Deformation behaviour of railway embankment ... - Liikennevirasto

Deformation behaviour of railway embankment ... - Liikennevirasto

Deformation behaviour of railway embankment ... - Liikennevirasto

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

97<br />

using the ultimate shear strength <strong>of</strong> the material. In this approach, the static failure line<br />

is considered as a boundary for permanent strain under repeated loading. This has been<br />

questioned by Lekarp and Dawson (1998), who argue that failure in granular materials<br />

under repeated loading is a gradual process and not a sudden collapse as in static failure<br />

tests. Therefore, the ultimate shear strength and stress levels that cause sudden failure<br />

are <strong>of</strong> no great interest for the analysis <strong>of</strong> the material <strong>behaviour</strong> when the increase in<br />

permanent strain is incremental.<br />

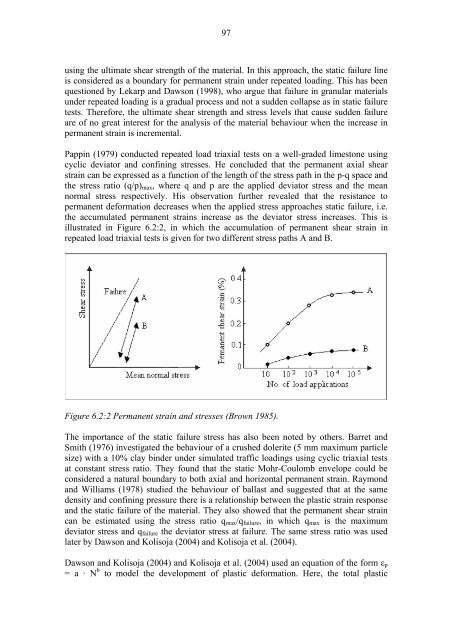

Pappin (1979) conducted repeated load triaxial tests on a well-graded limestone using<br />

cyclic deviator and confining stresses. He concluded that the permanent axial shear<br />

strain can be expressed as a function <strong>of</strong> the length <strong>of</strong> the stress path in the p-q space and<br />

the stress ratio (q/p) max , where q and p are the applied deviator stress and the mean<br />

normal stress respectively. His observation further revealed that the resistance to<br />

permanent deformation decreases when the applied stress approaches static failure, i.e.<br />

the accumulated permanent strains increase as the deviator stress increases. This is<br />

illustrated in Figure 6.2:2, in which the accumulation <strong>of</strong> permanent shear strain in<br />

repeated load triaxial tests is given for two different stress paths A and B.<br />

Figure 6.2:2 Permanent strain and stresses (Brown 1985).<br />

The importance <strong>of</strong> the static failure stress has also been noted by others. Barret and<br />

Smith (1976) investigated the <strong>behaviour</strong> <strong>of</strong> a crushed dolerite (5 mm maximum particle<br />

size) with a 10% clay binder under simulated traffic loadings using cyclic triaxial tests<br />

at constant stress ratio. They found that the static Mohr-Coulomb envelope could be<br />

considered a natural boundary to both axial and horizontal permanent strain. Raymond<br />

and Williams (1978) studied the <strong>behaviour</strong> <strong>of</strong> ballast and suggested that at the same<br />

density and confining pressure there is a relationship between the plastic strain response<br />

and the static failure <strong>of</strong> the material. They also showed that the permanent shear strain<br />

can be estimated using the stress ratio q max /q failure , in which q max is the maximum<br />

deviator stress and q failure the deviator stress at failure. The same stress ratio was used<br />

later by Dawson and Kolisoja (2004) and Kolisoja et al. (2004).<br />

Dawson and Kolisoja (2004) and Kolisoja et al. (2004) used an equation <strong>of</strong> the form ε p<br />

= a · N b to model the development <strong>of</strong> plastic deformation. Here, the total plastic