Energy technology: a new business area - Scherdel GmbH

Energy technology: a new business area - Scherdel GmbH

Energy technology: a new business area - Scherdel GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RESEARCH & DEVELOPMENT<br />

Industrial waste heat,<br />

a valuable ‘resource’<br />

Absorption chiller from Econ Energietechnik<br />

<strong>GmbH</strong> cools server centre in Dessau<br />

MECHANICAL ENGINEERING – LOCATIONS – TECHNOLOGY & PRODUCT DEVELOPMENT – NEWS AND INFORMATION<br />

Contact data<br />

Econ<br />

Energietechnik <strong>GmbH</strong><br />

Marco Bauer<br />

<strong>Scherdel</strong>straße 2<br />

D-95643 Marktredwitz<br />

Tel.: +49 (0) 9231 603-556<br />

Fax: +49 (0) 9231 603-621<br />

Email:<br />

marco.bauer@econ-web.de<br />

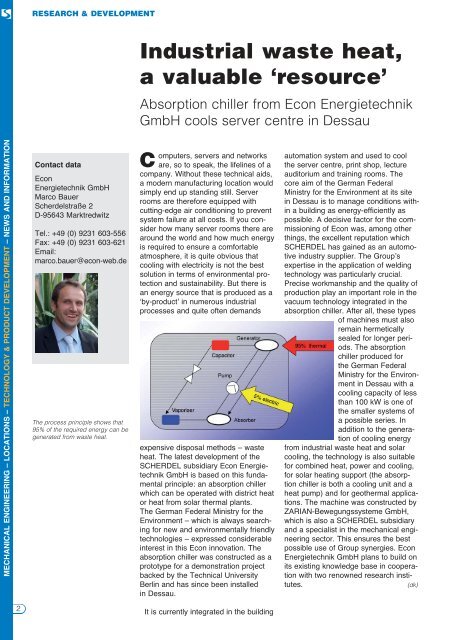

The process principle shows that<br />

95% of the required energy can be<br />

generated from waste heat.<br />

C<br />

omputers, servers and networks<br />

are, so to speak, the lifelines of a<br />

company. Without these technical aids,<br />

a modern manufacturing location would<br />

simply end up standing still. Server<br />

rooms are therefore equipped with<br />

cutting-edge air conditioning to prevent<br />

system failure at all costs. If you consider<br />

how many server rooms there are<br />

around the world and how much energy<br />

is required to ensure a comfortable<br />

atmosphere, it is quite obvious that<br />

cooling with electricity is not the best<br />

solution in terms of environmental protection<br />

and sustainability. But there is<br />

an energy source that is produced as a<br />

ʻby-productʼ in numerous industrial<br />

processes and quite often demands<br />

expensive disposal methods – waste<br />

heat. The latest development of the<br />

SCHERDEL subsidiary Econ Energietechnik<br />

<strong>GmbH</strong> is based on this fundamental<br />

principle: an absorption chiller<br />

which can be operated with district heat<br />

or heat from solar thermal plants.<br />

The German Federal Ministry for the<br />

Environment – which is always searching<br />

for <strong>new</strong> and environmentally friendly<br />

technologies – expressed considerable<br />

interest in this Econ innovation. The<br />

absorption chiller was constructed as a<br />

prototype for a demonstration project<br />

backed by the Technical University<br />

Berlin and has since been installed<br />

in Dessau.<br />

automation system and used to cool<br />

the server centre, print shop, lecture<br />

auditorium and training rooms. The<br />

core aim of the German Federal<br />

Ministry for the Environment at its site<br />

in Dessau is to manage conditions within<br />

a building as energy-efficiently as<br />

possible. A decisive factor for the commissioning<br />

of Econ was, among other<br />

things, the excellent reputation which<br />

SCHERDEL has gained as an automotive<br />

industry supplier. The Groupʼs<br />

expertise in the application of welding<br />

<strong>technology</strong> was particularly crucial.<br />

Precise workmanship and the quality of<br />

production play an important role in the<br />

vacuum <strong>technology</strong> integrated in the<br />

absorption chiller. After all, these types<br />

of machines must also<br />

remain hermetically<br />

sealed for longer periods.<br />

The absorption<br />

chiller produced for<br />

the German Federal<br />

Ministry for the Environment<br />

in Dessau with a<br />

cooling capacity of less<br />

than 100 kW is one of<br />

the smaller systems of<br />

a possible series. In<br />

addition to the generation<br />

of cooling energy<br />

from industrial waste heat and solar<br />

cooling, the <strong>technology</strong> is also suitable<br />

for combined heat, power and cooling,<br />

for solar heating support (the absorption<br />

chiller is both a cooling unit and a<br />

heat pump) and for geothermal applications.<br />

The machine was constructed by<br />

ZARIAN-Bewegungssysteme <strong>GmbH</strong>,<br />

which is also a SCHERDEL subsidiary<br />

and a specialist in the mechanical engineering<br />

sector. This ensures the best<br />

possible use of Group synergies. Econ<br />

Energietechnik <strong>GmbH</strong> plans to build on<br />

its existing knowledge base in cooperation<br />

with two renowned research institutes.<br />

(dk)<br />

2<br />

It is currently integrated in the building