Pro 501st Airless Paint Sprayer - Graco Inc.

Pro 501st Airless Paint Sprayer - Graco Inc.

Pro 501st Airless Paint Sprayer - Graco Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

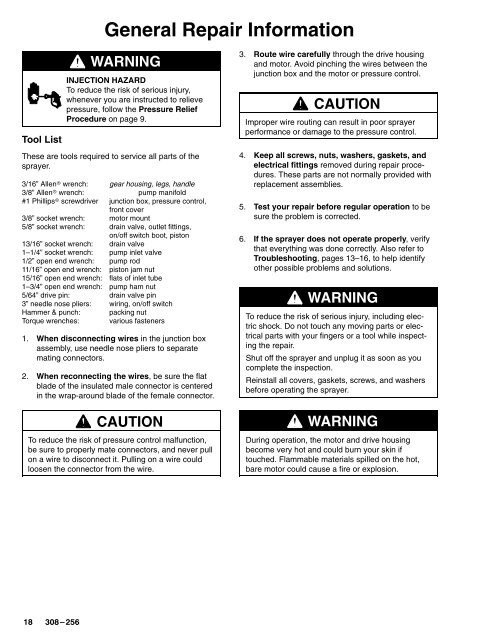

General Repair Information<br />

Tool List<br />

WARNING<br />

INJECTION HAZARD<br />

To reduce the risk of serious injury,<br />

whenever you are instructed to relieve<br />

pressure, follow the Pressure Relief<br />

<strong>Pro</strong>cedure on page 9.<br />

These are tools required to service all parts of the<br />

sprayer.<br />

3/16” Allen wrench: gear housing, legs, handle<br />

3/8” Allen wrench: pump manifold<br />

#1 Phillips screwdriver junction box, pressure control,<br />

front cover<br />

3/8” socket wrench: motor mount<br />

5/8” socket wrench: drain valve, outlet fittings,<br />

on/off switch boot, piston<br />

13/16” socket wrench: drain valve<br />

1–1/4” socket wrench: pump inlet valve<br />

1/2” open end wrench: pump rod<br />

11/16” open end wrench: piston jam nut<br />

15/16” open end wrench: flats of inlet tube<br />

1–3/4” open end wrench: pump ham nut<br />

5/64” drive pin: drain valve pin<br />

3” needle nose pliers: wiring, on/off switch<br />

Hammer & punch: packing nut<br />

Torque wrenches: various fasteners<br />

1. When disconnecting wires in the junction box<br />

assembly, use needle nose pliers to separate<br />

mating connectors.<br />

2. When reconnecting the wires, be sure the flat<br />

blade of the insulated male connector is centered<br />

in the wrap-around blade of the female connector.<br />

CAUTION<br />

To reduce the risk of pressure control malfunction,<br />

be sure to properly mate connectors, and never pull<br />

on a wire to disconnect it. Pulling on a wire could<br />

loosen the connector from the wire.<br />

3. Route wire carefully through the drive housing<br />

and motor. Avoid pinching the wires between the<br />

junction box and the motor or pressure control.<br />

CAUTION<br />

Improper wire routing can result in poor sprayer<br />

performance or damage to the pressure control.<br />

4. Keep all screws, nuts, washers, gaskets, and<br />

electrical fittings removed during repair procedures.<br />

These parts are not normally provided with<br />

replacement assemblies.<br />

5. Test your repair before regular operation to be<br />

sure the problem is corrected.<br />

6. If the sprayer does not operate properly, verify<br />

that everything was done correctly. Also refer to<br />

Troubleshooting, pages 13–16, to help identify<br />

other possible problems and solutions.<br />

WARNING<br />

To reduce the risk of serious injury, including electric<br />

shock. Do not touch any moving parts or electrical<br />

parts with your fingers or a tool while inspecting<br />

the repair.<br />

Shut off the sprayer and unplug it as soon as you<br />

complete the inspection.<br />

Reinstall all covers, gaskets, screws, and washers<br />

before operating the sprayer.<br />

WARNING<br />

During operation, the motor and drive housing<br />

become very hot and could burn your skin if<br />

touched. Flammable materials spilled on the hot,<br />

bare motor could cause a fire or explosion.