AP-G84/04 Best practice in road use data collection, analysis ... - WIM

AP-G84/04 Best practice in road use data collection, analysis ... - WIM

AP-G84/04 Best practice in road use data collection, analysis ... - WIM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Accessed by AR - ARRB TRANSPORT RESEARCH on <strong>04</strong> Feb 2005<br />

Aust<strong>road</strong>s 20<strong>04</strong><br />

— 4 —<br />

<strong>Best</strong> Practices <strong>in</strong> Road Use Data Collection, Analysis and Report<strong>in</strong>g<br />

With the prevalent <strong>use</strong> of s<strong>in</strong>gle axle sensor for traffic counts, it is important that the number of axle<br />

pairs obta<strong>in</strong>ed be corrected for vehicles with more than two axles. The correction factor is<br />

dependent on traffic composition and site conditions and should be calibrated on-site. Some<br />

guidel<strong>in</strong>es on the correction factor are given <strong>in</strong> GTEP Part 3. For example, if heavy vehicles<br />

account for 12% of the total traffic on an urban highway, the number of axle-pairs obta<strong>in</strong>ed should<br />

be reduced by about 6%, i.e. the correction factor is 0.94 ±0.15 at the 95 % confidence limits.<br />

There are no standard <strong>practice</strong>s amongst RAs regard<strong>in</strong>g when axle pair counts are collected rather<br />

than classified counts. At the Aust<strong>road</strong>s Road Use Data Workshop, there was general agreement<br />

that classified counts be collected wherever possible. As mentioned earlier, a pair of axle sensors<br />

is essential for classified counts <strong>in</strong> spite of higher <strong>in</strong>stallation and ma<strong>in</strong>tenance costs. An axle<br />

sensor pair is also more appropriate than a s<strong>in</strong>gle axle sensor <strong>in</strong> obta<strong>in</strong><strong>in</strong>g bi-directional counts as<br />

traffic volume <strong>in</strong>creases.<br />

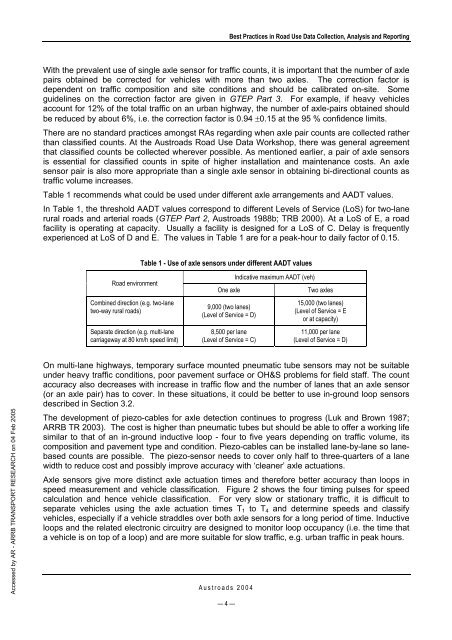

Table 1 recommends what could be <strong>use</strong>d under different axle arrangements and AADT values.<br />

In Table 1, the threshold AADT values correspond to different Levels of Service (LoS) for two-lane<br />

rural <strong>road</strong>s and arterial <strong>road</strong>s (GTEP Part 2, Aust<strong>road</strong>s 1988b; TRB 2000). At a LoS of E, a <strong>road</strong><br />

facility is operat<strong>in</strong>g at capacity. Usually a facility is designed for a LoS of C. Delay is frequently<br />

experienced at LoS of D and E. The values <strong>in</strong> Table 1 are for a peak-hour to daily factor of 0.15.<br />

Road environment<br />

Comb<strong>in</strong>ed direction (e.g. two-lane<br />

two-way rural <strong>road</strong>s)<br />

Separate direction (e.g. multi-lane<br />

carriageway at 80 km/h speed limit)<br />

Table 1 - Use of axle sensors under different AADT values<br />

Indicative maximum AADT (veh)<br />

One axle Two axles<br />

9,000 (two lanes)<br />

(Level of Service = D)<br />

8,500 per lane<br />

(Level of Service = C)<br />

15,000 (two lanes)<br />

(Level of Service = E<br />

or at capacity)<br />

11,000 per lane<br />

(Level of Service = D)<br />

On multi-lane highways, temporary surface mounted pneumatic tube sensors may not be suitable<br />

under heavy traffic conditions, poor pavement surface or OH&S problems for field staff. The count<br />

accuracy also decreases with <strong>in</strong>crease <strong>in</strong> traffic flow and the number of lanes that an axle sensor<br />

(or an axle pair) has to cover. In these situations, it could be better to <strong>use</strong> <strong>in</strong>-ground loop sensors<br />

described <strong>in</strong> Section 3.2.<br />

The development of piezo-cables for axle detection cont<strong>in</strong>ues to progress (Luk and Brown 1987;<br />

ARRB TR 2003). The cost is higher than pneumatic tubes but should be able to offer a work<strong>in</strong>g life<br />

similar to that of an <strong>in</strong>-ground <strong>in</strong>ductive loop - four to five years depend<strong>in</strong>g on traffic volume, its<br />

composition and pavement type and condition. Piezo-cables can be <strong>in</strong>stalled lane-by-lane so lanebased<br />

counts are possible. The piezo-sensor needs to cover only half to three-quarters of a lane<br />

width to reduce cost and possibly improve accuracy with ‘cleaner’ axle actuations.<br />

Axle sensors give more dist<strong>in</strong>ct axle actuation times and therefore better accuracy than loops <strong>in</strong><br />

speed measurement and vehicle classification. Figure 2 shows the four tim<strong>in</strong>g pulses for speed<br />

calculation and hence vehicle classification. For very slow or stationary traffic, it is difficult to<br />

separate vehicles us<strong>in</strong>g the axle actuation times T1 to T4 and determ<strong>in</strong>e speeds and classify<br />

vehicles, especially if a vehicle straddles over both axle sensors for a long period of time. Inductive<br />

loops and the related electronic circuitry are designed to monitor loop occupancy (i.e. the time that<br />

a vehicle is on top of a loop) and are more suitable for slow traffic, e.g. urban traffic <strong>in</strong> peak hours.