Application Note AN-1035 - International Rectifier

Application Note AN-1035 - International Rectifier

Application Note AN-1035 - International Rectifier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Compression tests<br />

Method<br />

• Tests were carried out at ambient room<br />

temperature (22 o C).<br />

• Test speed was:<br />

0.5mmmin -1 for the MQ- and MT-outlines<br />

1.2mmmin -1 for the L8-outline<br />

(return speed of 20mmmin -1 where applicable).<br />

• Test duration was measured from the point at<br />

which the tester registered a force of:<br />

0.05N for the MQ- and MT-outlines<br />

1.00N for the L8-outline.<br />

• The test was terminated if the force reached:<br />

1750N for the MQ- and MT-outlines<br />

2000N for the L8-outline.<br />

Continuous pressure:<br />

Force was applied to the top of the device until the<br />

gate threshold voltage (V g-th ) shifted by ±20% (or until<br />

the maximum force for the outline was reached).<br />

Stepped pressure:<br />

MQ-outline: Force was raised to 400N, relieved and<br />

the device allowed to return to neutral. The force was<br />

then raised to 700N and relieved; this process was<br />

repeated in steps of 50N until the device failed. The<br />

gate threshold was monitored throughout.<br />

MT-outline: The MQ-outline test was replicated but<br />

with an initial force of 600N and increments of 100N.<br />

L8-outline: The MT-outline test was replicated but with<br />

an initial force of 1200N and termination force of<br />

2000N (the maximum available on the equipment).<br />

<strong>Note</strong>: Initial pressures were set close to the expected failure<br />

point to minimize the number of cycles and, therefore, the<br />

fatigue induced by them.<br />

Results<br />

The table below shows the average compression<br />

required to cause failure in DirectFET devices.<br />

MQ-outline MT-outline L8-outline<br />

Continuous 1204N 1407N no failures<br />

Stepped 663N 1106N no failures<br />

<strong>Note</strong>: Gravity (1g) was assumed to be 9.81ms -2 .<br />

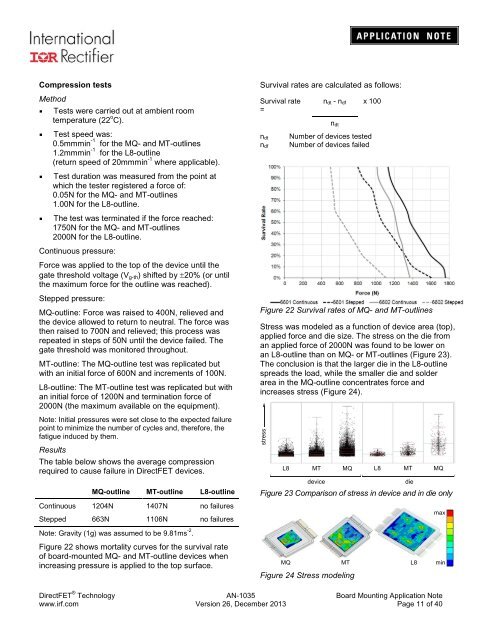

Figure 22 shows mortality curves for the survival rate<br />

of board-mounted MQ- and MT-outline devices when<br />

increasing pressure is applied to the top surface.<br />

Survival rates are calculated as follows:<br />

Survival rate<br />

=<br />

n dt<br />

n df<br />

n dt - n df x 100<br />

n dt<br />

Number of devices tested<br />

Number of devices failed<br />

Figure 22 Survival rates of MQ- and MT-outlines<br />

Stress was modeled as a function of device area (top),<br />

applied force and die size. The stress on the die from<br />

an applied force of 2000N was found to be lower on<br />

an L8-outline than on MQ- or MT-outlines (Figure 23).<br />

The conclusion is that the larger die in the L8-outline<br />

spreads the load, while the smaller die and solder<br />

area in the MQ-outline concentrates force and<br />

increases stress (Figure 24).<br />

stress<br />

L8 MT MQ L8 MT MQ<br />

device die<br />

Figure 23 Comparison of stress in device and in die only<br />

MQ MT L8<br />

Figure 24 Stress modeling<br />

max<br />

min<br />

DirectFET ® Technology <strong>AN</strong>-<strong>1035</strong> Board Mounting <strong>Application</strong> <strong>Note</strong><br />

www.irf.com Version 26, December 2013 Page 11 of 40