PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Polyflex ® JB ® <strong>Belt</strong> <strong>Drives</strong><br />

Advantages of<br />

Joined Construction<br />

The actual size of a Polyflex JB belt is relatively<br />

small when compared to a conventional V-belt.<br />

Small belts, just by their nature, have a slightly<br />

lower torsional and lateral rigidity. Subsequently,<br />

there is a possibility of turning over (Fig. 17) when<br />

subjected to a misalignment, power surge or<br />

vibrations at or near its natural frequency. To prevent<br />

such stability problems, the belt is constructed with<br />

the overcord connected or “joined” together as<br />

shown in Fig. 18. Joining the strands limits the<br />

possibility of a belt turning over on properly<br />

maintained drives when subjected to various types<br />

of load fluctuations and vibrations. The ribbed<br />

overcord of the belt also helps increase torsional<br />

and lateral rigidity and increases belt flexibility.<br />

Figure 17 — Turned Over <strong>Belt</strong><br />

Figure 18 – Polyflex JB<br />

Polyflex JB belts are manufactured with either two<br />

or three belt strands joined together. Any<br />

combination of Polyflex JB belts can be used on a<br />

single drive in matched sets. For example, if six<br />

belts are needed to transmit a load, matched sets of<br />

two joined belts with three strands in each belt<br />

would work as well as matched sets of three belts<br />

with two strands in each belt (see Fig. 19).<br />

Figure 19<br />

Matched Sets<br />

When more than one Gates Polyflex JB <strong>Belt</strong> (more<br />

than 3 strands, see Joined Construction) is required<br />

on a drive, matched sets of belts must be used. A<br />

matched set of Polyflex JB belts is factory measured<br />

and tied together. The belts are measured and<br />

grouped within various length ranges. On multiple<br />

belt drives (more than 3 strands) this assures that<br />

each belt shares its proportion of the load being<br />

transmitted. Contact Gates Customer Service for<br />

availability.<br />

Standard Polyflex JB<br />

<strong>Belt</strong> Lengths<br />

Below in table 26 are the standard belt lengths, with<br />

each belt length available in both two and three<br />

strands.<br />

Standard Sheave<br />

Diameters<br />

Gates specifies standard sheave diameters to help<br />

design a Polyflex JB drive. Listed below in table 27<br />

are the standard sheave diameters. Contact Gates<br />

Customer Service for availability.<br />

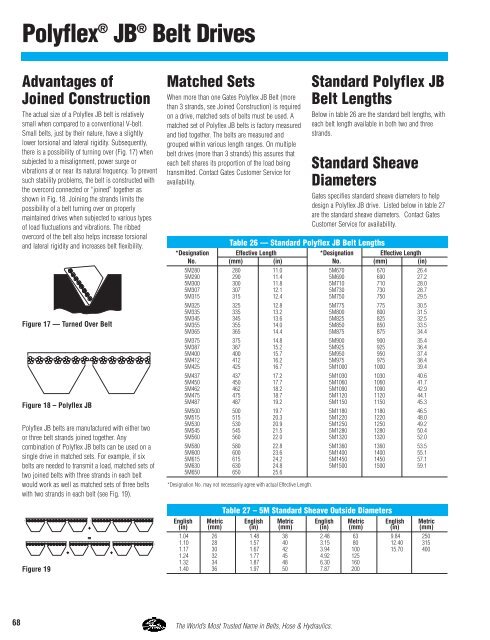

Table 26 — Standard Polyflex JB <strong>Belt</strong> Lengths<br />

*Designation Effective Length<br />

*Designation Effective Length<br />

No. (mm) (in)<br />

No. (mm) (in)<br />

5M280 280 11.0<br />

5M670 670 26.4<br />

5M290 290 11.4<br />

5M690 690 27.2<br />

5M300 300 11.8<br />

5M710 710 28.0<br />

5M307 307 12.1<br />

5M730 730 28.7<br />

5M315 315 12.4<br />

5M750 750 29.5<br />

5M325 325 12.8<br />

5M775 775 30.5<br />

5M335 335 13.2<br />

5M800 800 31.5<br />

5M345 345 13.6<br />

5M825 825 32.5<br />

5M355 355 14.0<br />

5M850 850 33.5<br />

5M365 365 14.4<br />

5M875 875 34.4<br />

5M375 375 14.8<br />

5M900 900 35.4<br />

5M387 387 15.2<br />

5M925 925 36.4<br />

5M400 400 15.7<br />

5M950 950 37.4<br />

5M412 412 16.2<br />

5M975 975 38.4<br />

5M425 425 16.7<br />

5M1000 1000 39.4<br />

5M437 437 17.2<br />

5M1030 1030 40.6<br />

5M450 450 17.7<br />

5M1060 1060 41.7<br />

5M462 462 18.2<br />

5M1090 1090 42.9<br />

5M475 475 18.7<br />

5M1120 1120 44.1<br />

5M487 487 19.2<br />

5M1150 1150 45.3<br />

5M500 500 19.7<br />

5M1180 1180 46.5<br />

5M515 515 20.3<br />

5M1220 1220 48.0<br />

5M530 530 20.9<br />

5M1250 1250 49.2<br />

5M545 545 21.5<br />

5M1280 1280 50.4<br />

5M560 560 22.0<br />

5M1320 1320 52.0<br />

5M580 580 22.8<br />

5M1360 1360 53.5<br />

5M600 600 23.6<br />

5M1400 1400 55.1<br />

5M615 615 24.2<br />

5M1450 1450 57.1<br />

5M630 630 24.8<br />

5M1500 1500 59.1<br />

5M650 650 25.6<br />

*Designation No. may not necessarily agree with actual Effective Length.<br />

Table 27 – 5M Standard Sheave Outside Diameters<br />

English<br />

(in)<br />

Metric<br />

(mm)<br />

English<br />

(in)<br />

Metric<br />

(mm)<br />

English<br />

(in)<br />

Metric<br />

(mm)<br />

English<br />

(in)<br />

Metric<br />

(mm)<br />

1.04 26<br />

1.48 38<br />

2.48 63<br />

9.84 250<br />

1.10 28<br />

1.57 40<br />

3.15 80<br />

12.40 315<br />

1.17 30<br />

1.67 42<br />

3.94 100<br />

15.70 400<br />

1.24 32<br />

1.77 45<br />

4.92 125<br />

1.32 34<br />

1.87 48<br />

6.30 160<br />

1.40 36<br />

1.97 50<br />

7.87 200<br />

68 The World’s Most Trusted Name in <strong>Belt</strong>s, Hose & Hydraulics.