for the proposed 800 MW Combined Cycle Power Plant ...

for the proposed 800 MW Combined Cycle Power Plant ...

for the proposed 800 MW Combined Cycle Power Plant ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CO 2 Capture Study<br />

For <strong>800</strong> <strong>MW</strong> <strong>Power</strong> <strong>Plant</strong> – Tjeldbergodden<br />

1. The alternative of using an auxiliary boiler to provide <strong>the</strong> steam <strong>for</strong> <strong>the</strong><br />

CO2 capture plant has been demonstrated to be of lesser <strong>the</strong>rmal<br />

efficiency<br />

If <strong>the</strong> rules of integration are to be followed <strong>the</strong>n <strong>the</strong> alternatives are:<br />

2. Install <strong>the</strong> optimum steam turbine <strong>for</strong> <strong>the</strong> capture case and accept <strong>the</strong><br />

inefficiency resulting while <strong>the</strong> capture plant is not present.<br />

3. Install <strong>the</strong> optimum steam turbine <strong>for</strong> <strong>the</strong> capture case and add a small<br />

steam turbine to accept <strong>the</strong> steam which will be used by <strong>the</strong> capture plant<br />

when it is eventually commissioned<br />

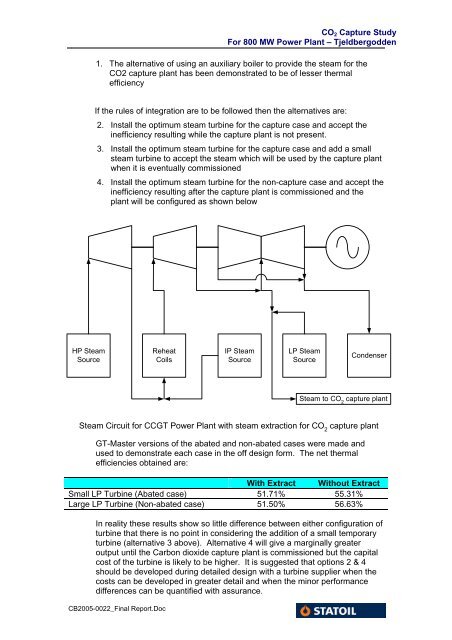

4. Install <strong>the</strong> optimum steam turbine <strong>for</strong> <strong>the</strong> non-capture case and accept <strong>the</strong><br />

inefficiency resulting after <strong>the</strong> capture plant is commissioned and <strong>the</strong><br />

plant will be configured as shown below<br />

HP Steam<br />

Source<br />

Reheat<br />

Coils<br />

IP Steam<br />

Source<br />

LP Steam<br />

Source<br />

Condenser<br />

Steam to CO 2<br />

capture plant<br />

Steam Circuit <strong>for</strong> CCGT <strong>Power</strong> <strong>Plant</strong> with steam extraction <strong>for</strong> CO 2<br />

capture plant<br />

GT-Master versions of <strong>the</strong> abated and non-abated cases were made and<br />

used to demonstrate each case in <strong>the</strong> off design <strong>for</strong>m. The net <strong>the</strong>rmal<br />

efficiencies obtained are:<br />

With Extract Without Extract<br />

Small LP Turbine (Abated case) 51.71% 55.31%<br />

Large LP Turbine (Non-abated case) 51.50% 56.63%<br />

In reality <strong>the</strong>se results show so little difference between ei<strong>the</strong>r configuration of<br />

turbine that <strong>the</strong>re is no point in considering <strong>the</strong> addition of a small temporary<br />

turbine (alternative 3 above). Alternative 4 will give a marginally greater<br />

output until <strong>the</strong> Carbon dioxide capture plant is commissioned but <strong>the</strong> capital<br />

cost of <strong>the</strong> turbine is likely to be higher. It is suggested that options 2 & 4<br />

should be developed during detailed design with a turbine supplier when <strong>the</strong><br />

costs can be developed in greater detail and when <strong>the</strong> minor per<strong>for</strong>mance<br />

differences can be quantified with assurance.<br />

CB2005-0022_Final Report.Doc