Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

(+ flange) and the monopiles. The design temperature<br />

of the transition piece was -10°C (above<br />

LAT - Lowest Anticipated Tide) and 0° (below<br />

LAT) for the monopiles, whereas the lowest CVN<br />

test temperature was -50°C, valid for the thickest<br />

wall sections of the transition pieces. The<br />

construction was subject to GL Rules &<br />

Regulations IV Part 2: Regulations for the<br />

certification of Offshore Wind Energy Conversion<br />

Systems Edition 1999.<br />

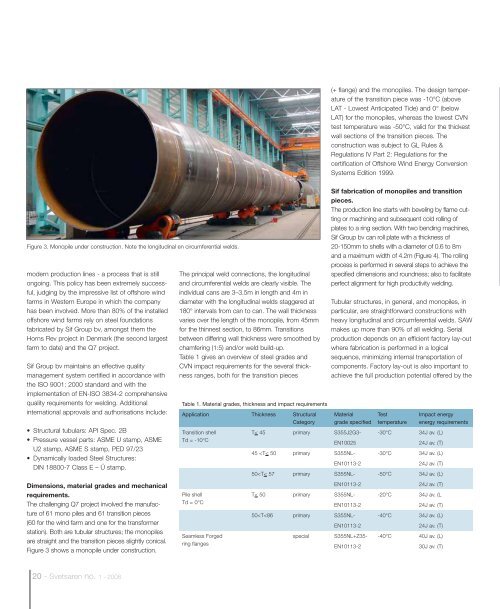

Figure 3. Monopile under construction. Note the longitudinal en circumferential welds.<br />

modern production lines - a process that is still<br />

ongoing. This policy has been extremely successful,<br />

judging by the impressive list of offshore wind<br />

farms in Western Europe in which the company<br />

has been involved. More than 80% of the installed<br />

offshore wind farms rely on steel foundations<br />

fabricated by Sif Group bv, amongst them the<br />

Horns Rev project in Denmark (the second largest<br />

farm to date) and the Q7 project.<br />

Sif Group bv maintains an effective quality<br />

management system certified in accordance with<br />

the ISO 9001: 2000 standard and with the<br />

implementation of EN-ISO 3834-2 comprehensive<br />

quality requirements for welding. Additional<br />

international approvals and authorisations include:<br />

• Structural tubulars: API Spec. 2B<br />

• Pressure vessel parts: ASME U stamp, ASME<br />

U2 stamp, ASME S stamp, PED 97/23<br />

• Dynamically loaded Steel Structures:<br />

DIN 18800-7 Class E – Ü stamp.<br />

Dimensions, material grades and mechanical<br />

requirements.<br />

The challenging Q7 project involved the manufacture<br />

of 61 mono piles and 61 transition pieces<br />

(60 for the wind farm and one for the transformer<br />

station). Both are tubular structures; the monopiles<br />

are straight and the transition pieces slightly conical.<br />

Figure 3 shows a monopile under construction.<br />

The principal weld connections, the longitudinal<br />

and circumferential welds are clearly visible. The<br />

individual cans are 3–3.5m in length and 4m in<br />

diameter with the longitudinal welds staggered at<br />

180° intervals from can to can. The wall thickness<br />

varies over the length of the monopile, from 45mm<br />

for the thinnest section, to 86mm. Transitions<br />

between differing wall thickness were smoothed by<br />

chamfering (1:5) and/or weld build-up.<br />

Table 1 gives an overview of steel grades and<br />

CVN impact requirements for the several thickness<br />

ranges, both for the transition pieces<br />

Sif fabrication of monopiles and transition<br />

pieces.<br />

The production line starts with beveling by flame cutting<br />

or machining and subsequent cold rolling of<br />

plates to a ring section. With two bending machines,<br />

Sif Group bv can roll plate with a thickness of<br />

20-150mm to shells with a diameter of 0.6 to 8m<br />

and a maximum width of 4.2m (Figure 4). The rolling<br />

process is performed in several steps to achieve the<br />

specified dimensions and roundness; also to facilitate<br />

perfect alignment for high productivity welding.<br />

Tubular structures, in general, and monopiles, in<br />

particular, are straightforward constructions with<br />

heavy longitudinal and circumferential welds. SAW<br />

makes up more than 90% of all welding. Serial<br />

production depends on an efficient factory lay-out<br />

where fabrication is performed in a logical<br />

sequence, minimizing internal transportation of<br />

components. Factory lay-out is also important to<br />

achieve the full production potential offered by the<br />

Table 1. Material grades, thickness and impact requirements<br />

Application Thickness Structural<br />

Category<br />

Material<br />

grade specified<br />

Test<br />

temperature<br />

Impact energy<br />

energy requirements<br />

Transition shell<br />

T< 45 primary S355J2G3- -30°C 34J av. (L)<br />

Td = -10°C<br />

EN10025<br />

24J av. (T)<br />

45