PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

PowerGrip® GT® Belt Drives

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Polyflex ® JB ® and Micro-V ® <strong>Belt</strong> Drive Selection Procedures<br />

How to Design Polyflex JB and Micro-V <strong>Belt</strong> <strong>Drives</strong>–continued<br />

Step 6 Determine the Minimum Installation<br />

and Takeup Allowances<br />

A. Find the recommended installation and takeup<br />

allowance in Engineering, Section V. Installation<br />

and Takeup Table 40 or Table 41 on Page 80.<br />

B. For optimum belt performance, the drive must<br />

have sufficient belt installation and takeup<br />

allowance. Tables 40 and 41 on Page 80 show<br />

DriveN Machine<br />

The machines listed below are representative<br />

samples only. Select the group listed below<br />

whose load characteristics most closely<br />

approximate those of the machine being considered.<br />

Agitators for Liquids<br />

Blowers and Exhausters<br />

Centrifugal Pumps & Compressors Display Equipment<br />

Dispensing Equipment<br />

Fans up to 10 Horsepower Instrumentation<br />

Light Duty conveyors<br />

Office Equipment<br />

<strong>Belt</strong> conveyors for Sand, Grain, Etc.<br />

Dough Mixers<br />

Fans - Over 10 Horsepower Generators<br />

Line Shafts<br />

Laundry Machinery<br />

Machine Tools<br />

Punches - Presses - Shears<br />

Printing Machinery<br />

Positive Displacement Rotary Pumps<br />

Brick Machinery<br />

Bucket Elevators<br />

Exciters<br />

Piston Compressors<br />

Conveyors (Drag-Pan-Screw)<br />

Piston Pumps<br />

Positive Displacement Blowers Textile Machinery<br />

Hoists<br />

Rubber Calendars - Extruders – Mills<br />

the required center distance movement to<br />

provide proper installation and takeup. However,<br />

if you have a fixed center drive, it also must<br />

have provisions for belt length adjustment. Use<br />

of idlers is the most common method to provide<br />

belt length adjustment with fixed center drives.<br />

See Engineering Section VI: Idler Usage on<br />

Page 80 and Section VII. Design of <strong>Drives</strong> With<br />

Idlers on Page 82.<br />

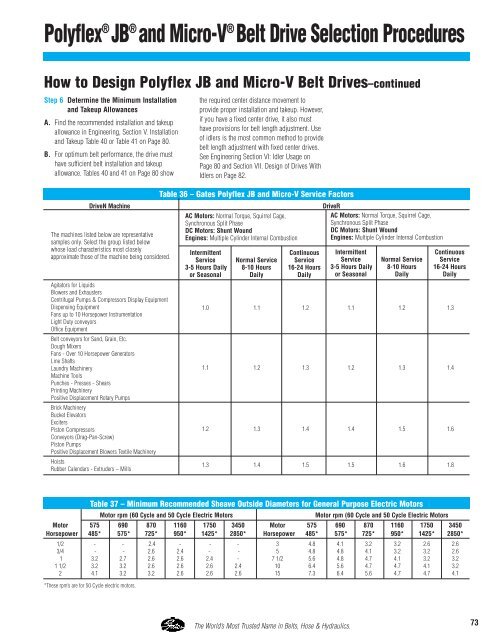

Table 36 – Gates Polyflex JB and Micro-V Service Factors<br />

DriveR<br />

AC Motors: Normal Torque, Squirrel Cage,<br />

Synchronous Split Phase<br />

DC Motors: Shunt Wound<br />

Engines: Multiple Cylinder Internal Combustion<br />

Intermittent<br />

Continuous<br />

Service Normal Service Service<br />

3-5 Hours Daily 8-10 Hours 16-24 Hours<br />

or Seasonal Daily Daily<br />

AC Motors: Normal Torque, Squirrel Cage,<br />

Synchronous Split Phase<br />

DC Motors: Shunt Wound<br />

Engines: Multiple Cylinder Internal Combustion<br />

Intermittent<br />

Continuous<br />

Service Normal Service Service<br />

3-5 Hours Daily 8-10 Hours 16-24 Hours<br />

or Seasonal Daily Daily<br />

1.0 1.1 1.2 1.1 1.2 1.3<br />

1.1 1.2 1.3 1.2 1.3 1.4<br />

1.2 1.3 1.4 1.4 1.5 1.6<br />

1.3 1.4 1.5 1.5 1.6 1.8<br />

Table 37 – Minimum Recommended Sheave Outside Diameters for General Purpose Electric Motors<br />

Motor rpm (60 Cycle and 50 Cycle Electric Motors<br />

Motor rpm (60 Cycle and 50 Cycle Electric Motors<br />

Motor 575 690 870 1160 1750 3450 Motor 575 690 870 1160 1750 3450<br />

Horsepower 485* 575* 725* 950* 1425* 2850* Horsepower 485* 575* 725* 950* 1425* 2850*<br />

1/2 - - 2.4 - - -<br />

3 4.8 4.1 3.2 3.2 2.6 2.6<br />

3/4 - - 2.6 2.4 - -<br />

5 4.8 4.8 4.1 3.2 3.2 2.6<br />

1 3.2 2.7 2.6 2.6 2.4 -<br />

7 1/2 5.6 4.8 4.7 4.1 3.2 3.2<br />

1 1/2 3.2 3.2 2.6 2.6 2.6 2.4<br />

10 6.4 5.6 4.7 4.7 4.1 3.2<br />

2 4.1 3.2 3.2 2.6 2.6 2.6<br />

15 7.3 6.4 5.6 4.7 4.7 4.1<br />

*These rpm’s are for 50 Cycle electric motors.<br />

The World’s Most Trusted Name in <strong>Belt</strong>s, Hose & Hydraulics.<br />

73