Untitled - Eurocopter

Untitled - Eurocopter

Untitled - Eurocopter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Data<br />

No Hot Section Inspection (HSI) is scheduled and, if necessary, component replacement will be on an<br />

on-condition basis.<br />

The maintenance plan for the PW206B2 engine incorporates the following features:<br />

The minimization of scheduled maintenance in accordance with MSG-III style analysis.<br />

Helicopter Engine Condition and Trend Monitoring (HECTM®) used to determine the economical<br />

threshold to perform refurbishment.<br />

Repair development will continue during service of the PW200 engine with the objective of expanding<br />

on repair schemes currently contained in both the Maintenance Manual and Overhaul Manual. This will<br />

keep engine maintenance costs, aircraft downtime, spare engine inventories and total operating costs<br />

to a minimum.<br />

Accessories Time Between Overhaul<br />

Engine accessories are monitored, as defined by the Illustrated Parts Catalog, with a removal threshold<br />

that is based on the operator's experience, with the following exception: TBO recommendation for the<br />

Fuel Management Module (FMM) is engine TBO plus 500 hours.<br />

Periodic Inspection - Tolerances<br />

Unless otherwise stated, the tolerance for periodic or scheduled inspections are as follows:<br />

• Hourly Interval tolerance: Ten percent (10%), or up to a maximum of 100 hours operating time,<br />

whichever is less.<br />

• Calendar Interval tolerance: Ten percent (10%), or up to a maximum of 30 days calendar time,<br />

whichever is less.<br />

NOTE:The tolerance is established for maintenance scheduling convenience only and must be approved<br />

by the governing civil aviation authority. Subsequent intervals will be adjusted to re-establish the<br />

original schedule. When an inspection is done more than 10% early, subsequent inspections will be<br />

advanced as required so as to not exceed the maximum tolerance. Concurrence and final approval of<br />

the inspection interval tolerance by the governing civil aviation authority is the responsibility of the owner/operator.<br />

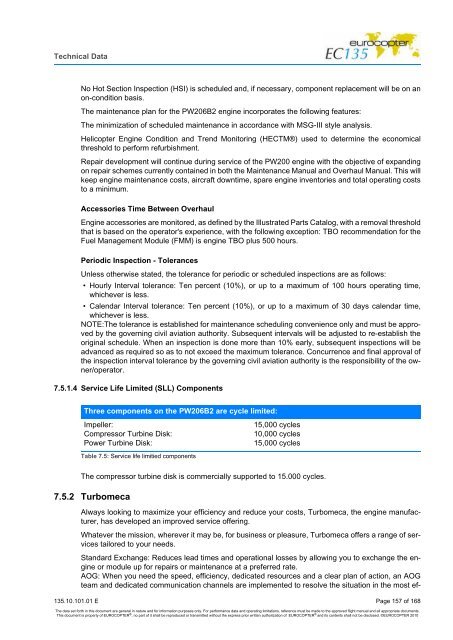

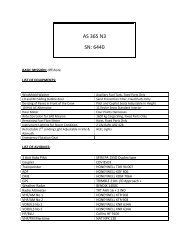

7.5.1.4 Service Life Limited (SLL) Components<br />

Three components on the PW206B2 are cycle limited:<br />

Impeller:<br />

Compressor Turbine Disk:<br />

Power Turbine Disk:<br />

Table 7.5: Service life limitied components<br />

The compressor turbine disk is commercially supported to 15.000 cycles.<br />

7.5.2 Turbomeca<br />

15,000 cycles<br />

10,000 cycles<br />

15,000 cycles<br />

Always looking to maximize your efficiency and reduce your costs, Turbomeca, the engine manufacturer,<br />

has developed an improved service offering.<br />

Whatever the mission, wherever it may be, for business or pleasure, Turbomeca offers a range of services<br />

tailored to your needs.<br />

Standard Exchange: Reduces lead times and operational losses by allowing you to exchange the engine<br />

or module up for repairs or maintenance at a preferred rate.<br />

AOG: When you need the speed, efficiency, dedicated resources and a clear plan of action, an AOG<br />

team and dedicated communication channels are implemented to resolve the situation in the most ef-<br />

135.10.101.01 E Page 157 of 168<br />

The data set forth in this document are general in nature and for information purposes only. For performance data and operating limitations, reference must be made to the approved flight manual and all appropriate documents.<br />

This document is property of EUROCOPTER ® , no part of it shall be reproduced or transmitted without the express prior written authorization of EUROCOPTER ® and its contents shall not be disclosed. ©EUROCOPTER 2010