4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

4-CYCLE OVERHEAD VALVE ENGINES - Small Engine Discount

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CYLINDERS<br />

Visually check the cylinder for broken or cracked fins<br />

or a scored cylinder bore. Check the main bearing for<br />

wear or scoring. If the main bearing is worn or scored<br />

it can be replaced on some models. See "Crankshaft<br />

Bearing Service" in this chapter.<br />

Use a dial bore gauge or transfer gauge with a<br />

micrometer to accurately measure the cylinder bore.<br />

Measure in the piston travel area approximately 1/2"<br />

to 3/4" (12.7-19.05 mm) from the top and the bottom<br />

. Measure at 90 degrees to the piston pin, 45 degrees<br />

to the piston pin, and even with the piston pin as the<br />

piston would appear when assembled. A rigid hone is<br />

recommended to "true" any cylinder irregularities. If<br />

the cylinder bore is worn more than .005" (.127 mm)<br />

oversize, out of round or scored, it should be replaced<br />

or re-sized to .010" or .020" (.254-.508 mm) oversize.<br />

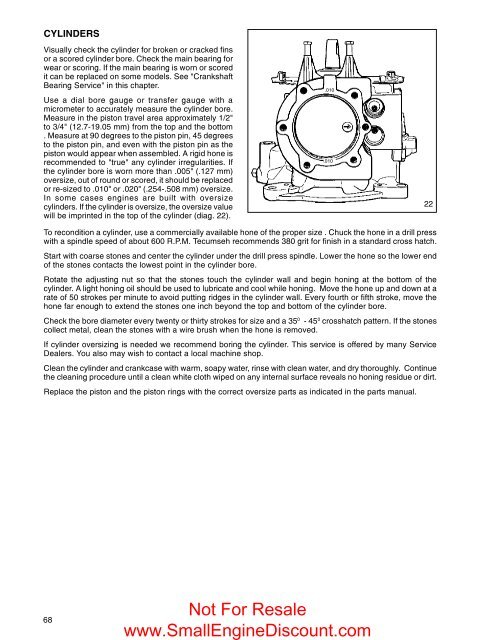

In some cases engines are built with oversize<br />

cylinders. If the cylinder is oversize, the oversize value<br />

will be imprinted in the top of the cylinder (diag. 22).<br />

.010<br />

.010<br />

22<br />

To recondition a cylinder, use a commercially available hone of the proper size . Chuck the hone in a drill press<br />

with a spindle speed of about 600 R.P.M. Tecumseh recommends 380 grit for finish in a standard cross hatch.<br />

Start with coarse stones and center the cylinder under the drill press spindle. Lower the hone so the lower end<br />

of the stones contacts the lowest point in the cylinder bore.<br />

Rotate the adjusting nut so that the stones touch the cylinder wall and begin honing at the bottom of the<br />

cylinder. A light honing oil should be used to lubricate and cool while honing. Move the hone up and down at a<br />

rate of 50 strokes per minute to avoid putting ridges in the cylinder wall. Every fourth or fifth stroke, move the<br />

hone far enough to extend the stones one inch beyond the top and bottom of the cylinder bore.<br />

Check the bore diameter every twenty or thirty strokes for size and a 35 0 - 45 0 crosshatch pattern. If the stones<br />

collect metal, clean the stones with a wire brush when the hone is removed.<br />

If cylinder oversizing is needed we recommend boring the cylinder. This service is offered by many Service<br />

Dealers. You also may wish to contact a local machine shop.<br />

Clean the cylinder and crankcase with warm, soapy water, rinse with clean water, and dry thoroughly. Continue<br />

the cleaning procedure until a clean white cloth wiped on any internal surface reveals no honing residue or dirt.<br />

Replace the piston and the piston rings with the correct oversize parts as indicated in the parts manual.<br />

68<br />

Not For Resale<br />

www.<strong>Small</strong><strong>Engine</strong><strong>Discount</strong>.com