4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

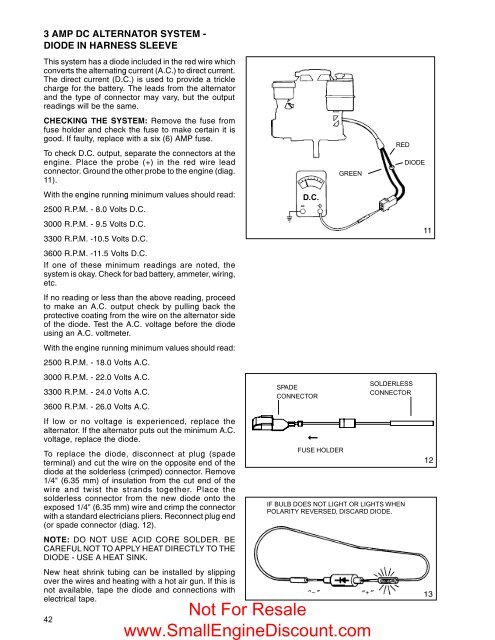

3 AMP DC ALTERNATOR SYSTEM -<br />

DIODE IN HARNESS SLEEVE<br />

This system has a diode included in the red wire which<br />

converts the alternating current (A.C.) to direct current.<br />

The direct current (D.C.) is used to provide a trickle<br />

charge for the battery. The leads from the alternator<br />

and the type of connector may vary, but the output<br />

readings will be the same.<br />

CHECKING THE SYSTEM: Remove the fuse from<br />

fuse holder and check the fuse to make certain it is<br />

good. If faulty, replace with a six (6) AMP fuse.<br />

To check D.C. output, separate the connectors at the<br />

engine. Place the probe (+) in the red wire lead<br />

connector. Ground the other probe to the engine (diag.<br />

11).<br />

With the engine running minimum values should read:<br />

2500 R.P.M. - 8.0 Volts D.C.<br />

3000 R.P.M. - 9.5 Volts D.C.<br />

3300 R.P.M. -10.5 Volts D.C.<br />

3600 R.P.M. -11.5 Volts D.C.<br />

If one of these minimum readings are noted, the<br />

system is okay. Check for bad battery, ammeter, wiring,<br />

etc.<br />

If no reading or less than the above reading, proceed<br />

to make an A.C. output check by pulling back the<br />

protective coating from the wire on the alternator side<br />

of the diode. Test the A.C. voltage before the diode<br />

using an A.C. voltmeter.<br />

With the engine running minimum values should read:<br />

2500 R.P.M. - 18.0 Volts A.C.<br />

3000 R.P.M. - 22.0 Volts A.C.<br />

3300 R.P.M. - 24.0 Volts A.C.<br />

3600 R.P.M. - 26.0 Volts A.C.<br />

If low or no voltage is experienced, replace the<br />

alternator. If the alternator puts out the minimum A.C.<br />

voltage, replace the diode.<br />

To replace the diode, disconnect at plug (spade<br />

terminal) and cut the wire on the opposite end of the<br />

diode at the solderless (crimped) connector. Remove<br />

1/4" (6.35 mm) of insulation from the cut end of the<br />

wire and twist the strands together. Place the<br />

solderless connector from the new diode onto the<br />

exposed 1/4" (6.35 mm) wire and crimp the connector<br />

with a standard electricians pliers. Reconnect plug end<br />

(or spade connector (diag. 12).<br />

NOTE: DO NOT USE ACID CORE SOLDER. BE<br />

CAREFUL NOT TO APPLY HEAT DIRECTLY TO THE<br />

DIODE - USE A HEAT SINK.<br />

New heat shrink tubing can be installed by slipping<br />

over the wires and heating with a hot air gun. If this is<br />

not available, tape the diode and connections with<br />

electrical tape.<br />

42<br />

D.C.<br />

SPADE<br />

CONNECTOR<br />

FUSE HOLDER<br />

GREEN<br />

RED<br />

IF BULB DOES NOT LIGHT OR LIGHTS WHEN<br />

POLARITY REVERSED, DISCARD DIODE.<br />

Not For Resale<br />

www.<strong>Small</strong><strong>Engine</strong><strong>Discount</strong>.com<br />

Þ<br />

SOLDERLESS<br />

CONNECTOR<br />

DIODE<br />

11<br />

12<br />

13