PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Polyflex ® JB ® and Micro-V ® <strong>Belt</strong>s – Engineering<br />

V. Installation and<br />

Takeup Allowances<br />

Like any power transmission belt drive, installation<br />

allowance is necessary for Polyflex JB and Micro-V<br />

drives to assure the belt can be installed without<br />

damage and then tensioned correctly. The standard<br />

installation allowance is the minimum decrease in<br />

center distance required to install the belt on the<br />

sheaves (See Fig. 25).<br />

NOTE: A belt should never be rolled onto a<br />

sheave. This can damage tensile cords in the belt<br />

resulting in premature failure. The damage may be<br />

invisible and difficult to identify as the cause of<br />

failure. A rolled on belt, because of cord damage,<br />

may also elongate rapidly and run out of takeup.<br />

Figure 25 – Installation and Takeup<br />

Takeup allowance is the increase in center distance<br />

which permits retensioning the belt due to wear and<br />

elongation. Takeup values lower than standard<br />

practice may not permit full belt life and could be a<br />

cause for excessive slipping.<br />

Installation and takeup allowances are listed in<br />

Tables 40 and 41.<br />

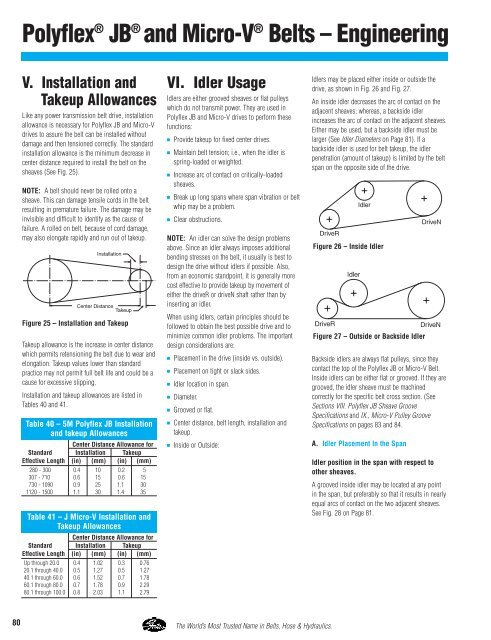

Table 40 – 5M Polyflex JB Installation<br />

and takeup Allowances<br />

Center Distance Allowance for<br />

Standard Installation Takeup<br />

Effective Length (in) (mm) (in) (mm)<br />

280 - 300 0.4 10 0.2 5<br />

307 - 710 0.6 15 0.6 15<br />

730 - 1090 0.9 25 1.1 30<br />

1120 - 1500 1.1 30 1.4 35<br />

Table 41 – J Micro-V Installation and<br />

Takeup Allowances<br />

Center Distance Allowance for<br />

Standard Installation Takeup<br />

Effective Length (in) (mm) (in) (mm)<br />

Up through 20.0 0.4 1.02 0.3 0.76<br />

20.1 through 40.0 0.5 1.27 0.5 1.27<br />

40.1 through 60.0 0.6 1.52 0.7 1.78<br />

60.1 through 80.0 0.7 1.78 0.9 2.29<br />

80.1 through 100.0 0.8 2.03 1.1 2.79<br />

VI. Idler Usage<br />

Idlers are either grooved sheaves or flat pulleys<br />

which do not transmit power. They are used in<br />

Polyflex JB and Micro-V drives to perform these<br />

functions:<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Provide takeup for fixed center drives.<br />

Maintain belt tension; i.e., when the idler is<br />

spring-loaded or weighted.<br />

Increase arc of contact on critically-loaded<br />

sheaves.<br />

Break up long spans where span vibration or belt<br />

whip may be a problem.<br />

Clear obstructions.<br />

NOTE: An idler can solve the design problems<br />

above. Since an idler always imposes additional<br />

bending stresses on the belt, it usually is best to<br />

design the drive without idlers if possible. Also,<br />

from an economic standpoint, it is generally more<br />

cost effective to provide takeup by movement of<br />

either the driveR or driveN shaft rather than by<br />

inserting an idler.<br />

When using idlers, certain principles should be<br />

followed to obtain the best possible drive and to<br />

minimize common idler problems. The important<br />

design considerations are:<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Placement in the drive (inside vs. outside).<br />

Placement on tight or slack sides.<br />

Idler location in span.<br />

Diameter.<br />

Grooved or flat.<br />

Center distance, belt length, installation and<br />

takeup.<br />

Inside or Outside:<br />

Idlers may be placed either inside or outside the<br />

drive, as shown in Fig. 26 and Fig. 27.<br />

An inside idler decreases the arc of contact on the<br />

adjacent sheaves; whereas, a backside idler<br />

increases the arc of contact on the adjacent sheaves.<br />

Either may be used, but a backside idler must be<br />

larger (See Idler Diameters on Page 81). If a<br />

backside idler is used for belt takeup, the idler<br />

penetration (amount of takeup) is limited by the belt<br />

span on the opposite side of the drive.<br />

Figure 26 – Inside Idler<br />

Figure 27 – Outside or Backside Idler<br />

Backside idlers are always flat pulleys, since they<br />

contact the top of the Polyflex JB or Micro-V <strong>Belt</strong>.<br />

Inside idlers can be either flat or grooved. If they are<br />

grooved, the idler sheave must be machined<br />

correctly for the specific belt cross section. (See<br />

Sections VIII. Polyflex JB Sheave Groove<br />

Specifications and IX., Micro-V Pulley Groove<br />

Specifications on pages 83 and 84.<br />

A. Idler Placement In the Span<br />

Idler position in the span with respect to<br />

other sheaves.<br />

A grooved inside idler may be located at any point<br />

in the span, but preferably so that it results in nearly<br />

equal arcs of contact on the two adjacent sheaves.<br />

See Fig. 28 on Page 81.<br />

80 The World’s Most Trusted Name in <strong>Belt</strong>s, Hose & Hydraulics.