Characterization of the U.S. Industrial Commercial Boiler Population

Characterization of the U.S. Industrial Commercial Boiler Population

Characterization of the U.S. Industrial Commercial Boiler Population

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

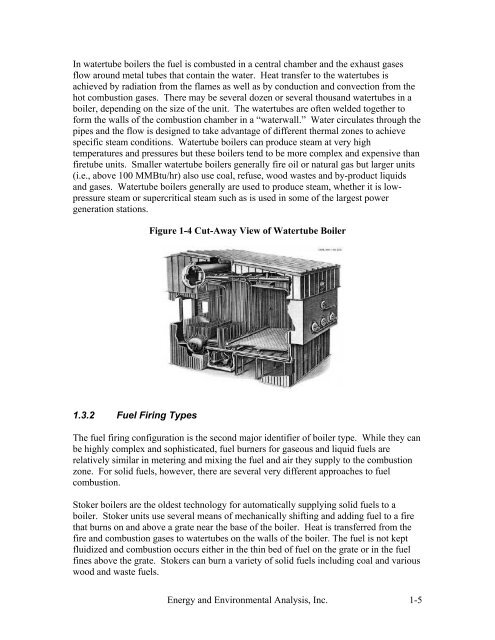

In watertube boilers <strong>the</strong> fuel is combusted in a central chamber and <strong>the</strong> exhaust gases<br />

flow around metal tubes that contain <strong>the</strong> water. Heat transfer to <strong>the</strong> watertubes is<br />

achieved by radiation from <strong>the</strong> flames as well as by conduction and convection from <strong>the</strong><br />

hot combustion gases. There may be several dozen or several thousand watertubes in a<br />

boiler, depending on <strong>the</strong> size <strong>of</strong> <strong>the</strong> unit. The watertubes are <strong>of</strong>ten welded toge<strong>the</strong>r to<br />

form <strong>the</strong> walls <strong>of</strong> <strong>the</strong> combustion chamber in a “waterwall.” Water circulates through <strong>the</strong><br />

pipes and <strong>the</strong> flow is designed to take advantage <strong>of</strong> different <strong>the</strong>rmal zones to achieve<br />

specific steam conditions. Watertube boilers can produce steam at very high<br />

temperatures and pressures but <strong>the</strong>se boilers tend to be more complex and expensive than<br />

firetube units. Smaller watertube boilers generally fire oil or natural gas but larger units<br />

(i.e., above 100 MMBtu/hr) also use coal, refuse, wood wastes and by-product liquids<br />

and gases. Watertube boilers generally are used to produce steam, whe<strong>the</strong>r it is lowpressure<br />

steam or supercritical steam such as is used in some <strong>of</strong> <strong>the</strong> largest power<br />

generation stations.<br />

1.3.2 Fuel Firing Types<br />

Figure 1-4 Cut-Away View <strong>of</strong> Watertube <strong>Boiler</strong><br />

The fuel firing configuration is <strong>the</strong> second major identifier <strong>of</strong> boiler type. While <strong>the</strong>y can<br />

be highly complex and sophisticated, fuel burners for gaseous and liquid fuels are<br />

relatively similar in metering and mixing <strong>the</strong> fuel and air <strong>the</strong>y supply to <strong>the</strong> combustion<br />

zone. For solid fuels, however, <strong>the</strong>re are several very different approaches to fuel<br />

combustion.<br />

Stoker boilers are <strong>the</strong> oldest technology for automatically supplying solid fuels to a<br />

boiler. Stoker units use several means <strong>of</strong> mechanically shifting and adding fuel to a fire<br />

that burns on and above a grate near <strong>the</strong> base <strong>of</strong> <strong>the</strong> boiler. Heat is transferred from <strong>the</strong><br />

fire and combustion gases to watertubes on <strong>the</strong> walls <strong>of</strong> <strong>the</strong> boiler. The fuel is not kept<br />

fluidized and combustion occurs ei<strong>the</strong>r in <strong>the</strong> thin bed <strong>of</strong> fuel on <strong>the</strong> grate or in <strong>the</strong> fuel<br />

fines above <strong>the</strong> grate. Stokers can burn a variety <strong>of</strong> solid fuels including coal and various<br />

wood and waste fuels.<br />

Energy and Environmental Analysis, Inc. 1-5