone) and whe<strong>the</strong>r <strong>the</strong> bottom ash exits <strong>the</strong> boiler in solid or molten<br />

form (wet bottom vs dry bottom).<br />

Fluidized-bed combustors (FBC) are <strong>the</strong> most recent type <strong>of</strong> boiler developed for solid<br />

fuel combustion. FBCs burn solid fuel suspended in a bed <strong>of</strong> inert material at <strong>the</strong> base <strong>of</strong><br />

<strong>the</strong> furnace. Combustion air is injected from <strong>the</strong> bottom <strong>of</strong> <strong>the</strong> combustor to keep <strong>the</strong> bed<br />

in a floating or “fluidized” state. Mixing in <strong>the</strong> fluidized bed provides efficient heat<br />

transfer that allows a more compact design than in conventional watertube designs. The<br />

efficient mixing allows improved combustion at a lower temperature, which reduces <strong>the</strong><br />

1-6 Energy and Environmental Analysis, Inc.