Deformation behaviour of railway embankment ... - Liikennevirasto

Deformation behaviour of railway embankment ... - Liikennevirasto

Deformation behaviour of railway embankment ... - Liikennevirasto

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

94<br />

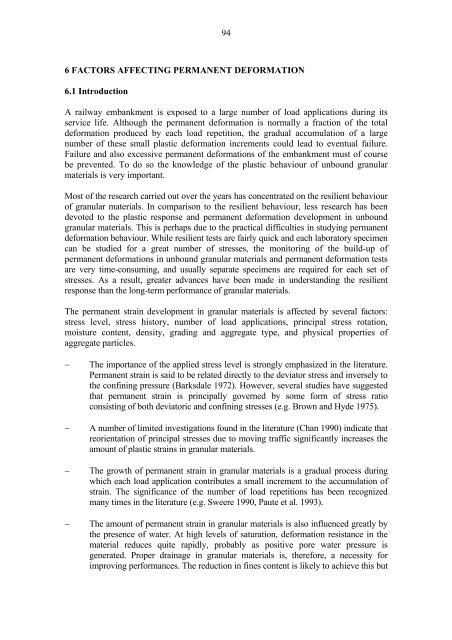

6 FACTORS AFFECTING PERMANENT DEFORMATION<br />

6.1 Introduction<br />

A <strong>railway</strong> <strong>embankment</strong> is exposed to a large number <strong>of</strong> load applications during its<br />

service life. Although the permanent deformation is normally a fraction <strong>of</strong> the total<br />

deformation produced by each load repetition, the gradual accumulation <strong>of</strong> a large<br />

number <strong>of</strong> these small plastic deformation increments could lead to eventual failure.<br />

Failure and also excessive permanent deformations <strong>of</strong> the <strong>embankment</strong> must <strong>of</strong> course<br />

be prevented. To do so the knowledge <strong>of</strong> the plastic <strong>behaviour</strong> <strong>of</strong> unbound granular<br />

materials is very important.<br />

Most <strong>of</strong> the research carried out over the years has concentrated on the resilient <strong>behaviour</strong><br />

<strong>of</strong> granular materials. In comparison to the resilient <strong>behaviour</strong>, less research has been<br />

devoted to the plastic response and permanent deformation development in unbound<br />

granular materials. This is perhaps due to the practical difficulties in studying permanent<br />

deformation <strong>behaviour</strong>. While resilient tests are fairly quick and each laboratory specimen<br />

can be studied for a great number <strong>of</strong> stresses, the monitoring <strong>of</strong> the build-up <strong>of</strong><br />

permanent deformations in unbound granular materials and permanent deformation tests<br />

are very time-consuming, and usually separate specimens are required for each set <strong>of</strong><br />

stresses. As a result, greater advances have been made in understanding the resilient<br />

response than the long-term performance <strong>of</strong> granular materials.<br />

The permanent strain development in granular materials is affected by several factors:<br />

stress level, stress history, number <strong>of</strong> load applications, principal stress rotation,<br />

moisture content, density, grading and aggregate type, and physical properties <strong>of</strong><br />

aggregate particles.<br />

−<br />

−<br />

−<br />

−<br />

The importance <strong>of</strong> the applied stress level is strongly emphasized in the literature.<br />

Permanent strain is said to be related directly to the deviator stress and inversely to<br />

the confining pressure (Barksdale 1972). However, several studies have suggested<br />

that permanent strain is principally governed by some form <strong>of</strong> stress ratio<br />

consisting <strong>of</strong> both deviatoric and confining stresses (e.g. Brown and Hyde 1975).<br />

A number <strong>of</strong> limited investigations found in the literature (Chan 1990) indicate that<br />

reorientation <strong>of</strong> principal stresses due to moving traffic significantly increases the<br />

amount <strong>of</strong> plastic strains in granular materials.<br />

The growth <strong>of</strong> permanent strain in granular materials is a gradual process during<br />

which each load application contributes a small increment to the accumulation <strong>of</strong><br />

strain. The significance <strong>of</strong> the number <strong>of</strong> load repetitions has been recognized<br />

many times in the literature (e.g. Sweere 1990, Paute et al. 1993).<br />

The amount <strong>of</strong> permanent strain in granular materials is also influenced greatly by<br />

the presence <strong>of</strong> water. At high levels <strong>of</strong> saturation, deformation resistance in the<br />

material reduces quite rapidly, probably as positive pore water pressure is<br />

generated. Proper drainage in granular materials is, therefore, a necessity for<br />

improving performances. The reduction in fines content is likely to achieve this but