PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

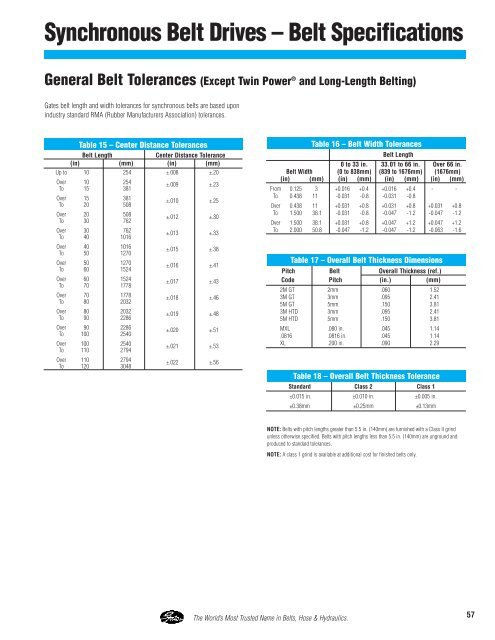

Synchronous <strong>Belt</strong> <strong>Drives</strong> – <strong>Belt</strong> Specifications<br />

General <strong>Belt</strong> Tolerances (Except Twin Power ® and Long-Length <strong>Belt</strong>ing)<br />

Gates belt length and width tolerances for synchronous belts are based upon<br />

industry standard RMA (Rubber Manufacturers Association) tolerances.<br />

Table 15 – Center Distance Tolerances<br />

<strong>Belt</strong> Length<br />

Center Distance Tolerance<br />

(in) (mm) (in) (mm)<br />

Up to 10 254 ±.008 ±.20<br />

Over 10 254<br />

To 15 381<br />

±.009 ±.23<br />

Over 15 381<br />

To 20 508<br />

±.010 ±.25<br />

Over 20 508<br />

To 30 762<br />

±.012 ±.30<br />

Over 30 762<br />

To 40 1016<br />

±.013 ±.33<br />

Over 40 1016<br />

To 50 1270<br />

±.015 ±.38<br />

Over 50 1270<br />

To 60 1524<br />

±.016 ±.41<br />

Over 60 1524<br />

To 70 1778<br />

±.017 ±.43<br />

Over 70 1778<br />

To 80 2032<br />

±.018 ±.46<br />

Over 80 2032<br />

To 90 2286<br />

±.019 ±.48<br />

Over 90 2286<br />

To 100 2540<br />

±.020 ±.51<br />

Over 100 2540<br />

To 110 2794<br />

±.021 ±.53<br />

Over 110 2794<br />

To 120 3048<br />

±.022 ±.56<br />

Table 16 – <strong>Belt</strong> Width Tolerances<br />

<strong>Belt</strong> Length<br />

0 to 33 in. 33.01 to 66 in. Over 66 in.<br />

<strong>Belt</strong> Width (0 to 838mm) (839 to 1676mm) (1676mm)<br />

(in) (mm) (in) (mm) (in) (mm) (in) (mm)<br />

From 0.125 3 +0.016 +0.4 +0.016 +0.4 - -<br />

To 0.438 11 -0.031 -0.8 -0.031 -0.8<br />

Over 0.438 11 +0.031 +0.8 +0.031 +0.8 +0.031 +0.8<br />

To 1.500 38.1 -0.031 -0.8 -0.047 -1.2 -0.047 -1.2<br />

Over 1.500 38.1 +0.031 +0.8 +0.047 +1.2 +0.047 +1.2<br />

To 2.000 50.8 -0.047 -1.2 -0.047 -1.2 -0.063 -1.6<br />

Table 17 – Overall <strong>Belt</strong> Thickness Dimensions<br />

Pitch <strong>Belt</strong> Overall Thickness (ref.)<br />

Code Pitch (in.) (mm)<br />

2M GT 2mm .060 1.52<br />

3M GT 3mm .095 2.41<br />

5M GT 5mm .150 3.81<br />

3M HTD 3mm .095 2.41<br />

5M HTD 5mm .150 3.81<br />

MXL .080 in. .045 1.14<br />

.0816 .0816 in. .045 1.14<br />

XL .200 in. .090 2.29<br />

Table 18 – Overall <strong>Belt</strong> Thickness Tolerance<br />

Standard Class 2 Class 1<br />

±0.015 in. ±0.010 in. ±0.005 in.<br />

±0.38mm ±0.25mm ±0.13mm<br />

NOTE: <strong>Belt</strong>s with pitch lengths greater than 5.5 in. (140mm) are furnished with a Class II grind<br />

unless otherwise specified. <strong>Belt</strong>s with pitch lengths less than 5.5 in. (140mm) are unground and<br />

produced to standard tolerances.<br />

NOTE: A class 1 grind is available at additional cost for finished belts only.<br />

The World’s Most Trusted Name in <strong>Belt</strong>s, Hose & Hydraulics.<br />

57