EIS-0113_Section_11 - Hanford Site

EIS-0113_Section_11 - Hanford Site

EIS-0113_Section_11 - Hanford Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

¢ {k<br />

6 0<br />

Adi 2<br />

24N<br />

-19- -30-<br />

3.1.8.9<br />

For instance, a ¢ F ill of --ml Cbounded gallons n£ highly —di ... I've<br />

This may explain why the WE is so reluctant to remove the `single-<br />

sludge each slurry the all well floor of a vitrification plant could Mve<br />

ebe<strong>11</strong>` tank waatee at ...lend. But this ch..Fe not he cons leered an envi[on-<br />

a mgni£icant impact be ¢ubaequent operation and—let enanre of the plant.<br />

pally acceptable rationale for their permanent in-place disposal.<br />

One impact of this and other. spills 18 to make the processing areas very<br />

QA<br />

V<br />

radioactive. This would make entry into the process aremuch more dangerous.<br />

sequentially, all maintenance, repair and replacement requiring entry<br />

by personnel would involve higher exposures and work under more hazardous<br />

conditions. This could seriously impair the maintainability and bent. she<br />

operability of the plant.<br />

There is another class of events that could seriously affect operation<br />

of a vitrification plant that EOE/E15 -0013 has not taken into account. This<br />

relates to the Ability to produce consistently the kind of feed solution.<br />

and slurries that will . r woad far vitrification, without ¢.. 2.mly<br />

imoairinc the integrity of the 'Tank Farm' operation.<br />

For instance, water and but chemicals will be Added to the sludge and<br />

the mixture is then agitated to produce a slurry-Feed for the glass matter.<br />

As noted, each a process has been suspected at S.p to cause failures of<br />

meveral task cooling coils o As laa.t one mcceaion. Failure of a large<br />

numbee of booting coil. in the new tanks weld seriously impair their<br />

ability to held high-level wastes. The alder tank. already have oany<br />

leaking coil¢, rendering them unfit for holding hot sludge. Most of the<br />

older task¢ also have leaks in the primary c t vock.l. which are<br />

currently plugged with salt which has crystellizad on the cracks. Thus<br />

the transfer of wn9se free older tanks to Never ones and the preparation<br />

of feedstock for the vitrification. plant could lead to serious problems,<br />

including leaks of—dicactivit, and impairment of the `Tank Fars" o{rerations<br />

Grouting<br />

In order for WE to implement its long-term defense waste management<br />

plan of presently disposing of was ¢ groiomly Oaeignamd as `high-level•<br />

in ahellow Initialpits, it Aad Co adopt a Mw, waste management standard,<br />

diet w ¢ tailored to set this particular policy decision. Thus, .<br />

promulgated W. Order 5830 which m,numdee the previous standard. 1.<br />

..unl Ehapter 05<strong>11</strong>1 at in 1973. Although this standard he. ben justified<br />

as being Named oa the 'beet .—liable bi gg er,- it he.. not been subject to<br />

independent evaluation. Nor has the underlying scientific rationale base<br />

..jest to an span peer re i.w. Moreover. this raw. standard is certainly<br />

not based on scientific data derived free operating experience of DOE nuclear<br />

wait. programs. Nor am they established to beet. the 35 millirem/year<br />

radiation dose standard set for commercial Nuclear power plants, but rather<br />

M the 500 millirem/year limit.<br />

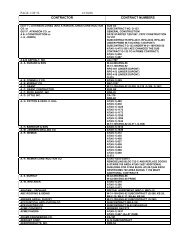

Without question, WE Order 5830 will allow for aig.ifi ..t increases<br />

in the radiological and ..In burden of soil. at WE site.. Grouting of<br />

nuclear and toxic wastes for .oil disposal will he A major contributor. In<br />

ibis regard, ApFendix 0 0£ the —at IS i. seriously a.fisi.st in presenting<br />

data shows volso.s, a .bone of radioactive and non-radioactive waste.<br />

vn the grout and leach rates. on page D.S, con£1i<strong>11</strong>no figures are given<br />

an to the grouted waste volumes.<br />

3.1.8.1<br />

RECEIVED DOE-RL<br />

SEP 16 1986 62•<br />

WM DIVISION<br />

On the average to la he bout five grout<br />

ampaign. per year, each lasting ato m1 mono. RECEIVED DDE-'° '<br />

xhnut 1,800 m3 of waste feed -old be mixed with<br />

SEP 1 610 pulz<br />

WM DIVISION