for the proposed 800 MW Combined Cycle Power Plant ...

for the proposed 800 MW Combined Cycle Power Plant ...

for the proposed 800 MW Combined Cycle Power Plant ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CO 2 Capture Study<br />

For <strong>800</strong> <strong>MW</strong> <strong>Power</strong> <strong>Plant</strong> – Tjeldbergodden<br />

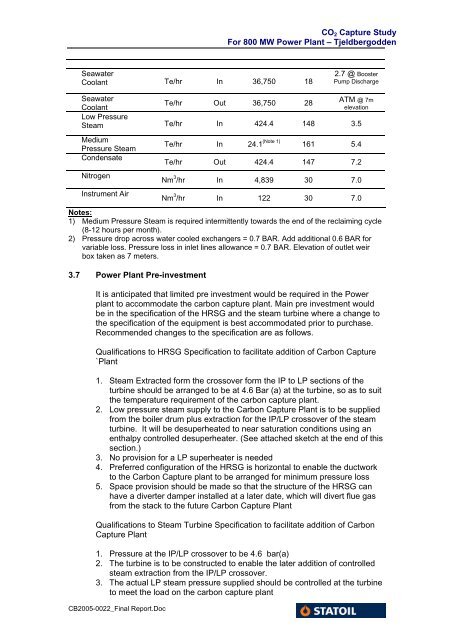

Seawater<br />

Coolant Te/hr In 36,750 18<br />

2.7 @ Booster<br />

Pump Discharge<br />

Seawater<br />

Coolant<br />

Te/hr Out 36,750 28<br />

Low Pressure<br />

Steam Te/hr In 424.4 148 3.5<br />

Medium<br />

Pressure Steam<br />

Condensate<br />

Nitrogen<br />

Instrument Air<br />

CB2005-0022_Final Report.Doc<br />

ATM @ 7m<br />

elevation<br />

Te/hr In 24.1 (Note 1) 161 5.4<br />

Te/hr Out 424.4 147 7.2<br />

Nm 3 /hr In 4,839 30 7.0<br />

Nm 3 /hr In 122 30 7.0<br />

Notes:<br />

1) Medium Pressure Steam is required intermittently towards <strong>the</strong> end of <strong>the</strong> reclaiming cycle<br />

(8-12 hours per month).<br />

2) Pressure drop across water cooled exchangers = 0.7 BAR. Add additional 0.6 BAR <strong>for</strong><br />

variable loss. Pressure loss in inlet lines allowance = 0.7 BAR. Elevation of outlet weir<br />

box taken as 7 meters.<br />

3.7 <strong>Power</strong> <strong>Plant</strong> Pre-investment<br />

It is anticipated that limited pre investment would be required in <strong>the</strong> <strong>Power</strong><br />

plant to accommodate <strong>the</strong> carbon capture plant. Main pre investment would<br />

be in <strong>the</strong> specification of <strong>the</strong> HRSG and <strong>the</strong> steam turbine where a change to<br />

<strong>the</strong> specification of <strong>the</strong> equipment is best accommodated prior to purchase.<br />

Recommended changes to <strong>the</strong> specification are as follows.<br />

Qualifications to HRSG Specification to facilitate addition of Carbon Capture<br />

`<strong>Plant</strong><br />

1. Steam Extracted <strong>for</strong>m <strong>the</strong> crossover <strong>for</strong>m <strong>the</strong> IP to LP sections of <strong>the</strong><br />

turbine should be arranged to be at 4.6 Bar (a) at <strong>the</strong> turbine, so as to suit<br />

<strong>the</strong> temperature requirement of <strong>the</strong> carbon capture plant.<br />

2. Low pressure steam supply to <strong>the</strong> Carbon Capture <strong>Plant</strong> is to be supplied<br />

from <strong>the</strong> boiler drum plus extraction <strong>for</strong> <strong>the</strong> IP/LP crossover of <strong>the</strong> steam<br />

turbine. It will be desuperheated to near saturation conditions using an<br />

enthalpy controlled desuperheater. (See attached sketch at <strong>the</strong> end of this<br />

section.)<br />

3. No provision <strong>for</strong> a LP superheater is needed<br />

4. Preferred configuration of <strong>the</strong> HRSG is horizontal to enable <strong>the</strong> ductwork<br />

to <strong>the</strong> Carbon Capture plant to be arranged <strong>for</strong> minimum pressure loss<br />

5. Space provision should be made so that <strong>the</strong> structure of <strong>the</strong> HRSG can<br />

have a diverter damper installed at a later date, which will divert flue gas<br />

from <strong>the</strong> stack to <strong>the</strong> future Carbon Capture <strong>Plant</strong><br />

Qualifications to Steam Turbine Specification to facilitate addition of Carbon<br />

Capture <strong>Plant</strong><br />

1. Pressure at <strong>the</strong> IP/LP crossover to be 4.6 bar(a)<br />

2. The turbine is to be constructed to enable <strong>the</strong> later addition of controlled<br />

steam extraction from <strong>the</strong> IP/LP crossover.<br />

3. The actual LP steam pressure supplied should be controlled at <strong>the</strong> turbine<br />

to meet <strong>the</strong> load on <strong>the</strong> carbon capture plant