PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Polyflex ® JB ® <strong>Belt</strong> <strong>Drives</strong><br />

For information on additional Polyflex JB cross<br />

sections, see the Polyflex JB Drive Design Manual<br />

18595<br />

Developed and produced by Gates, Polyflex JB <strong>Belt</strong>s<br />

provide more load-carrying capacity at higher<br />

speeds on precision applications. “High power<br />

density” puts more power in small spaces. Polyflex<br />

JB <strong>Belt</strong>s Features and Benefits:<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

High modulus polyurethane compound resists<br />

fatigue, wear, ozone and most environmental<br />

conditions; and provides a high coefficient of<br />

friction<br />

Superior adhesion of tensile cords and specially<br />

compounded polyurethane for high fatigue<br />

resistance and long belt life<br />

Precision cast for dimensional accuracy and<br />

smooth operation<br />

60° angle to provide greater undercord support to<br />

the tensile cord and distribute the load more<br />

evenly<br />

Individual belts are joined for greater stability<br />

Ribbed construction to relieve bending stress on<br />

small sheaves and provide lateral rigidity<br />

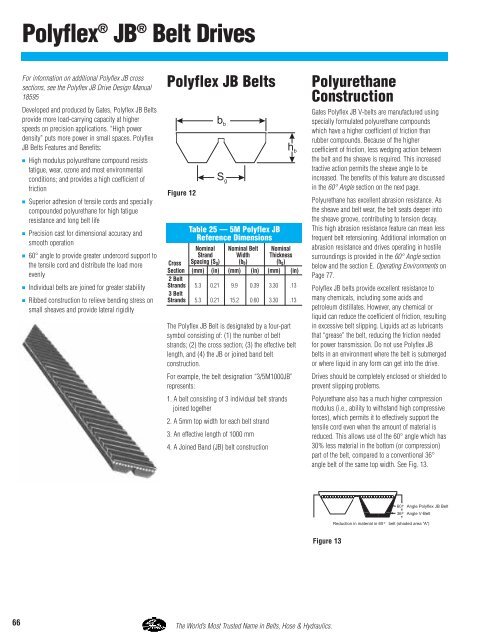

Polyflex JB <strong>Belt</strong>s<br />

Figure 12<br />

b b<br />

S g<br />

Standard Table <strong>Belt</strong> 25 Nomenclature — 5M Polyflex JB<br />

Reference Dimensions<br />

h b<br />

Nominal Nominal <strong>Belt</strong> Nominal<br />

Strand Width Thickness<br />

Cross Spacing (S g) (b b) (h g)<br />

Section (mm) (in) (mm) (in) (mm) (in)<br />

2 <strong>Belt</strong><br />

Strands 5.3 0.21 9.9 0.39 3.30 .13<br />

3 <strong>Belt</strong><br />

Strands 5.3 0.21 15.2 0.60 3.30 .13<br />

The Polyflex JB <strong>Belt</strong> is designated by a four-part<br />

symbol consisting of: (1) the number of belt<br />

strands; (2) the cross section; (3) the effective belt<br />

length, and (4) the JB or joined band belt<br />

construction.<br />

For example, the belt designation “3/5M1000JB”<br />

represents:<br />

1. A belt consisting of 3 individual belt strands<br />

joined together<br />

2. A 5mm top width for each belt strand<br />

3. An effective length of 1000 mm<br />

4. A Joined Band (JB) belt construction<br />

Polyurethane<br />

Construction<br />

Gates Polyflex JB V-belts are manufactured using<br />

specially formulated polyurethane compounds<br />

which have a higher coefficient of friction than<br />

rubber compounds. Because of the higher<br />

coefficient of friction, less wedging action between<br />

the belt and the sheave is required. This increased<br />

tractive action permits the sheave angle to be<br />

increased. The benefits of this feature are discussed<br />

in the 60° Angle section on the next page.<br />

Polyurethane has excellent abrasion resistance. As<br />

the sheave and belt wear, the belt seats deeper into<br />

the sheave groove, contributing to tension decay.<br />

This high abrasion resistance feature can mean less<br />

frequent belt retensioning. Additional information on<br />

abrasion resistance and drives operating in hostile<br />

surroundings is provided in the 60° Angle section<br />

below and the section E. Operating Environments on<br />

Page 77.<br />

Polyflex JB belts provide excellent resistance to<br />

many chemicals, including some acids and<br />

petroleum distillates. However, any chemical or<br />

liquid can reduce the coefficient of friction, resulting<br />

in excessive belt slipping. Liquids act as lubricants<br />

that “grease” the belt, reducing the friction needed<br />

for power transmission. Do not use Polyflex JB<br />

belts in an environment where the belt is submerged<br />

or where liquid in any form can get into the drive.<br />

<strong>Drives</strong> should be completely enclosed or shielded to<br />

prevent slipping problems.<br />

Polyurethane also has a much higher compression<br />

modulus (i.e., ability to withstand high compressive<br />

forces), which permits it to effectively support the<br />

tensile cord even when the amount of material is<br />

reduced. This allows use of the 60° angle which has<br />

30% less material in the bottom (or compression)<br />

part of the belt, compared to a conventional 36°<br />

angle belt of the same top width. See Fig. 13.<br />

60°<br />

Angle Polyflex JB <strong>Belt</strong><br />

36°<br />

Angle V-<strong>Belt</strong><br />

Reduction in material in 60°<br />

belt (shaded area “A”)<br />

Figure 13<br />

66 The World’s Most Trusted Name in <strong>Belt</strong>s, Hose & Hydraulics.