You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Table 2. Weld metal properties at -50°C in 70mm plate from a WPS comparable to the weld of figure 5.<br />

Cv-impact energy [J]<br />

Average<br />

1st welded side V-joint, SAW-twin 2 mm subsurface 111J 94J 90J 98J<br />

2nd welded side U-joint, SAW-triple 2 mm subsurface 110J 102J 104J 105J<br />

Root area 50 mm depth 112J 154J 150J 139J<br />

welding process manually and the system<br />

automatically completes the full welding sequence,<br />

including the positioning of split beads across the<br />

width of the joint. If necessary, the operator can<br />

change to manual control at any time.<br />

Figure 7 shows an example of an absolutely<br />

flawless heavy weld obtained in this manner. Weld<br />

metal properties at -50°C, from a related welding<br />

procedure qualification for Q7 in 70mm plate<br />

thickness, are given in table 2.<br />

Sif Group bv is particularly impressed with the<br />

performance of the ESAB wire feeders on the<br />

narrow gap equipment and the LAF 1250 and<br />

TAF 1250 power sources. The installation<br />

operates 24 hours a day, with minimal<br />

maintenance, and has not given a single problem<br />

over a period of 2 years.<br />

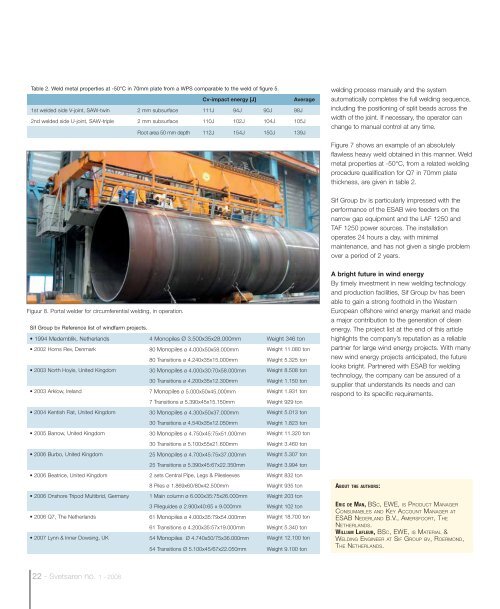

Figuur 8. Portal welder for circumferential welding, in operation.<br />

Sif Group bv Reference list of windfarm projects.<br />

• 1994 Medemblik, Netherlands 4 Monopiles Ø 3.500x35x28.000mm Weight 346 ton<br />

• 2002 Horns Rev, Denmark 80 Monopiles ø 4.000x50x58.000mm Weight 11.080 ton<br />

80 Transitions ø 4.240x35x15.000mm Weight 5.325 ton<br />

• 2003 North Hoyle, United Kingdom 30 Monopiles ø 4.000x30:70x58.000mm Weight 8.508 ton<br />

30 Transitions ø 4.200x35x12.300mm Weight 1.150 ton<br />

• 2003 Arklow, Ireland 7 Monopiles ø 5.000x50x45.000mm Weight 1.931 ton<br />

7 Transitions ø 5.390x45x15.150mm Weight 929 ton<br />

A bright future in wind energy<br />

By timely investment in new welding technology<br />

and production facilities, Sif Group bv has been<br />

able to gain a strong foothold in the Western<br />

European offshore wind energy market and made<br />

a major contribution to the generation of clean<br />

energy. The project list at the end of this article<br />

highlights the company’s reputation as a reliable<br />

partner for large wind energy projects. With many<br />

new wind energy projects anticipated, the future<br />

looks bright. Partnered with ESAB for welding<br />

technology, the company can be assured of a<br />

supplier that understands its needs and can<br />

respond to its specific requirements.<br />

• 2004 Kentish Flat, United Kingdom 30 Monopiles ø 4.300x50x37.000mm Weight 5.013 ton<br />

30 Transitions ø 4.540x35x12.050mm Weight 1.823 ton<br />

• 2005 Barrow, United Kingdom 30 Monopiles ø 4.750x45:75x51.000mm Weight 11.320 ton<br />

30 Transitions ø 5.100x55x21.600mm Weight 3.460 ton<br />

• 2006 Burbo, United Kingdom 25 Monopiles ø 4.700x45:75x37.000mm Weight 5.307 ton<br />

25 Transitions ø 5.390x45:67x22.350mm Weight 3.994 ton<br />

• 2006 Beatrice, United Kingdom 2 sets Central Pipe, Legs & Pilesleeves Weight 832 ton<br />

8 Piles ø 1.869x60/80x42.500mm Weight 935 ton<br />

• 2006 Onshore Tripod Multibrid, Germany 1 Main column ø 6.000x35:75x26.000mm Weight 203 ton<br />

3 Pileguides ø 2.900x40:65 x 9.000mm Weight 102 ton<br />

• 2006 Q7, The Netherlands 61 Monopiles ø 4.000x35:79x54.000mm Weight 18.700 ton<br />

61 Transitions ø 4.200x35:57x19.000mm Weight 5.340 ton<br />

• 2007 Lynn & Inner Dowsing, UK 54 Monopiles Ø 4.740x50/75x36.000mm Weight 12.100 ton<br />

54 Transitions Ø 5.100x45/67x22.050mm Weight 9.100 ton<br />

ABOUT THE AUTHORS:<br />

ERIC DE MAN, BSC, EWE, IS PRODUCT MANAGER<br />

CONSUMABLES AND KEY ACCOUNT MANAGER AT<br />

ESAB NEDERLAND B.V., AMERSFOORT, THE<br />

NETHERLANDS.<br />

WILLIAM LAFLEUR, BSC, EWE, IS MATERIAL &<br />

WELDING ENGINEER AT SIF GROUP BV, ROERMOND,<br />

THE NETHERLANDS.<br />

22 - <strong>Svetsaren</strong> no. 1 - <strong>2008</strong>