Deformation behaviour of railway embankment ... - Liikennevirasto

Deformation behaviour of railway embankment ... - Liikennevirasto

Deformation behaviour of railway embankment ... - Liikennevirasto

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

85<br />

the model parameters, the repeated load triaxial apparatus at Nottingham University<br />

was used.<br />

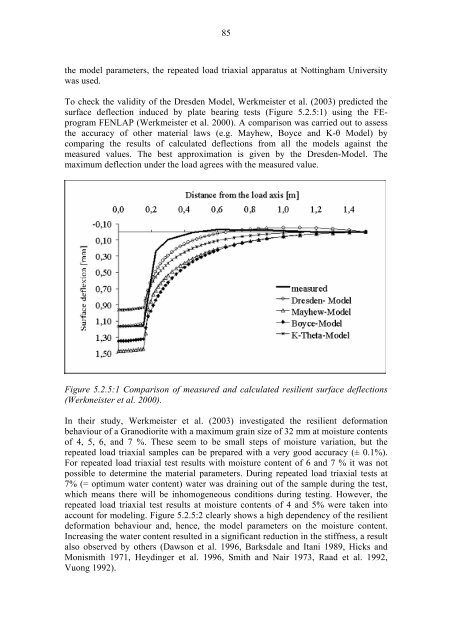

To check the validity <strong>of</strong> the Dresden Model, Werkmeister et al. (2003) predicted the<br />

surface deflection induced by plate bearing tests (Figure 5.2.5:1) using the FEprogram<br />

FENLAP (Werkmeister et al. 2000). A comparison was carried out to assess<br />

the accuracy <strong>of</strong> other material laws (e.g. Mayhew, Boyce and K-θ Model) by<br />

comparing the results <strong>of</strong> calculated deflections from all the models against the<br />

measured values. The best approximation is given by the Dresden-Model. The<br />

maximum deflection under the load agrees with the measured value.<br />

Figure 5.2.5:1 Comparison <strong>of</strong> measured and calculated resilient surface deflections<br />

(Werkmeister et al. 2000).<br />

In their study, Werkmeister et al. (2003) investigated the resilient deformation<br />

<strong>behaviour</strong> <strong>of</strong> a Granodiorite with a maximum grain size <strong>of</strong> 32 mm at moisture contents<br />

<strong>of</strong> 4, 5, 6, and 7 %. These seem to be small steps <strong>of</strong> moisture variation, but the<br />

repeated load triaxial samples can be prepared with a very good accuracy (± 0.1%).<br />

For repeated load triaxial test results with moisture content <strong>of</strong> 6 and 7 % it was not<br />

possible to determine the material parameters. During repeated load triaxial tests at<br />

7% (= optimum water content) water was draining out <strong>of</strong> the sample during the test,<br />

which means there will be inhomogeneous conditions during testing. However, the<br />

repeated load triaxial test results at moisture contents <strong>of</strong> 4 and 5% were taken into<br />

account for modeling. Figure 5.2.5:2 clearly shows a high dependency <strong>of</strong> the resilient<br />

deformation <strong>behaviour</strong> and, hence, the model parameters on the moisture content.<br />

Increasing the water content resulted in a significant reduction in the stiffness, a result<br />

also observed by others (Dawson et al. 1996, Barksdale and Itani 1989, Hicks and<br />

Monismith 1971, Heydinger et al. 1996, Smith and Nair 1973, Raad et al. 1992,<br />

Vuong 1992).