ENVIRONMENTAL STATEMENT BARDOLINO DEVELOPMENT

ENVIRONMENTAL STATEMENT BARDOLINO DEVELOPMENT

ENVIRONMENTAL STATEMENT BARDOLINO DEVELOPMENT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

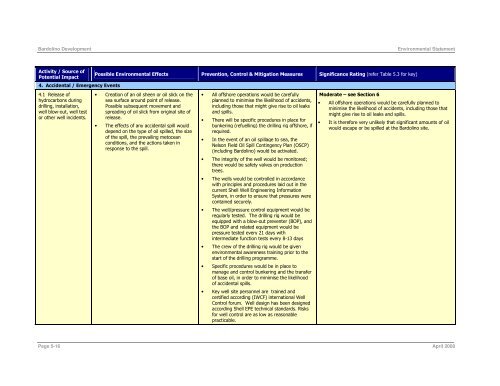

Bardolino Development Environmental Statement<br />

Activity / Source of<br />

Potential Impact<br />

4. Accidental / Emergency Events<br />

4.1 Release of<br />

hydrocarbons during<br />

drilling, installation,<br />

well blow-out, well test<br />

or other well incidents.<br />

Possible Environmental Effects Prevention, Control & Mitigation Measures Significance Rating (refer Table 5.3 for key)<br />

• Creation of an oil sheen or oil slick on the<br />

sea surface around point of release.<br />

Possible subsequent movement and<br />

spreading of oil slick from original site of<br />

release.<br />

• The effects of any accidental spill would<br />

depend on the type of oil spilled, the size<br />

of the spill, the prevailing metocean<br />

conditions, and the actions taken in<br />

response to the spill.<br />

• All offshore operations would be carefully<br />

planned to minimise the likelihood of accidents,<br />

including those that might give rise to oil leaks<br />

and spills.<br />

• There will be specific procedures in place for<br />

bunkering (refuelling) the drilling rig offshore, if<br />

required.<br />

• In the event of an oil spillage to sea, the<br />

Nelson Field Oil Spill Contingency Plan (OSCP)<br />

(including Bardolino) would be activated.<br />

• The integrity of the well would be monitored;<br />

there would be safety valves on production<br />

trees.<br />

• The wells would be controlled in accordance<br />

with principles and procedures laid out in the<br />

current Shell Well Engineering Information<br />

System, in order to ensure that pressures were<br />

contained securely.<br />

• The well/pressure control equipment would be<br />

regularly tested. The drilling rig would be<br />

equipped with a blow-out preventer (BOP), and<br />

the BOP and related equipment would be<br />

pressure tested every 21 days with<br />

intermediate function tests every 8-13 days<br />

• The crew of the drilling rig would be given<br />

environmental awareness training prior to the<br />

start of the drilling programme.<br />

• Specific procedures would be in place to<br />

manage and control bunkering and the transfer<br />

of base oil, in order to minimise the likelihood<br />

of accidental spills.<br />

• Key well site personnel are trained and<br />

certified according (IWCF) international Well<br />

Control forum. Well design has been designed<br />

according Shell EPE technical standards. Risks<br />

for well control are as low as reasonable<br />

practicable.<br />

Moderate – see Section 6<br />

• All offshore operations would be carefully planned to<br />

minimise the likelihood of accidents, including those that<br />

might give rise to oil leaks and spills.<br />

• It is therefore very unlikely that significant amounts of oil<br />

would escape or be spilled at the Bardolino site.<br />

Page 5-16 April 2008

![Download Shell AutoGas Stationen [Stand: Januar 2013] (PDF](https://img.yumpu.com/9982753/1/190x245/download-shell-autogas-stationen-stand-januar-2013-pdf.jpg?quality=85)