4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGINE VIBRATES EXCESSIVELY<br />

64<br />

1. Remove the spark plug wire. Check the engine crankshaft on the PTO end for bends using a straight<br />

edge, square or a dial indicator. Blades or adapters must be removed. Significant deflection will cause<br />

a vibration problem.<br />

2. Check the engine mounting bolts, make sure they are tight.<br />

3. Remove and check the attached equipment for an out of balance condition.<br />

4. If the engine is equipped with a counterbalance shaft, check the gear timing to determine if the<br />

counterbalance is out of time.<br />

BREATHER PASSING OIL<br />

1. Check the oil level, make sure the engine is<br />

not overfilled. Also verify that the viscosity<br />

rating on the container of the oil being used is<br />

to specification.<br />

2. Check the angle of operation. Avoid prolonged<br />

use at a severe angle.<br />

3. Check the engine R.P.M. setting for excessive<br />

R.P.M. using a vibratach or other tachometer<br />

and compare it to the R.P.M. settings found<br />

on microfiche card # 30 according to the<br />

engine model and specification number.<br />

Adjust the high and low R.P.M. as necessary.<br />

4. Check for leaking or damaged gaskets, seals,<br />

or "O"-rings. External leaks may not be<br />

evident; however, the leak may prevent the<br />

engine from achieving a partial crankcase<br />

vacuum.<br />

5. Check the breather for damage, dirty<br />

condition, or improper installation. The oil<br />

return hole(s) must face down.<br />

6. Check the engine compression using a<br />

compression tester. If the engine has weak<br />

compression, determine the cause of weak<br />

compression: worn rings, leaking head gasket,<br />

or leaking valves. Follow the compression<br />

tester's procedure.<br />

EXCESSIVE OIL CONSUMPTION<br />

1. Check the oil level, oil viscosity on the container of the oil being used, and oil condition. Replace and fill<br />

to the proper level.<br />

2. Check the angle of operation. Avoid prolonged use at a severe angle.<br />

3. Check for leaking or damaged gaskets, seals, or "O"-rings. External leaks may not be evident, however,<br />

the leak may prevent the engine from achieving a partial crankcase vacuum.<br />

4. Check the engine R.P.M. setting using a vibratach or other tachometer and compare it to the R.P.M.<br />

settings found on microfiche card # 30 according to the engine model and specification number. Adjust<br />

as necessary. The computer parts lookup systems also have RPM information listed in each individual<br />

engine parts list.<br />

5. Check the breather for damage, dirty condition, or improper installation. The oil return hole(s) must<br />

face down.<br />

6. Clean the cooling fins to prevent overheating.<br />

7. Check the carburetor setting causing a lean running condition, overheating the engine.<br />

8. Check the engine compression using a compression tester. If the engine has weak compression,<br />

determine the cause of weak compression: worn rings, leaking head gasket, or leaking valves. Follow<br />

the compression tester's procedure.<br />

9. Check the valve guide clearance for excessive wear.<br />

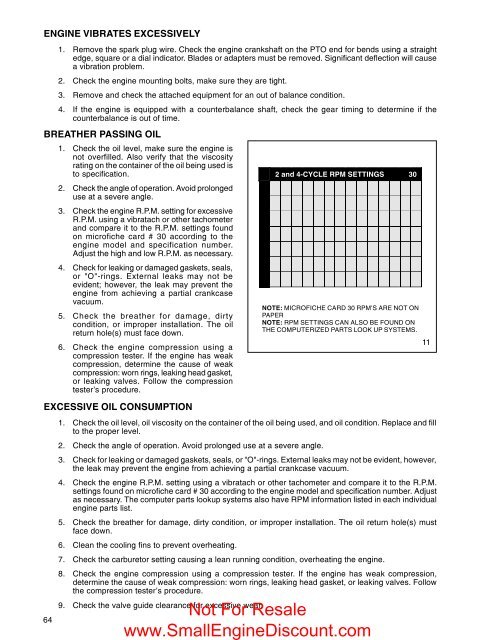

2 and 4-<strong>CYCLE</strong> RPM SETTINGS 30<br />

NOTE: MICROFICHE CARD 30 RPM'S ARE NOT ON<br />

PAPER<br />

NOTE: RPM SETTINGS CAN ALSO BE FOUND ON<br />

THE COMPUTERIZED PARTS LOOK UP SYSTEMS.<br />

11<br />

Not For Resale<br />

www.<strong>Small</strong><strong>Engine</strong><strong>Discount</strong>.com