HERZ laying system

HERZ laying system

HERZ laying system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

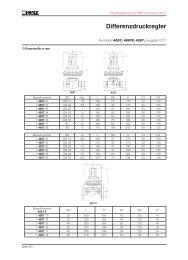

Herz <strong>laying</strong> <strong>system</strong>s<br />

The heating plates are stuck tightly together.<br />

The glue is applied from the cartridge. The<br />

surplus glue is scraped away after drying<br />

out (around 24 hours) with a putty knife or<br />

wooden chisel.<br />

The glue is frost-proof but requires moisture<br />

from the air to set.<br />

Plate customisations must, where possible,<br />

be laid with the cut edge in the direction of<br />

the expansion joint.<br />

The screws for fixing the panels are<br />

countersunk 2 mm and puttied.<br />

When fixing panel sections under 5 cm wide<br />

care must be taken to avoid breakages.<br />

The thin panels could be pre-drilled prior to<br />

fixing.<br />

Fixing of the plaster fibre plates with quick<br />

build screws.<br />

Screw length = plate strength x 2 for metal<br />

frame constructions (30 mm)<br />

Screw length = plate strength x 3 for<br />

wooden constructions (45 mm)<br />

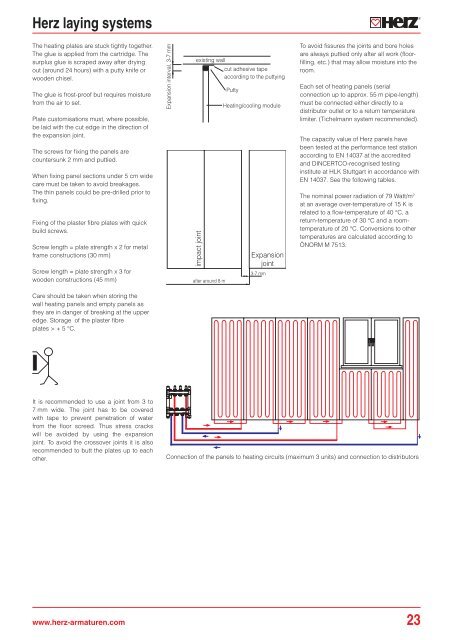

Expansion interval, 3-7 mm<br />

existing wall<br />

cut adhesive tape<br />

according to the puttying<br />

impact joint<br />

after around 8 m<br />

Putty<br />

Heating/cooling module<br />

Expansion<br />

joint<br />

3-7 mm<br />

To avoid fissures the joints and bore holes<br />

are always puttied only after all work (floorfilling,<br />

etc.) that may allow moisture into the<br />

room.<br />

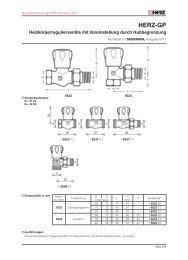

Each set of heating panels (serial<br />

connection up to approx. 55 m pipe-length)<br />

must be connected either directly to a<br />

distributor outlet or to a return temperature<br />

limiter. (Tichelmann <strong>system</strong> recommended).<br />

The capacity value of Herz panels have<br />

been tested at the performance test station<br />

according to EN 14037 at the accredited<br />

and DINCERTCO-recognised testing<br />

institute at HLK Stuttgart in accordance with<br />

EN 14037. See the following tables.<br />

The nominal power radiation of 79 Watt/m 2<br />

at an average over-temperature of 15 K is<br />

related to a fl ow-temperature of 40 °C, a<br />

return-temperature of 30 °C and a roomtemperature<br />

of 20 °C. Conversions to other<br />

temperatures are calculated according to<br />

ÖNORM M 7513.<br />

Care should be taken when storing the<br />

wall heating panels and empty panels as<br />

they are in danger of breaking at the upper<br />

edge. Storage of the plaster fibre<br />

plates > + 5 °C.<br />

It is recommended to use a joint from 3 to<br />

7 mm wide. The joint has to be covered<br />

with tape to prevent penetration of water<br />

from the floor screed. Thus stress cracks<br />

will be avoided by using the expansion<br />

joint. To avoid the crossover joints it is also<br />

recommended to butt the plates up to each<br />

other.<br />

Connection of the panels to heating circuits (maximum 3 units) and connection to distributors<br />

www.herz-armaturen.com 23