United Nations Environment Programme - Stockholm Convention on ...

United Nations Environment Programme - Stockholm Convention on ...

United Nations Environment Programme - Stockholm Convention on ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5 CASE STUDIES<br />

5.1 FORMATION AND RELEASE OF POPS IN THE CEMENT INDUSTRY AND THE<br />

USE OF ALTERNATIVE FUELS,<br />

BY WILLEM VAN LOO (VIENNA CONSULTATION)<br />

Slide 1<br />

<str<strong>on</strong>g>Stockholm</str<strong>on</strong>g> <str<strong>on</strong>g>C<strong>on</strong>venti<strong>on</strong></str<strong>on</strong>g>: Regi<strong>on</strong>al C<strong>on</strong>sultati<strong>on</strong> for<br />

Central and Eastern European countries <strong>on</strong> the POP’s<br />

BAT and BEP Guidelines<br />

Slide 4<br />

The rawmaterials are burnt at 1450° C to form<br />

clinker<br />

Formati<strong>on</strong> and Release of POP’s in<br />

the Cement Industry and the Use of<br />

Alternative Fuels<br />

Vienna, 9-11 February 2005<br />

By Willem van Loo – CEMBUREAU/CSI<br />

Slide 2<br />

Slide 5<br />

Producti<strong>on</strong> of cement<br />

Raw material<br />

Raw meal<br />

ESP<br />

SUBSTITUTION OF FOSSIL FUELS IN<br />

CLINKER MANUFACTURING<br />

quarry<br />

blending basin<br />

kiln<br />

Rohmü hle<br />

Clinker<br />

storage bin<br />

Cement mill<br />

Cement<br />

storage bin<br />

dispatch<br />

gas<br />

solid<br />

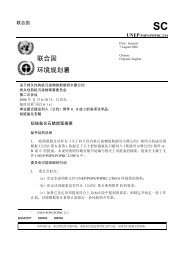

Slide 3<br />

Rotary kiln with suspensi<strong>on</strong> preheater and calciner<br />

suspensi<strong>on</strong><br />

preheater<br />

850 °C<br />

to raw mill and ESP<br />

300 - 350 °C<br />

raw meal<br />

calciner<br />

1100 °C<br />

fuel<br />

tertiary air c<strong>on</strong>duct<br />

700 - 1000 °C<br />

fuel<br />

700 - 1000 °C<br />

clinker cooler<br />

exhaust air 200 °C - 350 °C<br />

rotary kiln 2000 °C<br />

cooler vent air<br />

clinker<br />

clinker cooler<br />

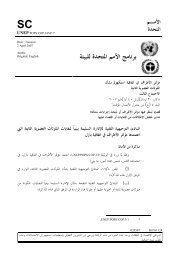

Slide 6<br />

FUEL SUBSTITUTION IN<br />

THE KILN FIRING PROCESS<br />

Types of alternative<br />

fuels<br />

• animal meal<br />

• rubber tyres<br />

• waste oil<br />

• impregnated saw dust<br />

• solvents<br />

• sewage sludge<br />

• paper sludge<br />

• ………..<br />

Substituti<strong>on</strong> Rate in<br />

Europe<br />

12% or 4.4 Mt<strong>on</strong>nes<br />

71