for the proposed 800 MW Combined Cycle Power Plant ...

for the proposed 800 MW Combined Cycle Power Plant ...

for the proposed 800 MW Combined Cycle Power Plant ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CO 2 Capture Study<br />

For <strong>800</strong> <strong>MW</strong> <strong>Power</strong> <strong>Plant</strong> – Tjeldbergodden<br />

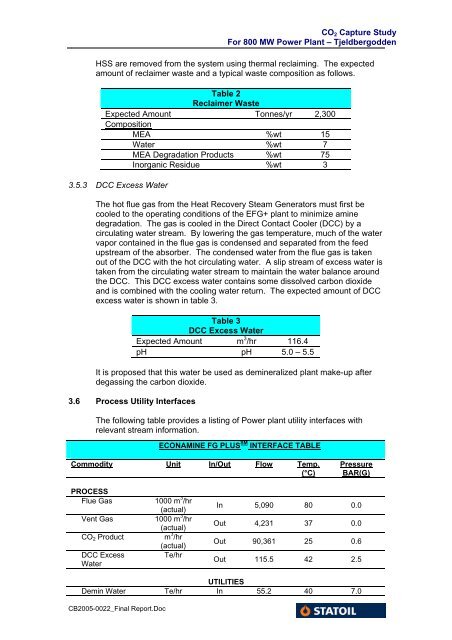

HSS are removed from <strong>the</strong> system using <strong>the</strong>rmal reclaiming. The expected<br />

amount of reclaimer waste and a typical waste composition as follows.<br />

Table 2<br />

Reclaimer Waste<br />

Expected Amount Tonnes/yr 2,300<br />

Composition<br />

MEA %wt 15<br />

Water %wt 7<br />

MEA Degradation Products %wt 75<br />

Inorganic Residue %wt 3<br />

3.5.3 DCC Excess Water<br />

The hot flue gas from <strong>the</strong> Heat Recovery Steam Generators must first be<br />

cooled to <strong>the</strong> operating conditions of <strong>the</strong> EFG+ plant to minimize amine<br />

degradation. The gas is cooled in <strong>the</strong> Direct Contact Cooler (DCC) by a<br />

circulating water stream. By lowering <strong>the</strong> gas temperature, much of <strong>the</strong> water<br />

vapor contained in <strong>the</strong> flue gas is condensed and separated from <strong>the</strong> feed<br />

upstream of <strong>the</strong> absorber. The condensed water from <strong>the</strong> flue gas is taken<br />

out of <strong>the</strong> DCC with <strong>the</strong> hot circulating water. A slip stream of excess water is<br />

taken from <strong>the</strong> circulating water stream to maintain <strong>the</strong> water balance around<br />

<strong>the</strong> DCC. This DCC excess water contains some dissolved carbon dioxide<br />

and is combined with <strong>the</strong> cooling water return. The expected amount of DCC<br />

excess water is shown in table 3.<br />

Table 3<br />

DCC Excess Water<br />

Expected Amount m 3 /hr 116.4<br />

pH pH 5.0 – 5.5<br />

It is <strong>proposed</strong> that this water be used as demineralized plant make-up after<br />

degassing <strong>the</strong> carbon dioxide.<br />

3.6 Process Utility Interfaces<br />

The following table provides a listing of <strong>Power</strong> plant utility interfaces with<br />

relevant stream in<strong>for</strong>mation.<br />

ECONAMINE FG PLUS SM INTERFACE TABLE<br />

Commodity Unit In/Out Flow Temp.<br />

(°C)<br />

Pressure<br />

BAR(G)<br />

PROCESS<br />

Flue Gas<br />

Vent Gas<br />

CO 2 Product<br />

DCC Excess<br />

Water<br />

1000 m 3 /hr<br />

(actual)<br />

1000 m 3 /hr<br />

(actual)<br />

m 3 /hr<br />

(actual)<br />

Te/hr<br />

In 5,090 80 0.0<br />

Out 4,231 37 0.0<br />

Out 90,361 25 0.6<br />

Out 115.5 42 2.5<br />

UTILITIES<br />

Demin Water Te/hr In 55.2 40 7.0<br />

CB2005-0022_Final Report.Doc