GRAIN DRYER & PARTS BOOK - Opico

GRAIN DRYER & PARTS BOOK - Opico

GRAIN DRYER & PARTS BOOK - Opico

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2. PLENUM HIGH LIMIT CONTROL<br />

The high limit control safeguards against excessive plenum temperatures. The maximum temperature is<br />

factory set and microprocessor controlled. An additional high limit thermostat is placed in the plenum and acts in<br />

conjunction with the microprocessor. During the initial start-up of the dryer the microprocessor checks the high<br />

limit thermostat to make certain the plenum temperature falls within the operating range. If so, operation continues<br />

and the dryer begins the cycle. Should the thermostat open at any time during operation, power to the controller<br />

will be interrupted, halting operation of the entire unit.<br />

3. LOADING THE BIN<br />

DANGER<br />

The loading auger operates automatically and may start without notice. Make certain that the auger is<br />

free of debris and that everyone stays clear of the intake. Failure to do so may result in serious injury<br />

or death.<br />

The standard loading hopper may be used in conjunction with bin unloading equipment or it may be<br />

extended to reach under a hopper bottom bin. An auxiliary outlet is also provided which becomes energized as<br />

the dryer begins to load. This outlet can be used to operate an auxiliary electric auger, such as a bin unloader or<br />

transport auger, to fill the dryer. The grain can also be loaded directly into the top of the dryer.<br />

When the loading hopper attachment is used for filling the dryer, follow these steps to prevent the grain<br />

from being fed into the dryer faster than the vertical auger can recirculate it. When this happens the grai.n can<br />

build up in the bottom of the dryer until it gets into the agitator assembly and causes damage to the agitator.<br />

A. Make sure that the vertical auger drive belt is kept tight and is not slipping.<br />

B. Make sure the discharge holes at the top of the vertical auger housing are completely open with<br />

the swivel head in the recirculation position.<br />

C. Make sure that the bottom auger well is kept clean of trash or fine material build up which restricts<br />

the flow of grain into the intake of the vertical auger.<br />

D. The vertical auger flighting cannot be worn down at the intake end.<br />

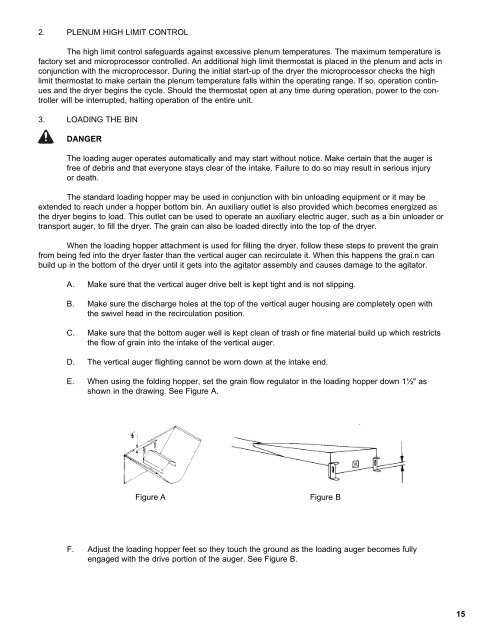

E. When using the folding hopper, set the grain flow regulator in the loading hopper down 1½" as<br />

shown in the drawing. See Figure A.<br />

Figure A<br />

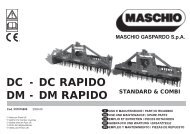

Figure B<br />

F. Adjust the loading hopper feet so they touch the ground as the loading auger becomes fully<br />

engaged with the drive portion of the auger. See Figure B.<br />

15